Connection structure and construction method of friction damper assembled frame joints

A technology for connecting structures and dampers, which is used in building components, building structures, and earthquake resistance, can solve problems such as low seismic energy consumption, and achieve the effects of consuming seismic energy, saving costs, and having broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

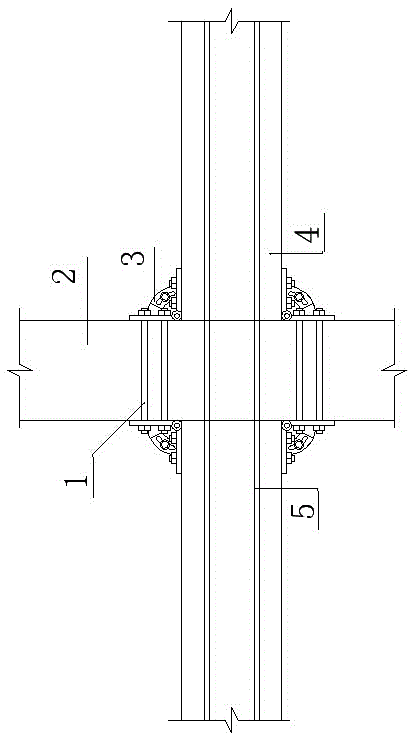

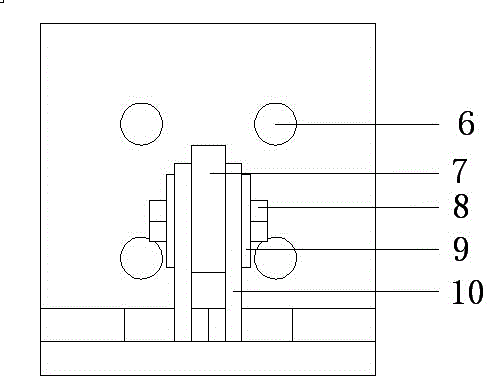

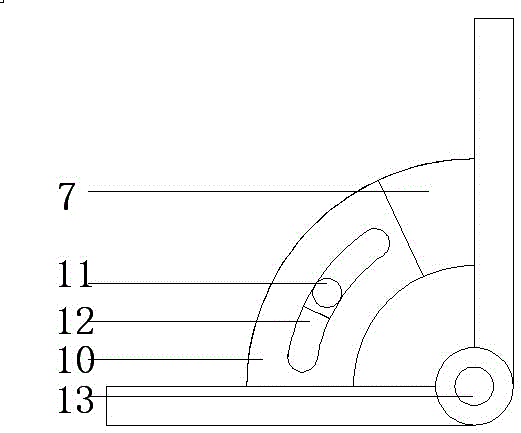

[0028] The invention discloses a connection structure of an assembled frame node of a friction damper and a construction method thereof. The idea of the invention is to install friction dampers 3 at joints between prefabricated reinforced concrete columns 2 and prefabricated reinforced concrete beams 4 to form an integral connection structure of prestressed additional friction damper assembled frame joints. This design ensures that the prefabricated concrete frame structure realizes the effective connection of nodes and effective energy consumption when an earthquake occurs.

[0029] specific structure See attached Figure 1-8 , This prestressed additional friction damper assembled frame structure node connection structure is composed of three parts: prefabricated reinforced concrete column 2 , prefabricated reinforced concrete beam 4 and friction damper 3 . For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com