COB (Chip On Board) ceramic substrate preparation method and COB light source

A ceramic substrate and alumina ceramic technology, which is applied in the field of COB ceramic substrate preparation and COB light source, can solve the problems of low cutting efficiency, achieve low cost, avoid internal structure damage, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

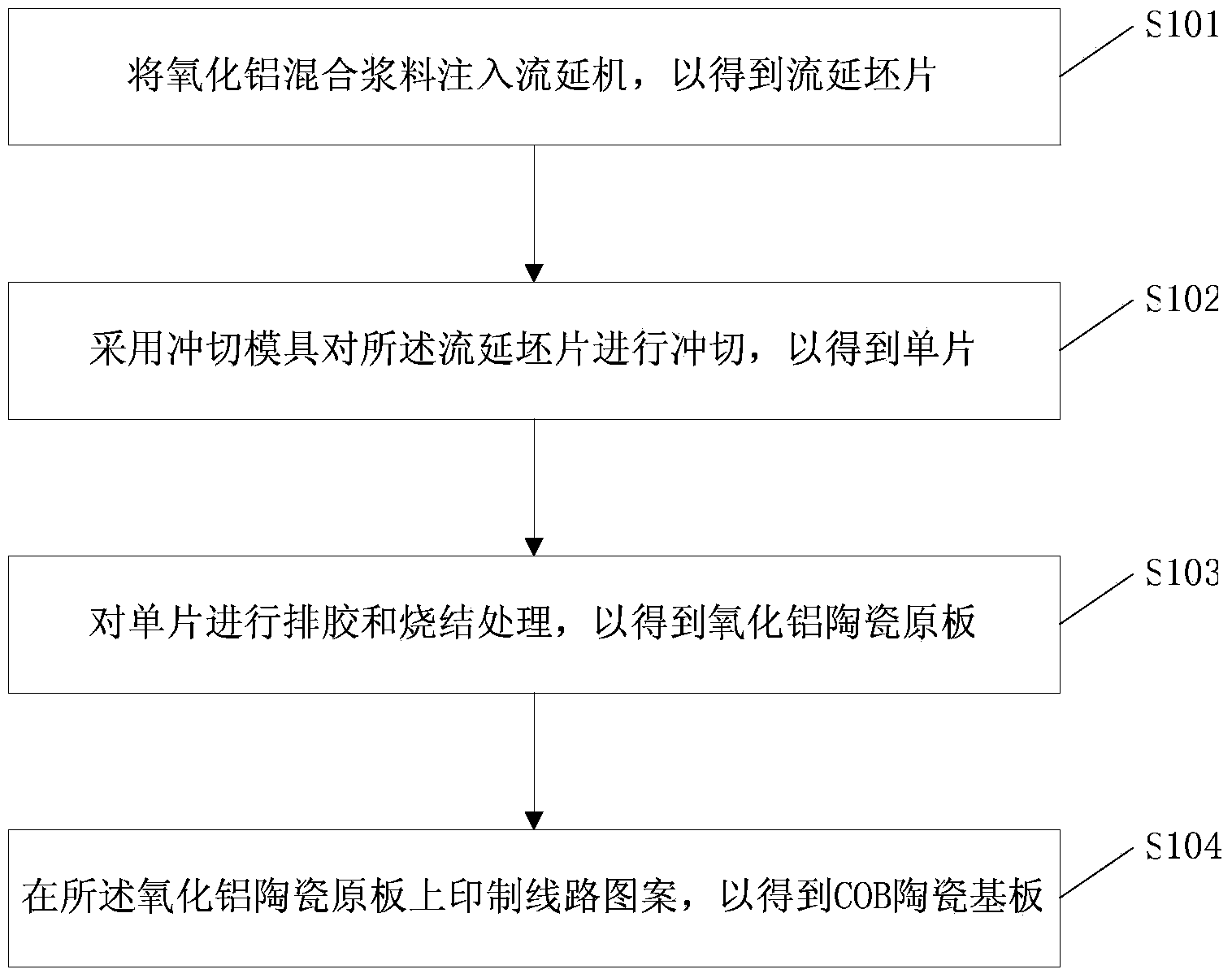

[0032] Such as figure 1 Shown, a kind of COB ceramic substrate preparation method, it comprises the following steps:

[0033] Step S101 , injecting the alumina mixed slurry into the casting machine, selecting an appropriate blade height and casting speed according to the required thickness of the substrate to obtain a cast green sheet, and then drying and stripping the cast green sheet.

[0034] Wherein, the preparation process of the alumina mixed slurry is:

[0035] Mix alumina powder with a purity greater than 98.6%, deionized water and dispersant in a ratio of 1:1:0.012 and ball mill for 36 hours to obtain a slurry. The slurry after mixing in this ratio has a moderate viscosity and is suitable for casting machines Casting; the dispersion agent of the present embodiment preferably adopts polyacrylic acid;

[0036] In order to ensure the best dispersion effect of polyacrylic acid and achieve the best stability of the slurry, it is necessary to add ammonia water to adjust t...

Embodiment 2

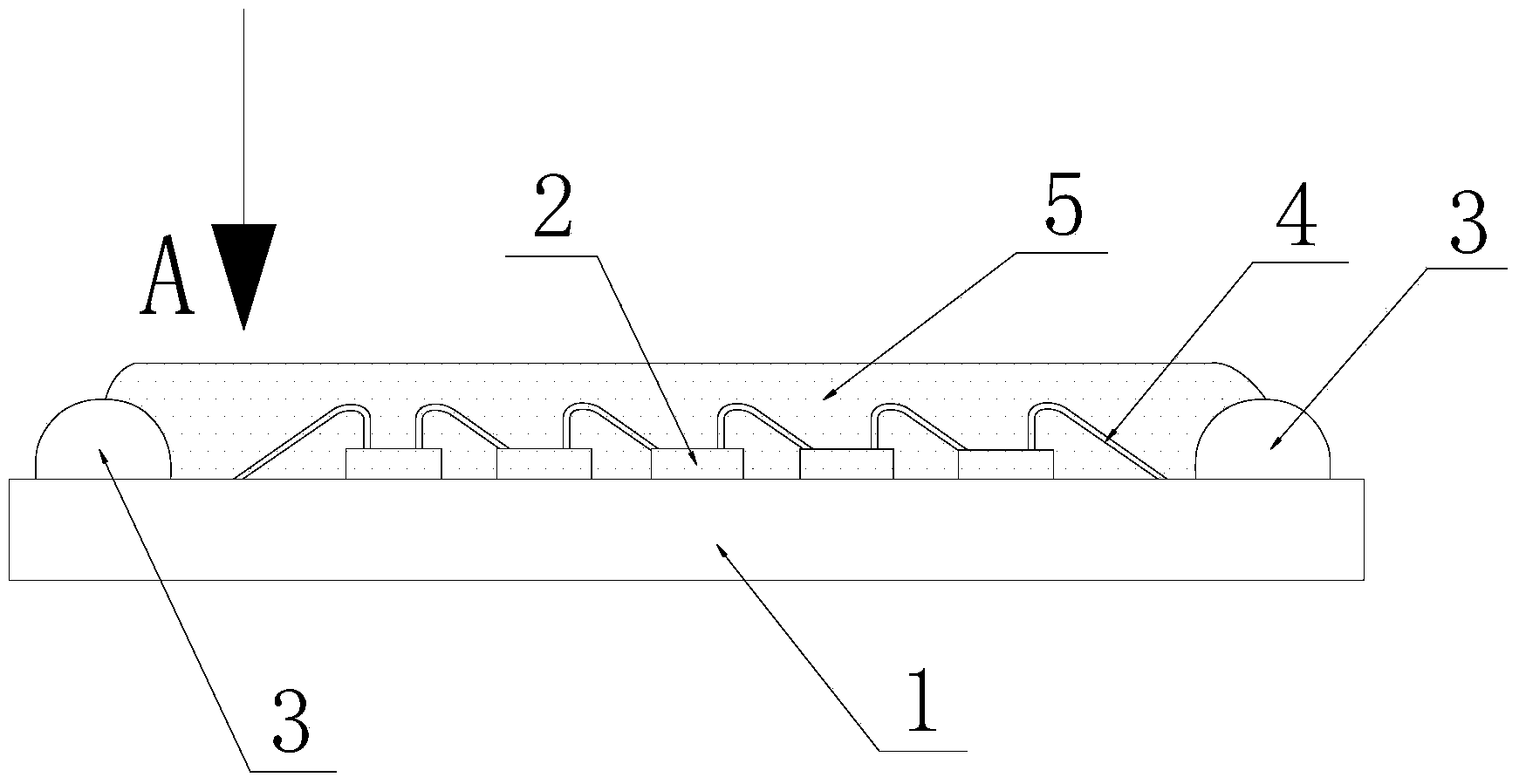

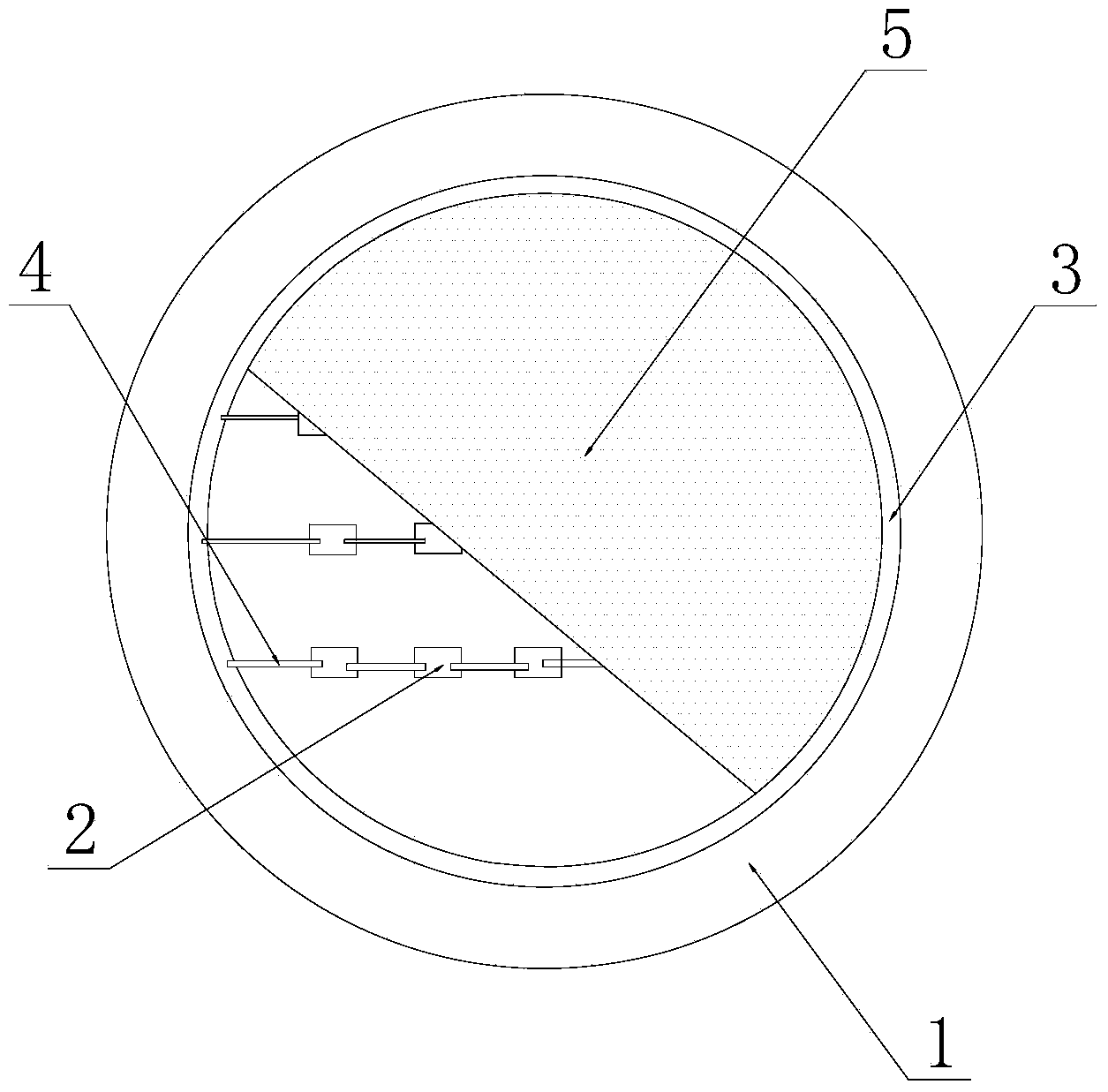

[0048] The difference between the present embodiment and the first embodiment lies in the step of punching the cast blank by using the punching die. Specific as Figure 4 shown.

[0049] A method for preparing a COB ceramic substrate, comprising the following steps:

[0050] Step S201, injecting the alumina mixed slurry into a casting machine to obtain a casting green sheet.

[0051] Step S202 , punching the casting green sheet by using a punching die to obtain continuous sheets. The connected sheet refers to a plurality of green sheets connected together.

[0052] combine Figure 5 and Figure 6 As shown, the V-cut pre-cutting process can be performed between the sheets in the continuous sheet, and the V-cut depth of the V-cut pre-cutting process is 70% of the thickness of the cast green sheet 100 . That is, a V-shaped crack is cut on the cast green sheet 100 to form a cutting line 10 with a cutting depth of 70% of its thickness. A plurality of separate COB ceramic sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com