Device for constant high-temperature treatment prior to garbage incineration and flue gas purification

A flue gas purification and high-temperature treatment technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problem of high cost, and achieve the effect of fast heating speed, small temperature gradient of flue gas, and small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

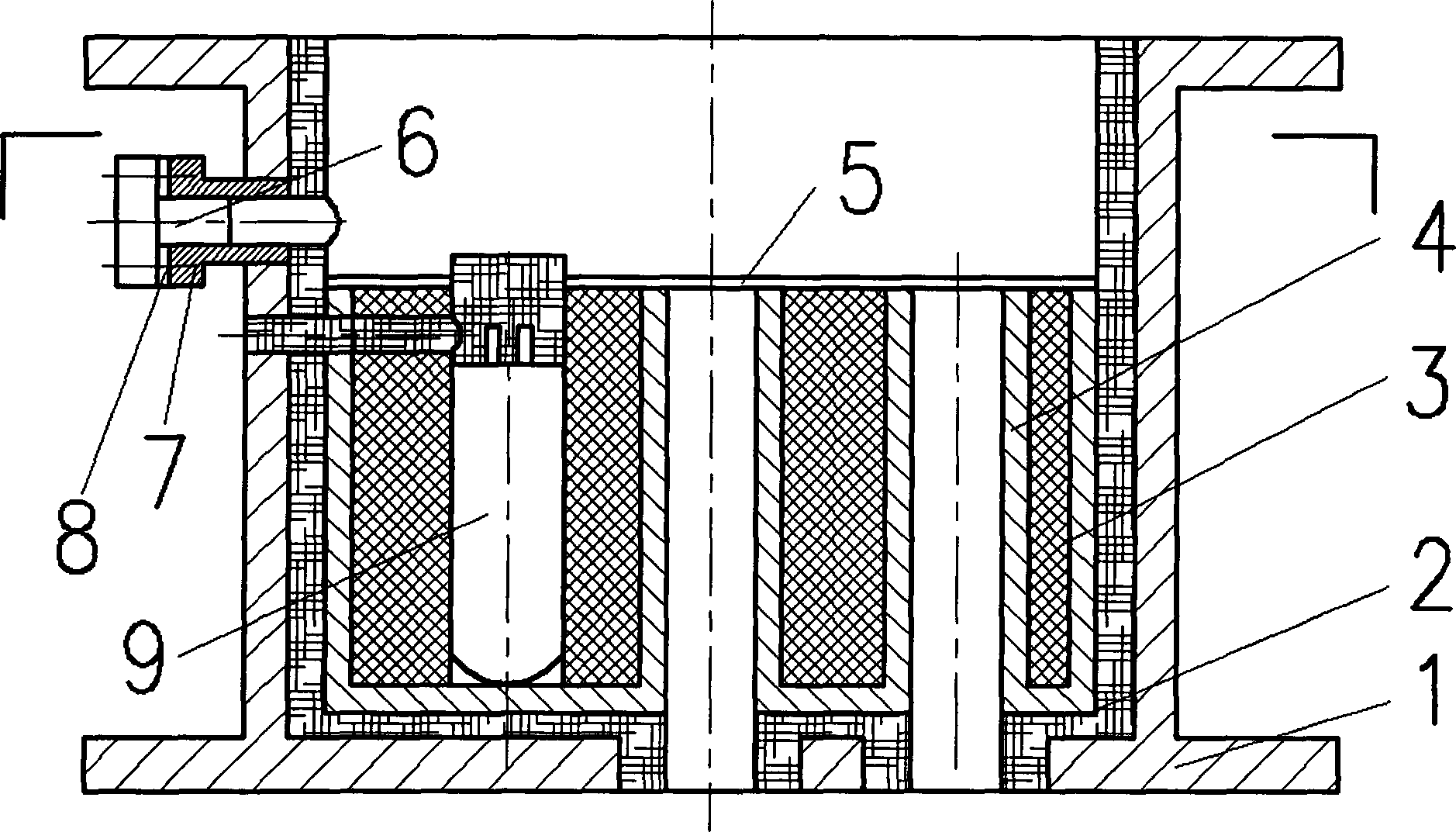

[0027] Below is working principle and working process of the present invention:

[0028] Before incineration in the waste incinerator, according to the heat capacity of the shaped high-temperature composite phase-change thermal storage material 3, determine the total power of the four electric heating tubes 9, and simultaneously electrify the four electric heating tubes 9, and heat for 5 minutes to make the shaped high-temperature composite phase-change thermal storage material 3. About 50% of the high-temperature phase-change thermal storage materials are transformed into liquid at 850°C, and then start to incinerate garbage.

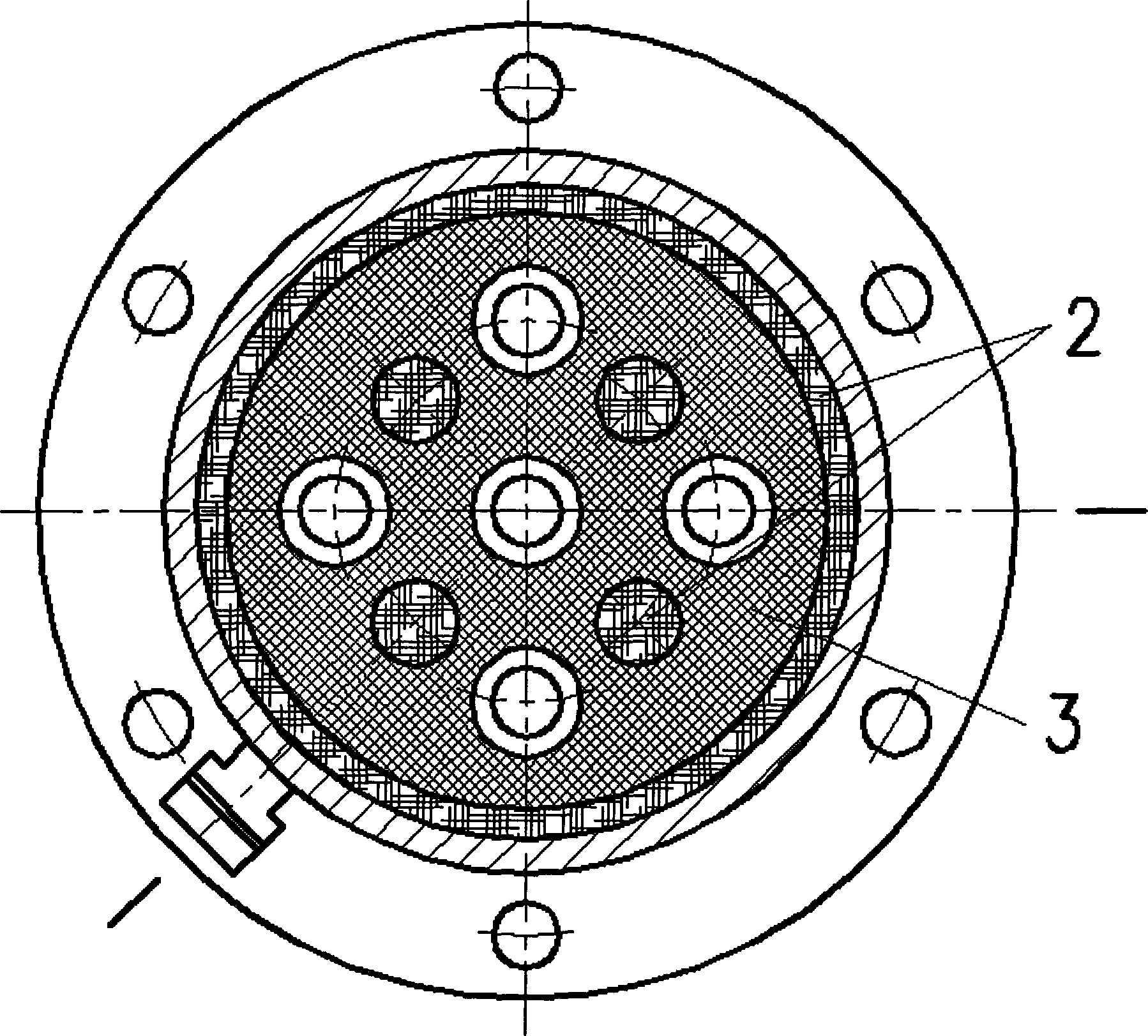

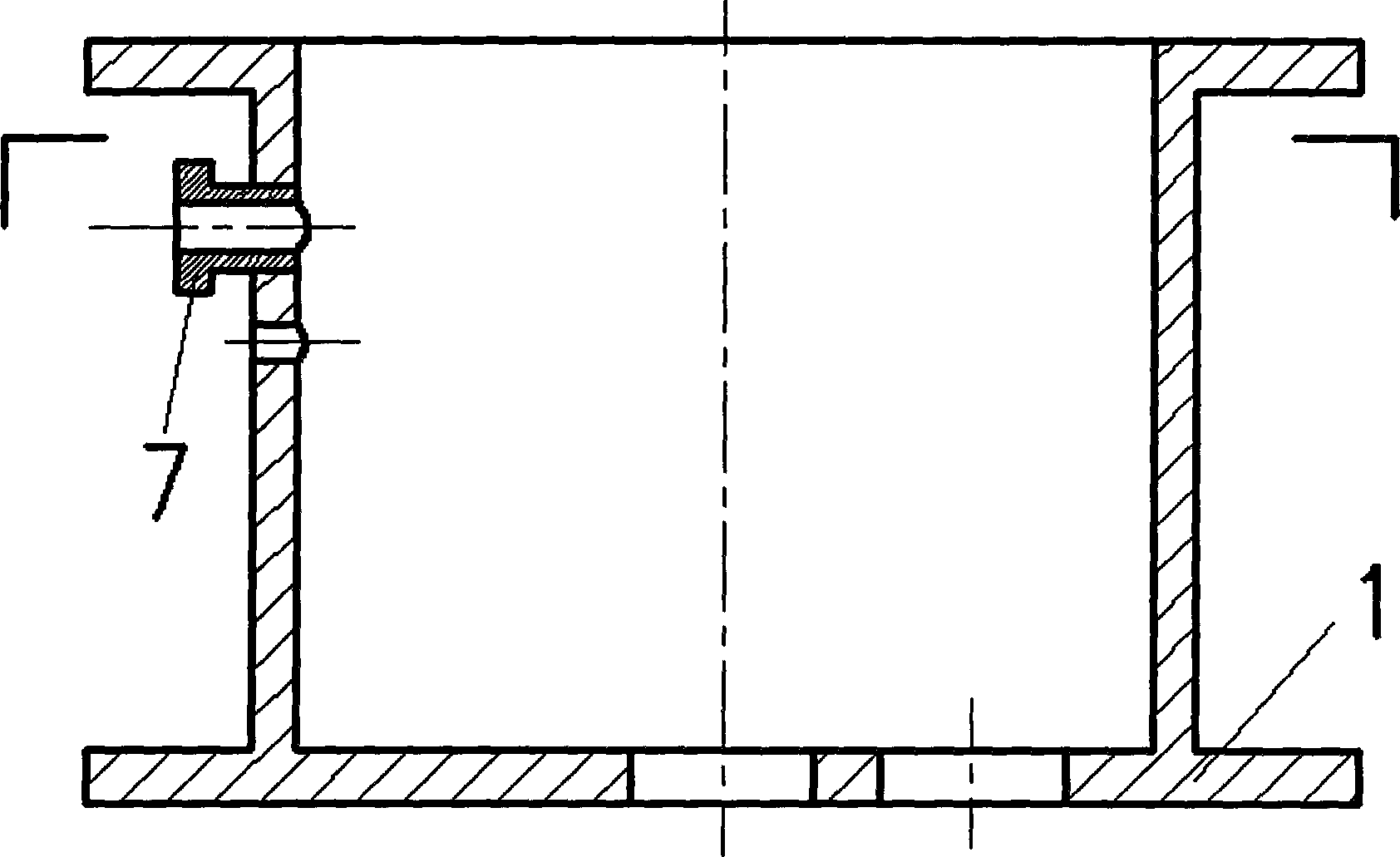

[0029] The holding cylinder 4 has five vertical column holes for passing the flue gas and using the shaped high-temperature composite phase change heat storage material 3 to heat the flue gas below 850°C to make the flue gas 850°C. According to the flow rate of the flue gas, the height of the vertical column hole ensures that the flue gas stays in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com