High temperature alloy for heat-resisting furnace roller and heat-resisting furnace roller for thermal treatment furnace

A high-temperature alloy and heat treatment furnace technology, which is applied in the field of heat-resistant alloy materials, can solve problems such as sticking steel and tumor accumulation, and achieve good thermal fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

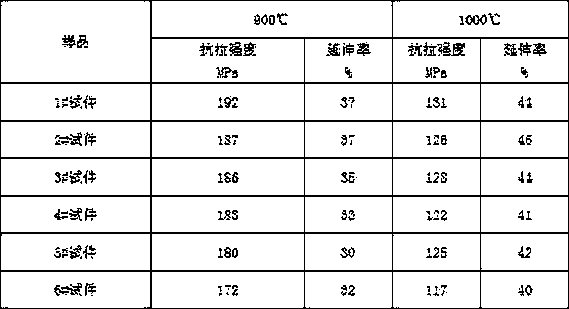

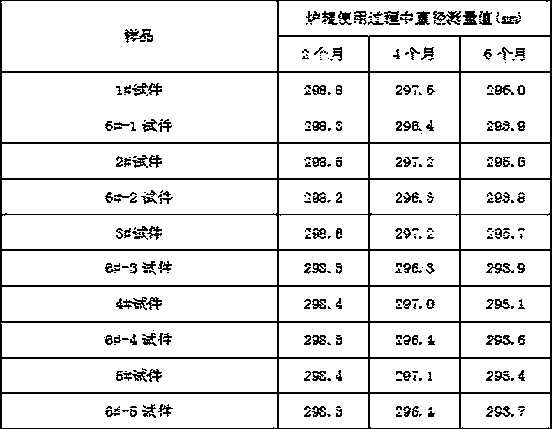

Embodiment 1

[0019] A heat-resistant furnace roll of a roller hearth heat treatment furnace, according to the chemical composition of the high-temperature alloy for the heat-resistant furnace roll designed in the present invention, it contains the following components in weight percentage: C 0.33%, Si 1.55%, Mn 0.85%, Cr 28.03 %, Ni36.98%, Co12.01%, W 3.24%, Mo 1.25%, Nb0.66%, Ce 0.08%, and the rest are Fe and impurities caused by manufacturing. The alloy material with the above ratio was smelted by the basic electric arc furnace non-oxidation method, and then the 1# test piece was obtained by centrifugal casting.

Embodiment 2

[0021] A heat-resistant furnace roll of a roller hearth heat treatment furnace, according to the chemical composition of the high-temperature alloy for the heat-resistant furnace roll designed in the present invention, it contains the following components in weight percentage: C 0.32%, Si 1.42%, Mn 1.08%, Cr27. 11%, Ni37.99%, Co11.10%, W3.48%, Mo1.50%, Nb0.41%, Ce 0.05%, and the rest are Fe and impurities caused by manufacturing. The alloy material with the above ratio was smelted by alkaline electric arc furnace non-oxidation method, and then the 2# test piece was obtained by centrifugal casting.

Embodiment 3

[0023] A heat-resistant furnace roll of a roller hearth heat treatment furnace, according to the chemical composition of the high-temperature alloy for the heat-resistant furnace roll designed in the present invention, it contains the following components in weight percentage: C 0.35%, Si 1.69%, Mn 0.80%, Cr28. 86%, Ni36.07%, Co12.79%, W2.51%, Mo1.02%, Nb0.90%, Ce 0.09%, the rest are Fe and impurities caused by manufacturing. The alloy material with the above ratio was smelted by the basic electric arc furnace non-oxidation method, and then the 3# test piece was obtained by centrifugal casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com