Asphalt concrete as well as preparation method and application thereof

A technology of asphalt concrete and asphalt, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of easy flow of terminals, many terminals, and inability to purify, so as to prevent further diffusion, wide purification range, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This example provides an asphalt concrete, which consists of the following raw materials in parts by weight: 83 kg of limestone, 6 kg of limestone powder, 2 kg of magnetite, 2 kg of pyrite, 2 kg of rectorite, and 5 kg of SBS modified asphalt.

[0033] The preparation method of above-mentioned asphalt concrete is as follows:

[0034] Grinding pyrite, rectorite, and magnetite into fine powders respectively, so that the fineness of pyrite, rectorite, and magnetite is controlled at 20 mesh to 2000 mesh, and set aside;

[0035] Weigh 83kg of limestone heated to the temperature range of 160℃~180℃, dry mix the limestone for 20~40s, preferably 30s, then add 5kg of SBS modified asphalt and wet mix for 80~100s, preferably 90s, and add 6kg of limestone powder at the same time Wet mixing with 2kg of magnetite, 2kg of pyrite, and 2kg of rectorite fine powder for 80-100s, preferably 90s, to prepare 100kg of asphalt concrete capable of purifying and adsorbing PM2.5 particles.

[0036...

Embodiment 2

[0039] This embodiment provides an asphalt concrete, which is composed of the following raw materials in parts by weight: 90 kg of limestone, 4 kg of limestone powder, 1 kg of magnetite, 1 kg of pyrite, 1 kg of rectorite, and 3 kg of SBS modified asphalt.

[0040] The preparation process of the asphalt concrete of this embodiment is the same as that of Embodiment 1.

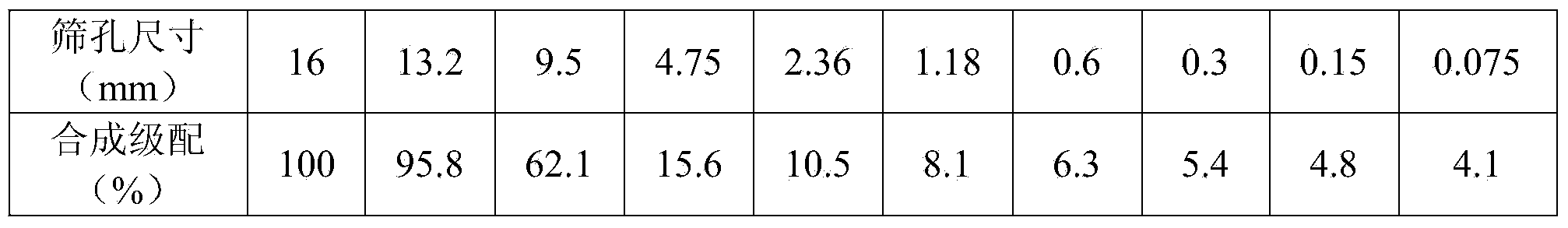

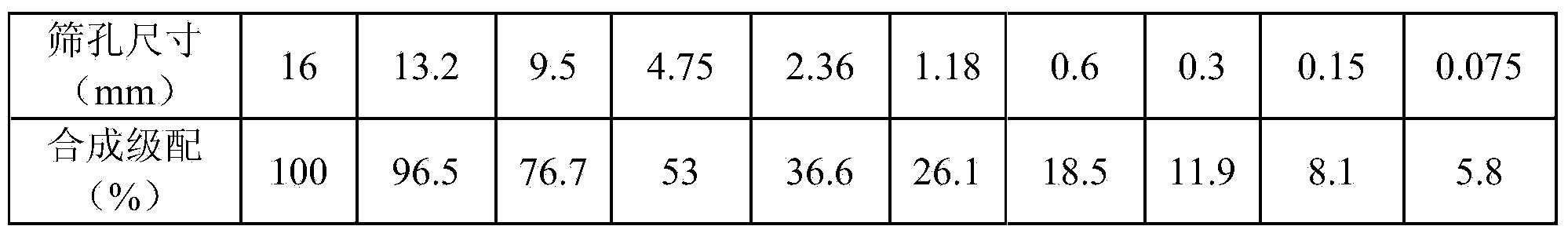

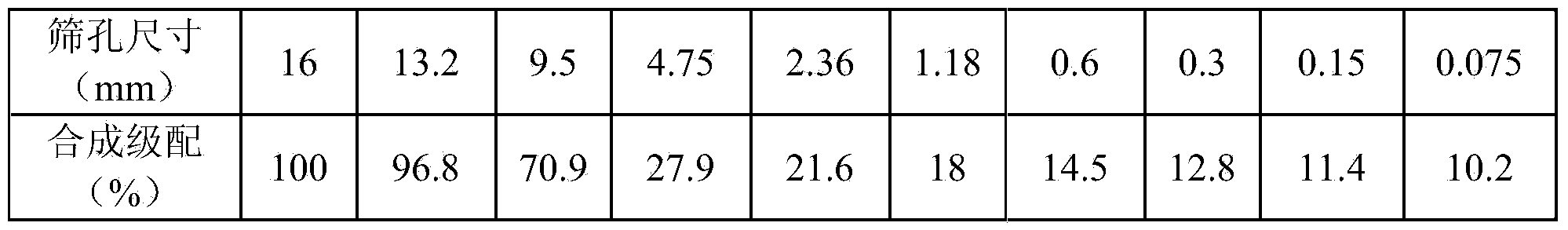

[0041] The asphalt concrete of this embodiment is used to pave the upper layer of the road according to the OGFC-13 gradation type, and the paving thickness is kept within the range of 3cm to 4cm, preferably 3.5cm, and the ordinary asphalt concrete construction method is used for paving. Can.

Embodiment 3

[0043] The present embodiment provides a kind of asphalt concrete, which is composed of the following raw materials in parts by weight: limestone 86.5kg, limestone powder 5kg, magnetite 1.5kg, pyrite 1.5kg, rectorite 1.5kg, SBS modified Bitumen 4kg.

[0044] The preparation process of the asphalt concrete of this embodiment is the same as that of Embodiment 1.

[0045] The asphalt concrete of this embodiment is used to pave the upper layer of the road according to the OGFC-13 gradation type, and the paving thickness is kept within the range of 3cm to 4cm, preferably 3.5cm, and the ordinary asphalt concrete construction method is used for paving. Can.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com