Soft magnetic target material

一种软磁性、靶材的技术,应用在磁性膜到基材的应用、磁记录、金属材料涂层工艺等方向,能够解决磁控管溅射、溅射不良、膜品质劣化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

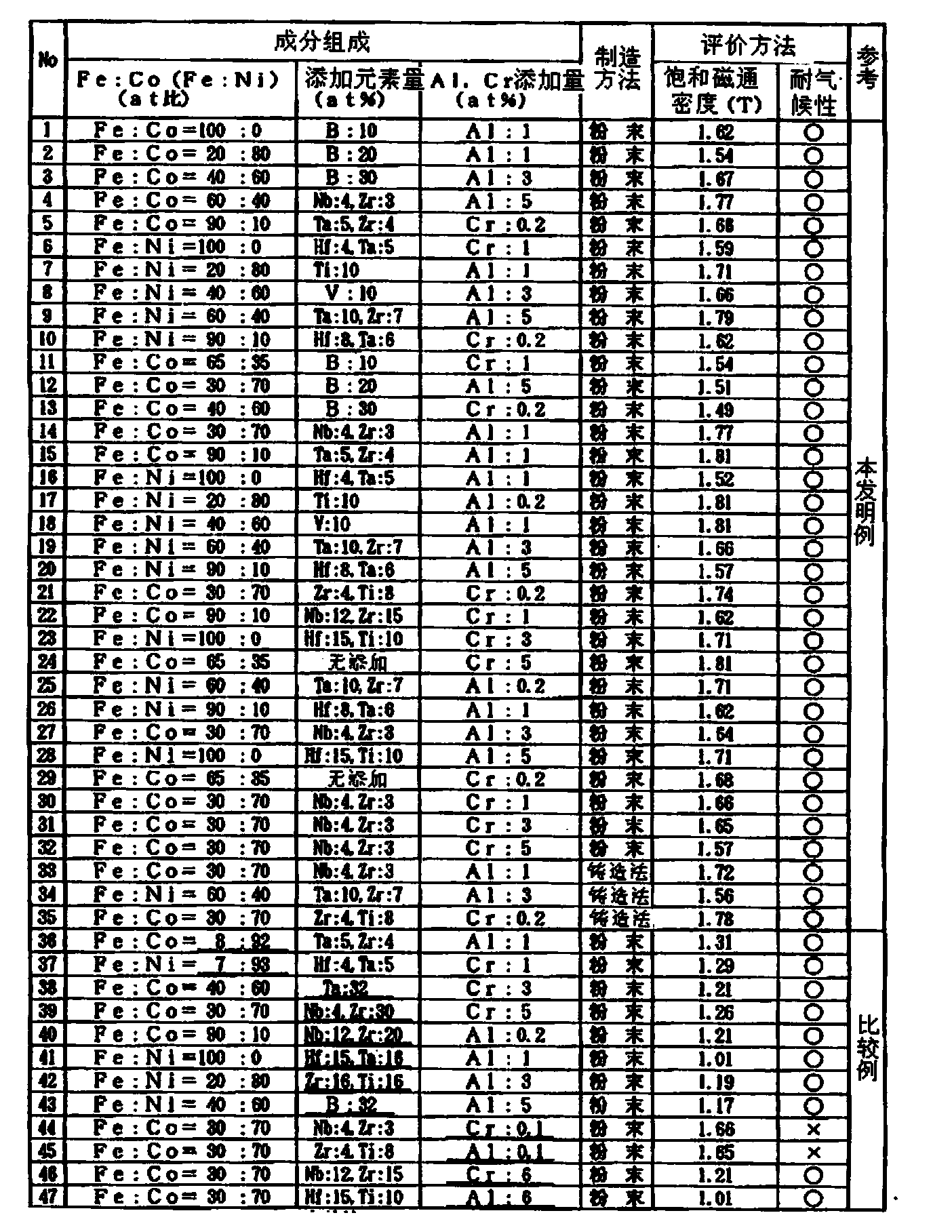

[0021] Hereinafter, the present invention will be specifically described by way of examples.

[0022] As shown in Table 1, Fe—Co-based alloys or Fe—Ni-based alloys were produced according to a gas-atomizing method or a casting method. The gas atomization method was carried out under the conditions that the gas type was argon, the diameter of the nozzle was 6 mm, and the air pressure was 5 MPa. On the other hand, the casting method is performed by melting in a ceramic crucible (ф200×30L) and then pulverizing to obtain powder. The powders thus produced were classified into 500 μm or less, and each powder was stirred for 1 hour with a V-type mixer.

[0023] Each powder produced in this way is filled into a sealing can made of SC material with a diameter of 200 mm and a height of 100 mm, and after reaching a vacuum degree of 10-1Pa or more, degassing and vacuum sealing is performed, and then HIP (Hot Isostatic Pressing) , under the conditions of temperature 1173K, pressure 150MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com