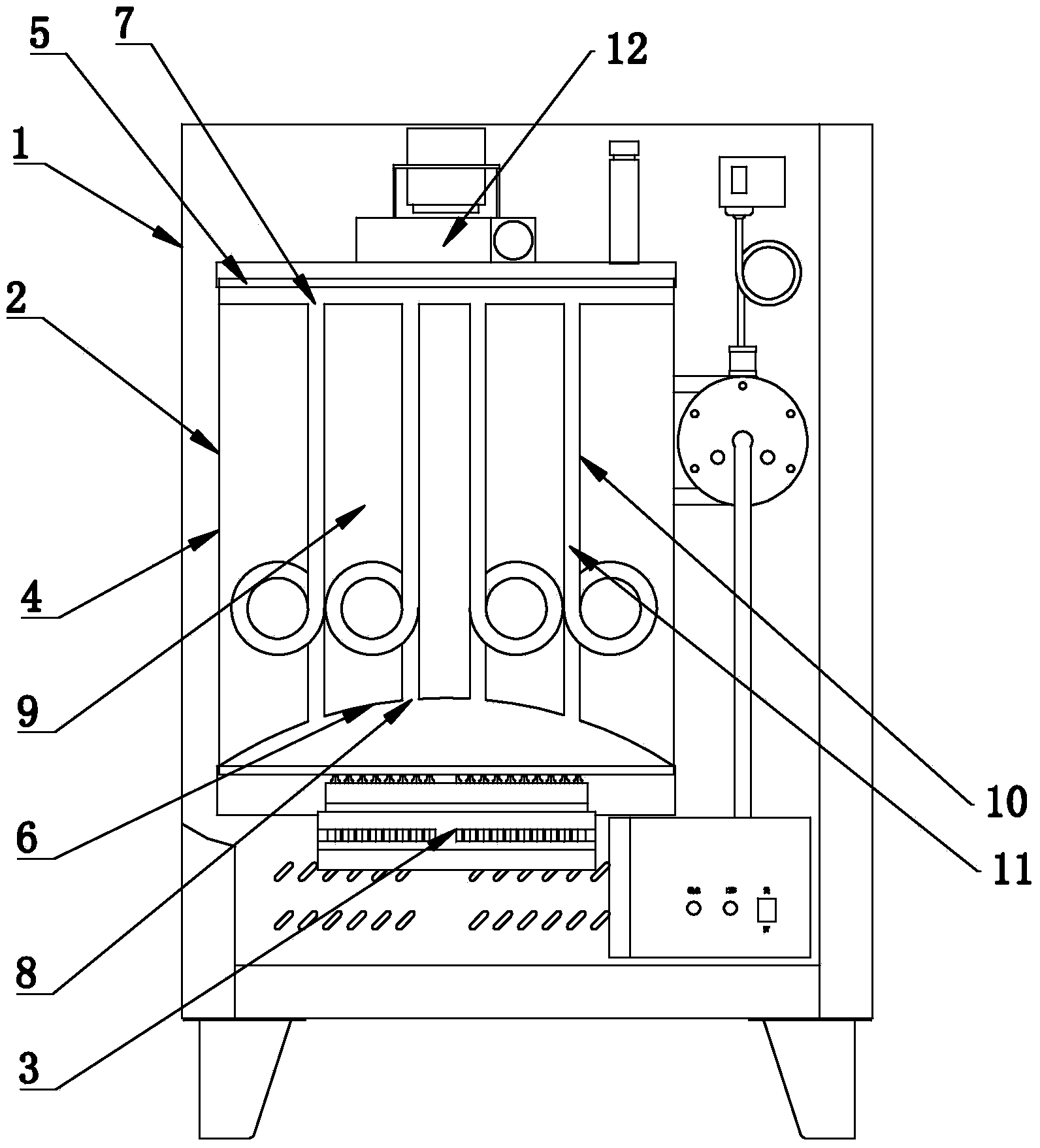

Vapor generator

A technology of a steam generator and a heating pipe is applied in the field of kitchen utensils and can solve the problems of low utilization rate of heat energy of the steam generator and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

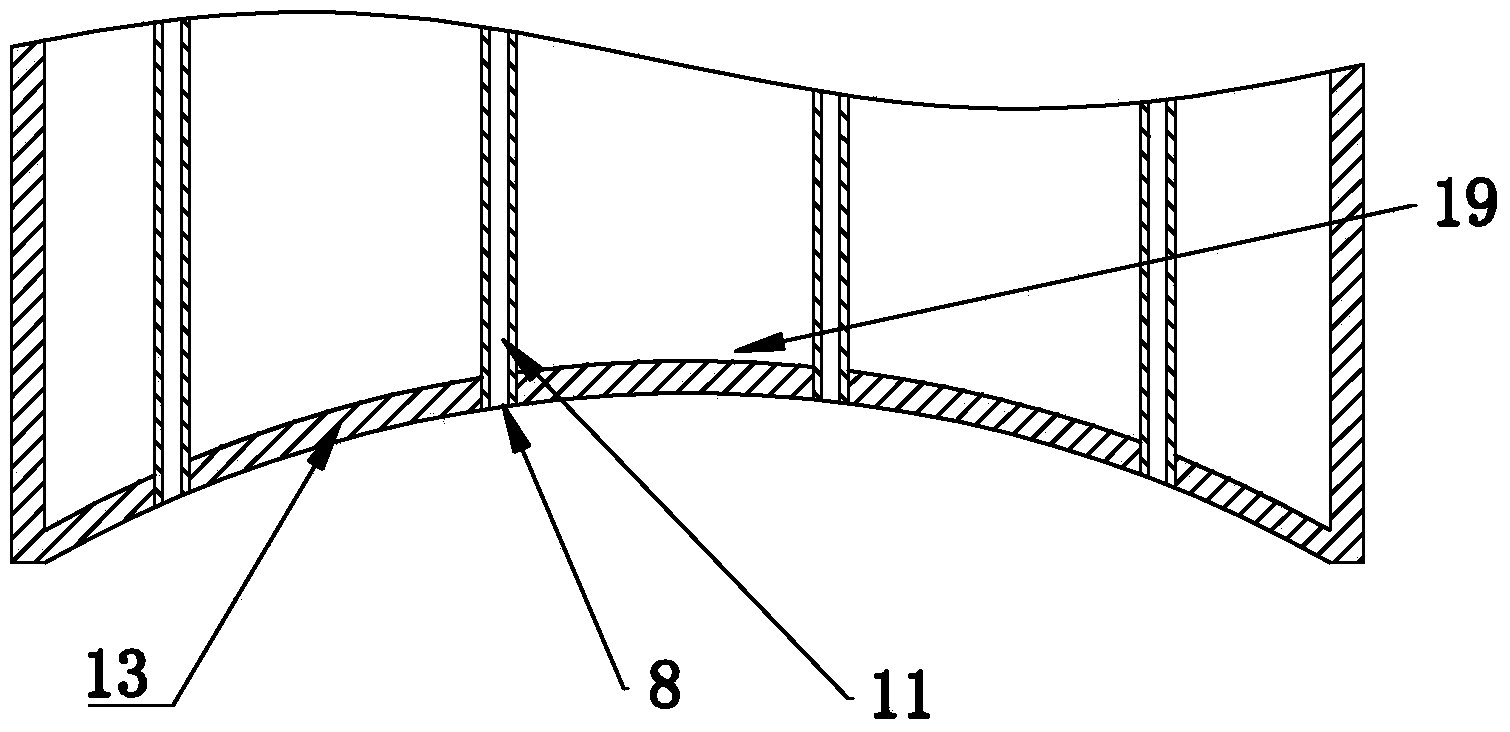

[0038] In Embodiment 1, the heating surface 6 is an arc-shaped heating surface 13 , and the arc-shaped heating surface 13 includes a protruding portion 19 , and the protruding portion 19 is disposed toward the side of the upper hole 7 .

[0039] The arc-shaped heating surface 13 is curved toward the upper hole 7, so it is arc-shaped. Since the area of the arc-shaped surface is larger than the area of the plane, the area of the arc-shaped heating surface 13 is larger. When the flame generated by the burner 3 acts on the arc-shaped heating surface 13, can effectively increase the heating area, and also has the effect of uniform heating.

Embodiment 2

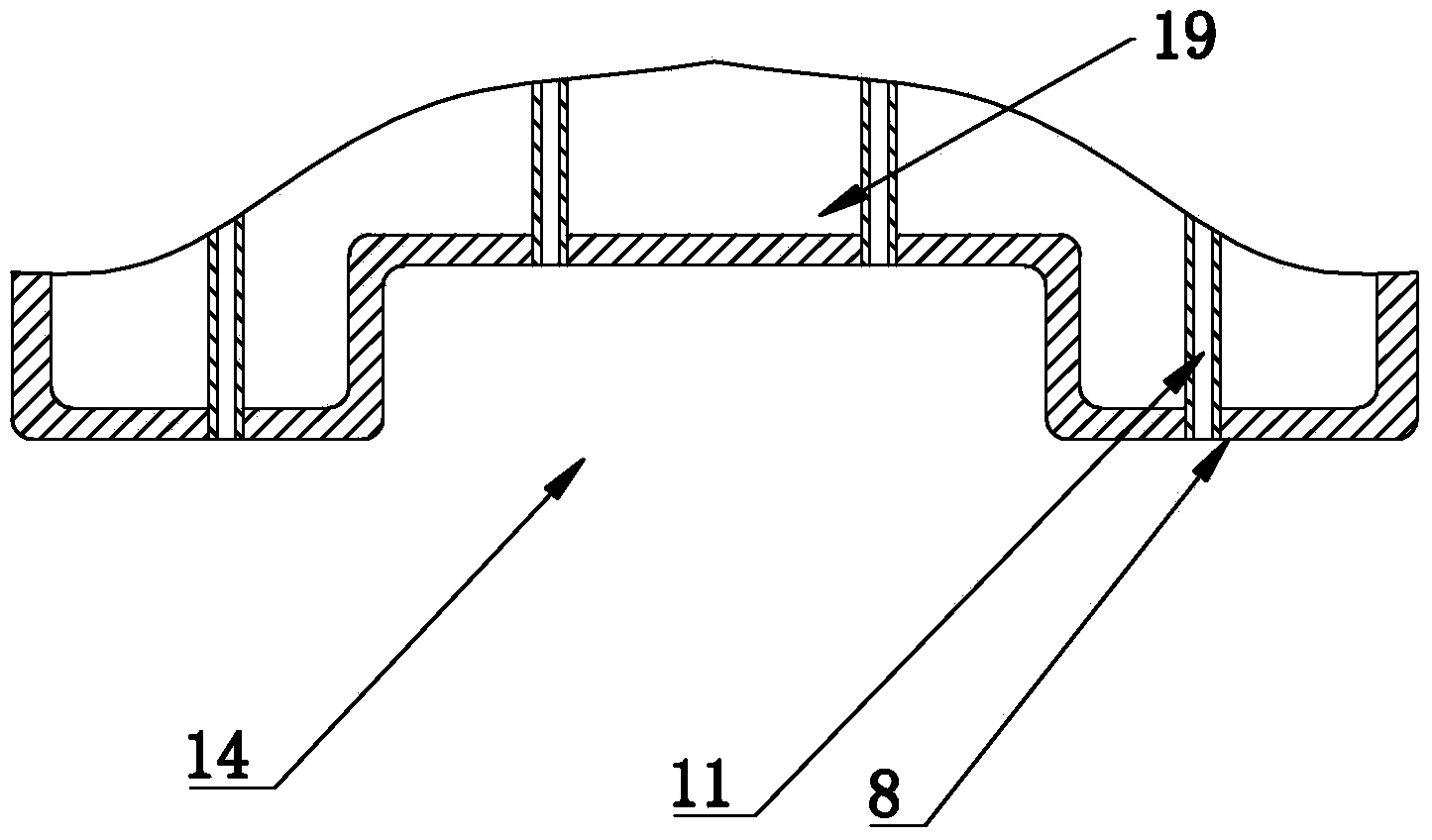

[0040] In the second embodiment, the heating surface 6 is a stepped heating surface 14, and the stepped heating surface 14 includes a protruding portion 19, and the protruding portion 19 is arranged toward the upper hole 7 side.

[0041] Since the heating surface 6 is continuously folded toward the upper hole 7 and is stepped, the area of the stepped heating surface 14 is larger than that of the plane. When the flame generated by the burner 3 acts on the stepped heating surface 14, it can effectively increase the heating area, and also has the effect of uniform heating.

Embodiment 3

[0042] In the third embodiment, the heating pipe 10 is a spiral heating pipe 15, the water tank 2 is cylindrical, and the spiral heating pipe 15 is provided with a spiral part 16 spiraling around the axis of the water tank 2 inside the water tank 2.

[0043] Since the helical part 16 is spirally formed on the helical heating tube 15, the helical part 16 can increase the contact area between the helical heating tube 15 and the water, thereby effectively heating the water in the accommodating chamber 9, and prolonging the length of the hot air channel 11 to increase the temperature of the high-temperature air. The residence time in the hot air channel 11, so that the high temperature air has enough time to transfer heat; when the water tank 2 is in the shape of a barrel, and the heating pipe 10 is a spiral heating pipe 15, the spiral part 16 is spirally arranged around the axis, The axis of the spiral portion 16 is arranged coaxially with the axis of the water tank 2. When the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com