Heterogeneous material tailor-welded blank hot stamping forming device and method with controllable temperature field

A technology for hot stamping and tailor welded blanks, which is applied in the field of hot stamping forming devices for tailor welded blanks of different materials, which can solve the problems of poor hot stamping forming effect, uncontrollable local forming temperature, failure of hot stamping forming, etc., and achieve high heating efficiency , Realize the effect of automation and continuous, fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

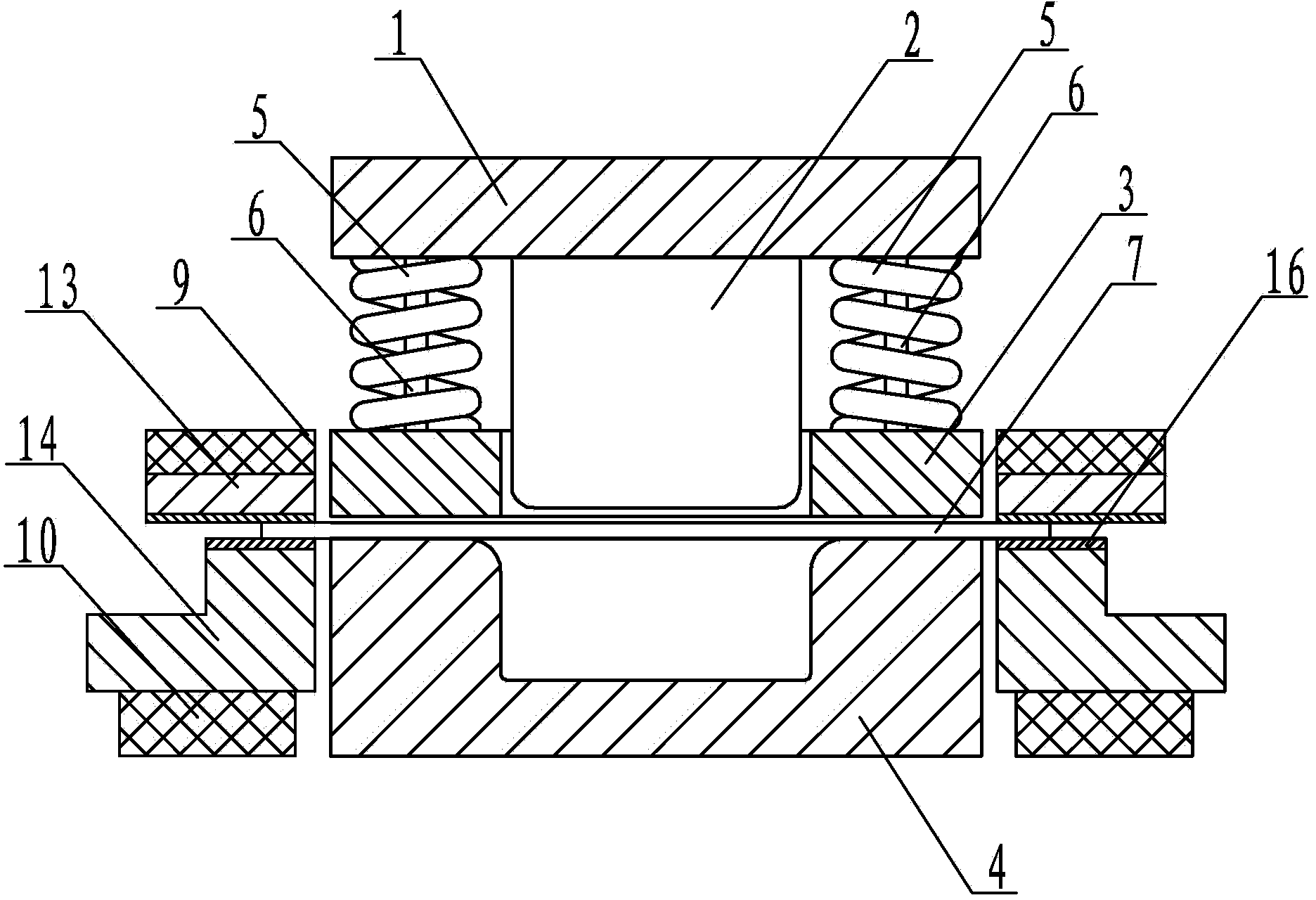

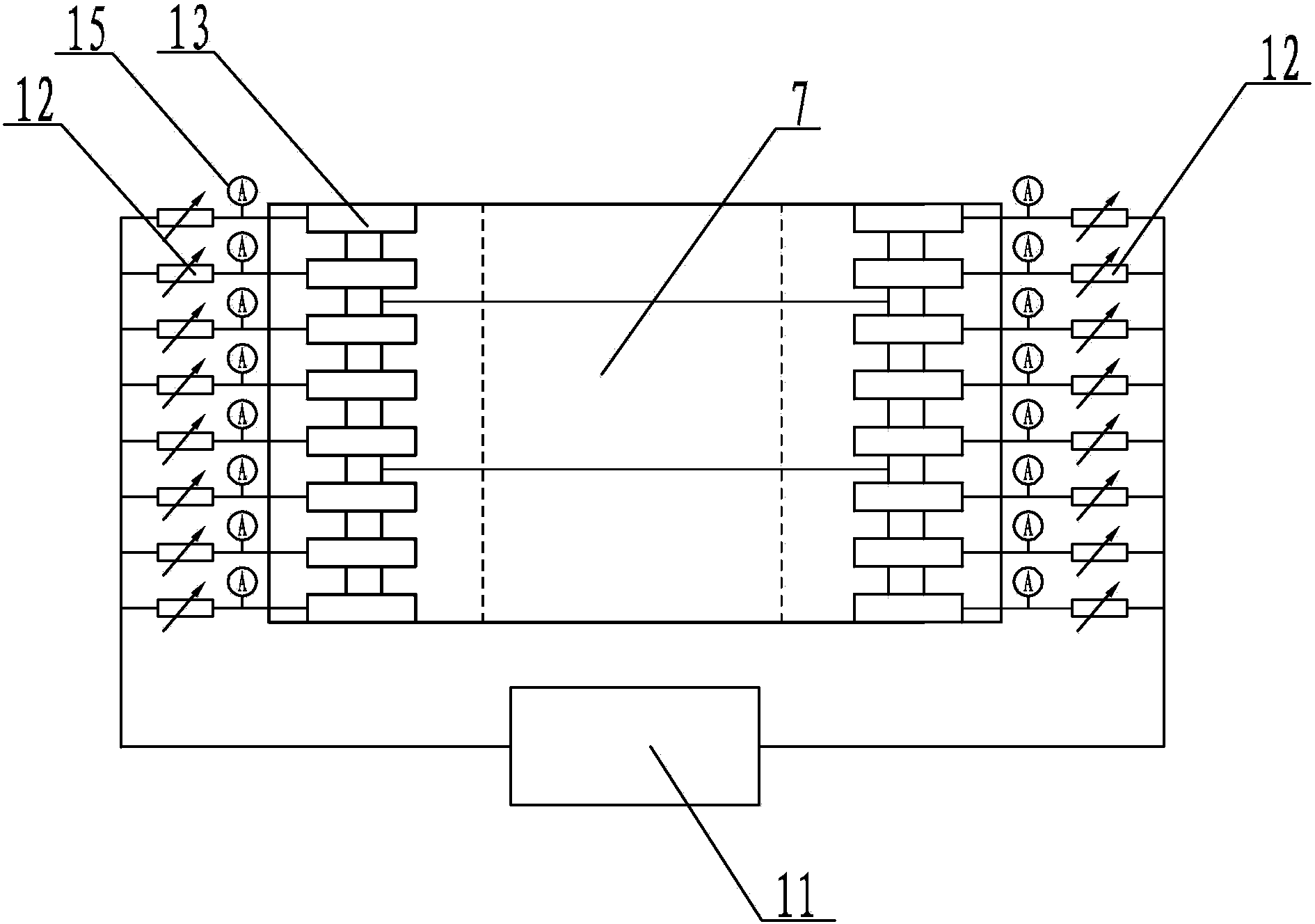

[0027] Specific implementation mode one: combine Figure 1-Figure 2 To illustrate this embodiment, a thermal stamping device for tailor-welded blanks of different materials with controllable temperature field in this embodiment includes a forming die, and the forming die includes a convex plate 1, a punch 2, a blank holder 3, and a die 4 , a plurality of springs 5 and a plurality of studs 6 with the same number as the springs 5, the punch plate 1, the blank holder 3 and the die 4 are arranged in parallel from top to bottom, and the punch 2 is fixedly arranged on the bottom surface of the punch plate 1 At the center position, a plurality of studs 6 are first passed through the counterbore of the convex formwork 1 from top to bottom, and then screwed on the blank holder 3, and the gap between the upper parts of the plurality of studs 6 and the convex formwork 1 Cooperate, each stud 6 is fitted with a spring 5, and the tailor welded blank 7 of dissimilar material is arranged be...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination Figure 1-Figure 2 To describe this embodiment, the material of the plurality of segmented adjustable electrodes 13 and the two clamping electrodes 14 in this embodiment is copper. With such setting, the resistivity of red copper is small, the melting point is high, and the power consumption is small. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0030]Specific implementation mode three: combination Figure 1-Figure 2 To illustrate this embodiment, the hot stamping forming device for tailor-welded blanks made of different materials in this embodiment also includes a plurality of titanium alloy insulation sheets 16, the lower end surfaces of the two rows of segmented adjustable electrodes and the upper end surfaces of the tailor-welded blanks 7 made of different materials A titanium alloy insulation sheet 16 is provided between them, and two titanium alloy insulation sheets 16 are provided between the upper end surfaces of the two clamping electrodes 14 and the lower end surface of the tailored welded blank 7 made of different materials. With such arrangement, the titanium alloy has high resistivity and poor thermal conductivity, which can prevent the heat on the tailor-welded blank 7 of dissimilar materials from being dissipated to the outside through the red copper electrode, and has a good heat preservation effect. O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com