Method for testing low-frequency noise of amorphous silicon membrane

A technology of amorphous silicon thin film and testing method, which is applied in the direction of noise figure or signal-to-noise ratio measurement, etc., can solve problems such as inability to quickly and effectively collect and process data, slow data acquisition speed, and influence of power frequency noise, so as to reduce the background Effects of noise and power frequency noise, fast acquisition, and interference reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

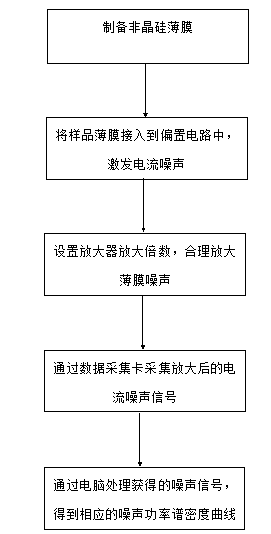

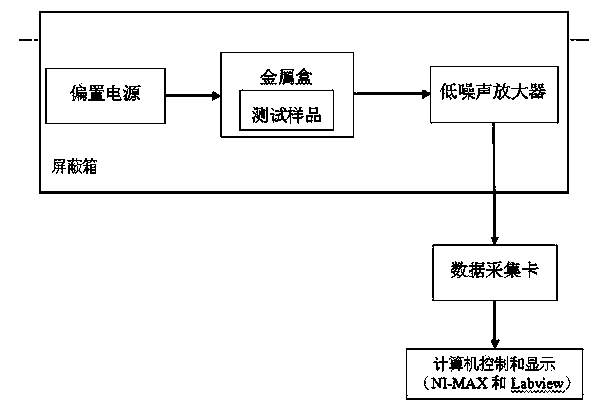

[0054] In order to make the purpose and technical solution of the low-frequency noise testing method for an amorphous silicon thin film clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

Embodiment

[0055] Example object: 5% P-doped hydrogenated amorphous silicon film;

[0056] Example conditions: at a room temperature of 300K, a test voltage of 7V is applied to both ends of the amorphous silicon thin film sample, and the current amplifier multiple is 50nA / V;

[0057] The specific process is as follows:

[0058] Step 1: Put the amorphous silicon film to be tested into a metal box and fix it, connect the lead wires into the circuit, apply a DC voltage of 7V to the amorphous silicon film sample to stimulate the amorphous silicon film current noise signal;

[0059] Step 2: Connect the bias circuit, current amplifier and data acquisition card through the coaxial cable interface, open the Labview test software and the amplifier, adjust the amplification factor of the current amplifier, and ensure that the input current of the amplifier and the amplified output voltage are within the range of the amplifier Under the conditions within, make the amplified signal gradually incre...

Embodiment 2

[0063] In order to make the purpose and technical solution of the low-frequency noise testing method for an amorphous silicon thin film clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0064] Example object: 1% Ru (ruthenium) doped amorphous silicon film, and annealed at 700 ° C;

[0065] Example conditions: at room temperature, the sample voltage is 10V, and the amplification factor is 50nA / V;

[0066] The specific process is as follows:

[0067] Step 1: Put the amorphous silicon film to be tested into a metal box and fix it, connect the lead wires to the circuit, and apply a 10V DC voltage to the amorphous silicon film sample to stimulate the amorphous silicon film. current noise signal;

[0068] Step 2: Connect the bias circuit, current amplifier and data acquisition card through the coaxial cable interface, open the Labview test software and the amplifier, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com