Plate-frame type PTFE membrane deduster

A dust collector, plate-and-frame technology, applied in the direction of gas dust removal, chemical instruments and methods, separation of dispersed particles, etc., can solve the problem that the gas can only pass through the dust collector once, it is difficult to overcome the dependence on the dust layer, and it is difficult to remove fine particles , to achieve the effect of small footprint, simple structure and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

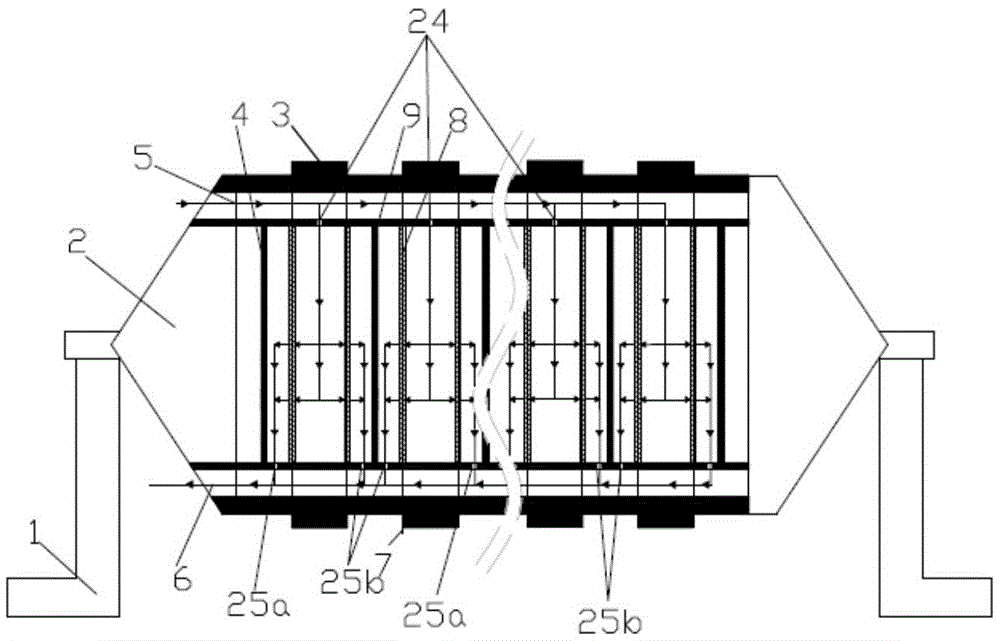

[0026] In the following, the plate and frame type PTFE membrane dust collector of the present invention will be further described in detail with reference to the accompanying drawings:

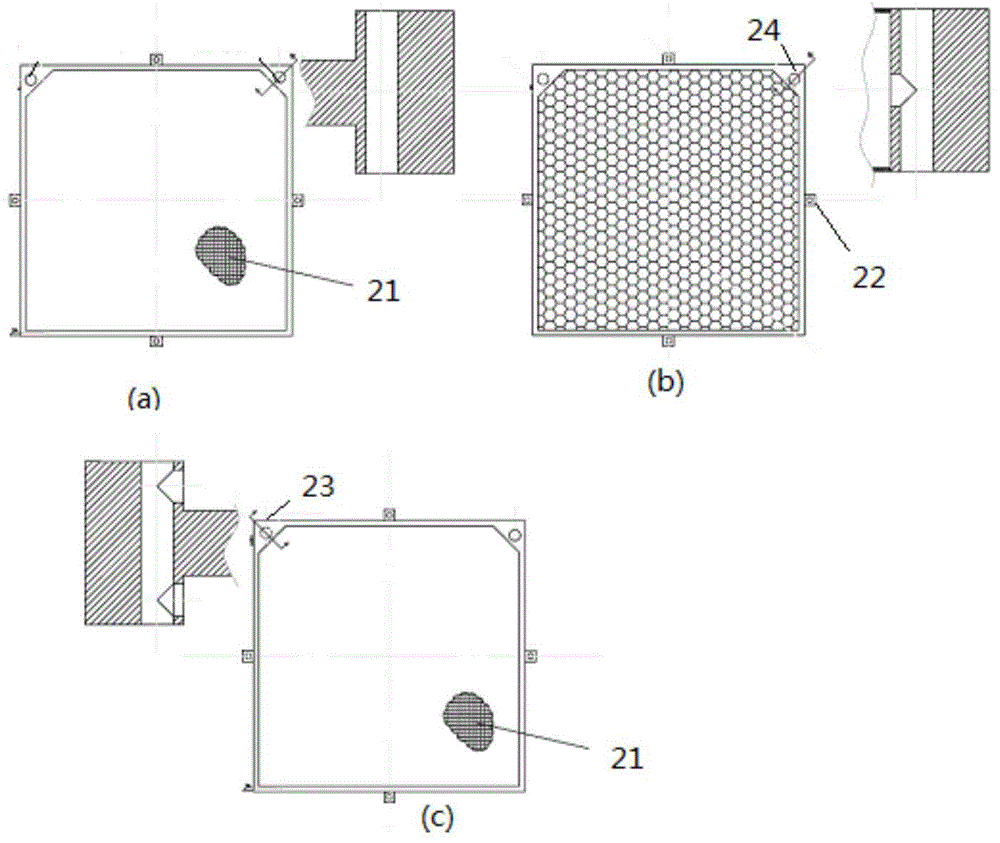

[0027] Such as figure 1 , 2 Shown. The dust remover includes one or more dust removal structures; the dust removal structure is a closed space formed by the connection of the dust removal plate 4, the dust removal frame 3, and the purge plate 9, according to the dust removal plate 4—dust removal frame 3—purge board 9—dust removal Frame 3—Dust removal plate 4 is assembled in sequence. The middle of the dust removal frame is an empty frame, and both sides of the dust removal frame are covered by PTFE microporous membrane 7; the dust removal plate and the purge plate are in the shape of "I" in longitudinal section For solid partitions, the dust removal plate, dust removal frame and sweeping plate of the plate and frame type dust collector are usually square. In addition, the dust removal plate and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com