Keel components and construction methods used in in-situ foam concrete for filling walls in the building insulation reverse method

A technology of foam concrete and building insulation, applied in building components, buildings, building structures, etc., can solve the problems of easy generation of construction waste, large block production equipment, cumbersome construction technology, etc., and achieve fast cast-in-place speed and short construction period , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

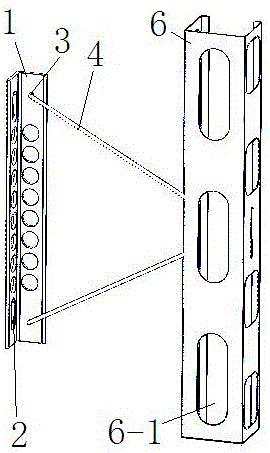

[0061] Keel components used in cast-in-place foam concrete for infill walls in building insulation inversion

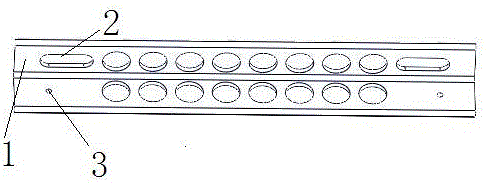

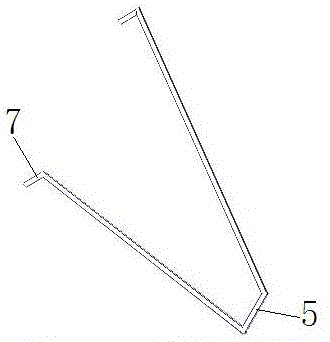

[0062] refer to Figure 1-5 . The keel assembly includes an "L"-shaped connecting angle iron 1 that is fixedly connected to a thermal insulation prefabricated panel. A "V"-shaped support frame 4 is installed under the connecting angle iron 1, and one side of the support frame 4 is installed on a "C"-shaped main keel. 6, connect the angle iron 1, the support frame 4 and the main keel 6 to form a keel frame; the side plate connecting the angle iron 1 is provided with a hole 2 matching the riveting hole on the heat preservation prefabricated plate, and the bottom plate is provided with a mounting The support hole 3 of the support frame 4, the hook 7 of the support frame 4 is installed in the support hole 3, the beam 5 of the support frame 4 is installed in the beam hole 6-3 of the main keel 6; on the front of the "C" type main keel 6 There is a rectangular hole 6-1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com