Positive pressure, fully enclosed polygeneration gasifier

A fully enclosed, multi-generation technology, applied in fixed bed gasification, combustible gas production, petroleum industry, etc., can solve the problems of poor raw material adaptability, combustible gas leakage, uneven carbon production, etc., and achieve improved yield and collectability, maintenance rate reduction, and safety improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

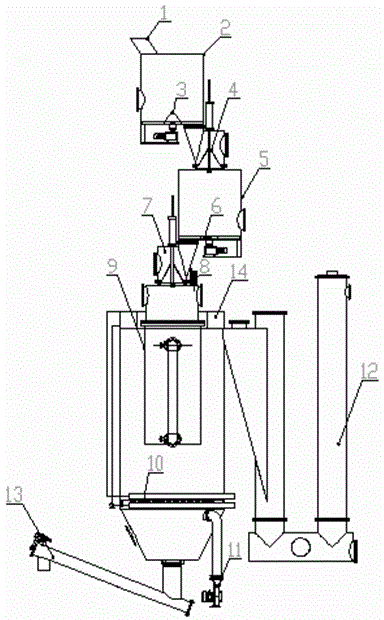

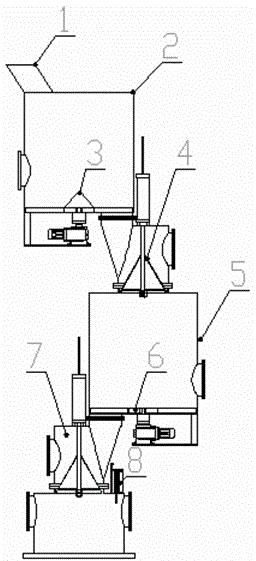

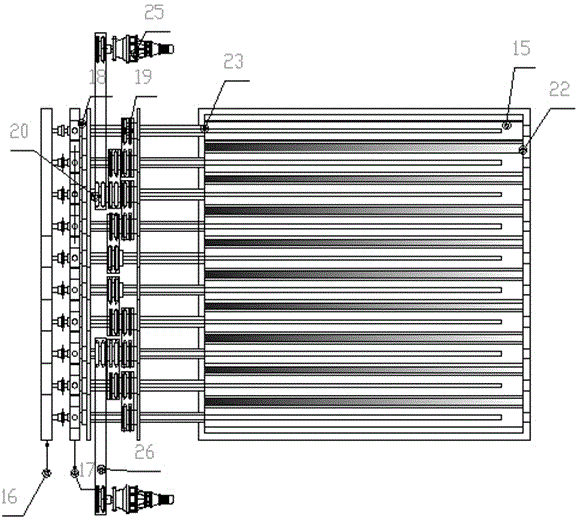

[0012] Positive pressure, fully-sealed multi-generation gasifier, its structure is equipped with a feed inlet, a main silo with internal stirring and an intermediate transition silo, two transition cone valve barrels, a water tank and a water tank on the top of the gasifier. Cooling system; the middle reaction chamber of the gasification furnace is provided with a feeding cylinder connected with the feeding part and extending into the lower part of the reaction chamber; the lower part of the reaction chamber of the gasification furnace is equipped with several externally driven toothed grates and a grate transmission system and an intermediate cooling water system; the upper part of the reaction chamber of the gasifier is provided with a gas outlet; the lower chamber of the gasifier is provided with a blower fan inlet; the bottom of the gasifier is provided with a charcoal discharge and cooling device.

[0013] Further illustrate technical solution of the present invention belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com