Method for manufacturing special-shaped ring forge piece of large wind power flange

A manufacturing method and a special-shaped ring technology, which are applied in the manufacturing field of large-scale wind tower flange special-shaped ring forgings, can solve the problems of poor rolling process stability, large consumption of raw materials, low production efficiency, etc., and achieve high production efficiency and finishing man-hours. Less, good flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The manufacturing method of the large-scale wind tower flange special-shaped ring forging according to the present invention will be further described in detail through specific examples below.

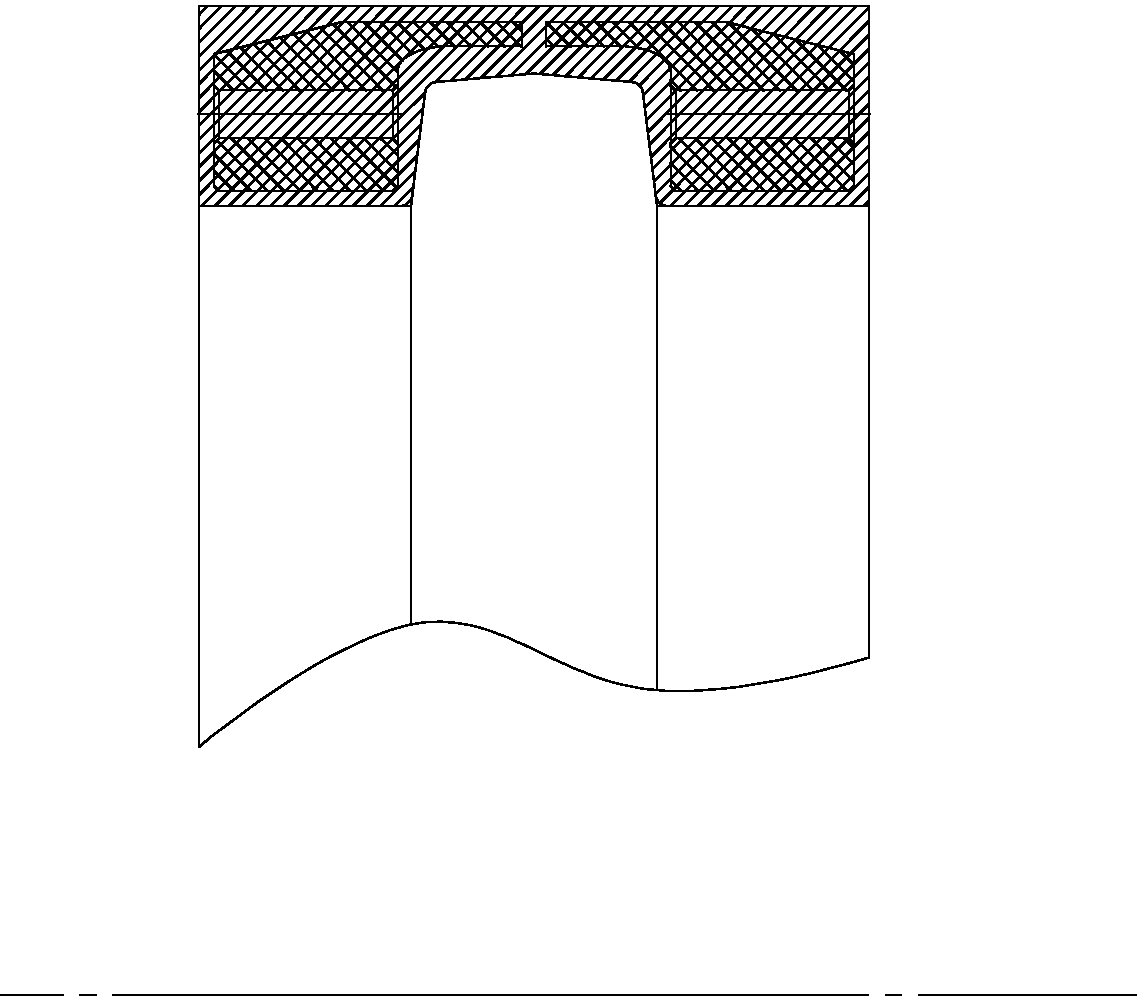

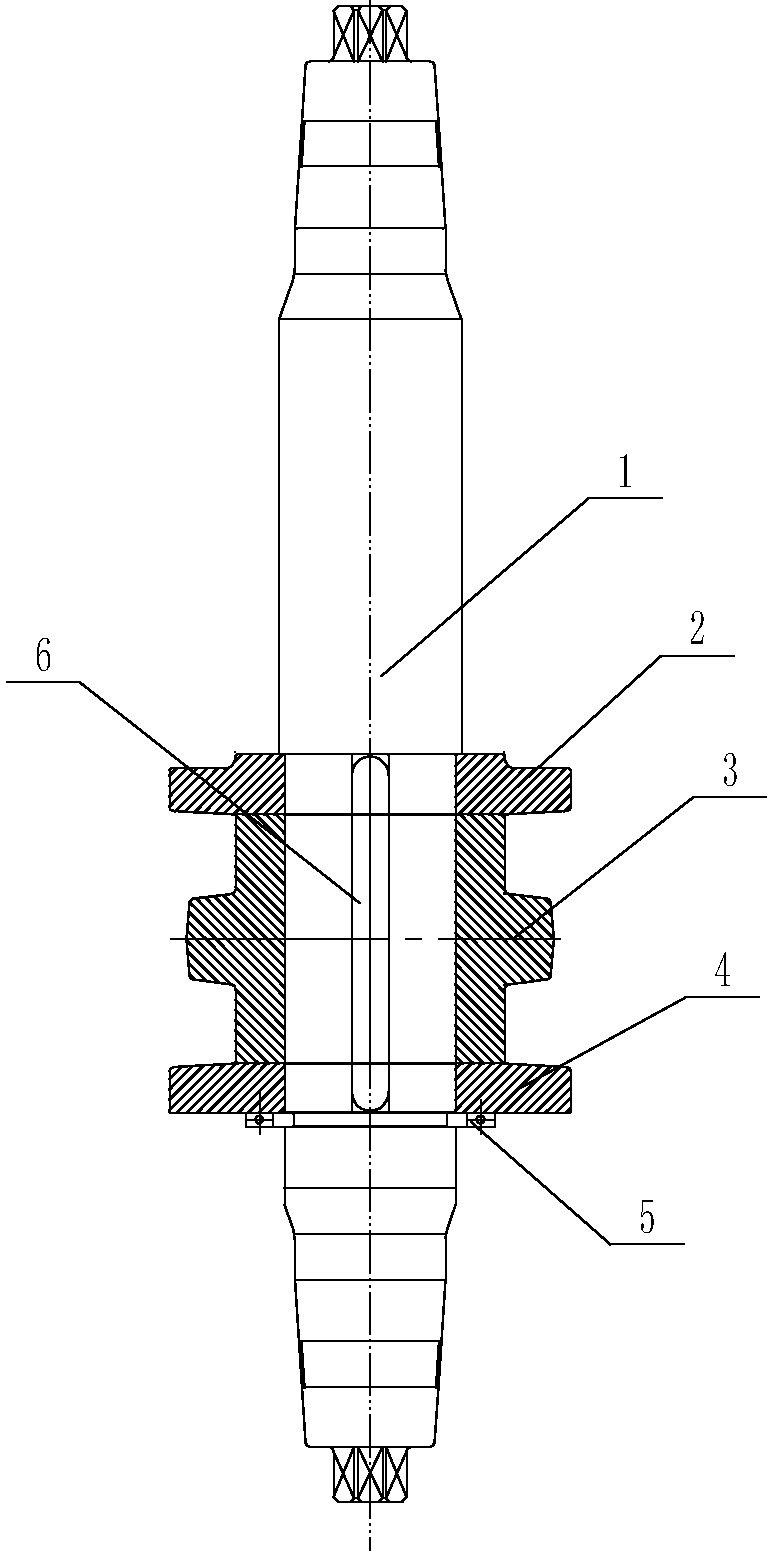

[0018] The manufacturing method of the special-shaped ring forging of the large wind tower flange, first of all, as figure 1 The ring forging shown is simulated in the ring rolling and rolling process to determine the optimum outer diameter of the forging blank when the first fire diameter is rolled in an axial rectangular section, guide the design of the ring rolling process, and then carry out actual production. Including the following process steps:

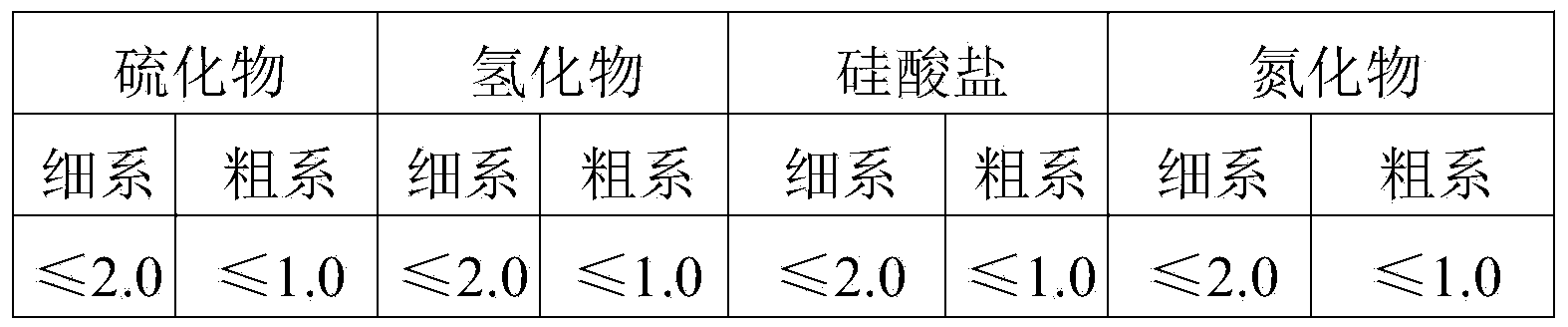

[0019] a) Take the billet steel—a continuous casting round billet ingot such as φ600 as the raw material, and the non-metallic inclusions in the billet steel meet the requirements of the following table:

[0020]

[0021] Then cut according to production requirements.

[0022] b) Forging billet ring rolling process: first,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com