Movable reaction equipment for shield launching shaft

A technology of counterforce equipment and originating shafts, which is applied in mining equipment, earthwork drilling, tunnels, etc., and can solve the problems of high steel pipe diameter and welding requirements, increased construction cost, construction difficulty, and increased construction cost. Problems such as the construction period, to achieve the effect of low pipe diameter requirements, shortened construction period, and low construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

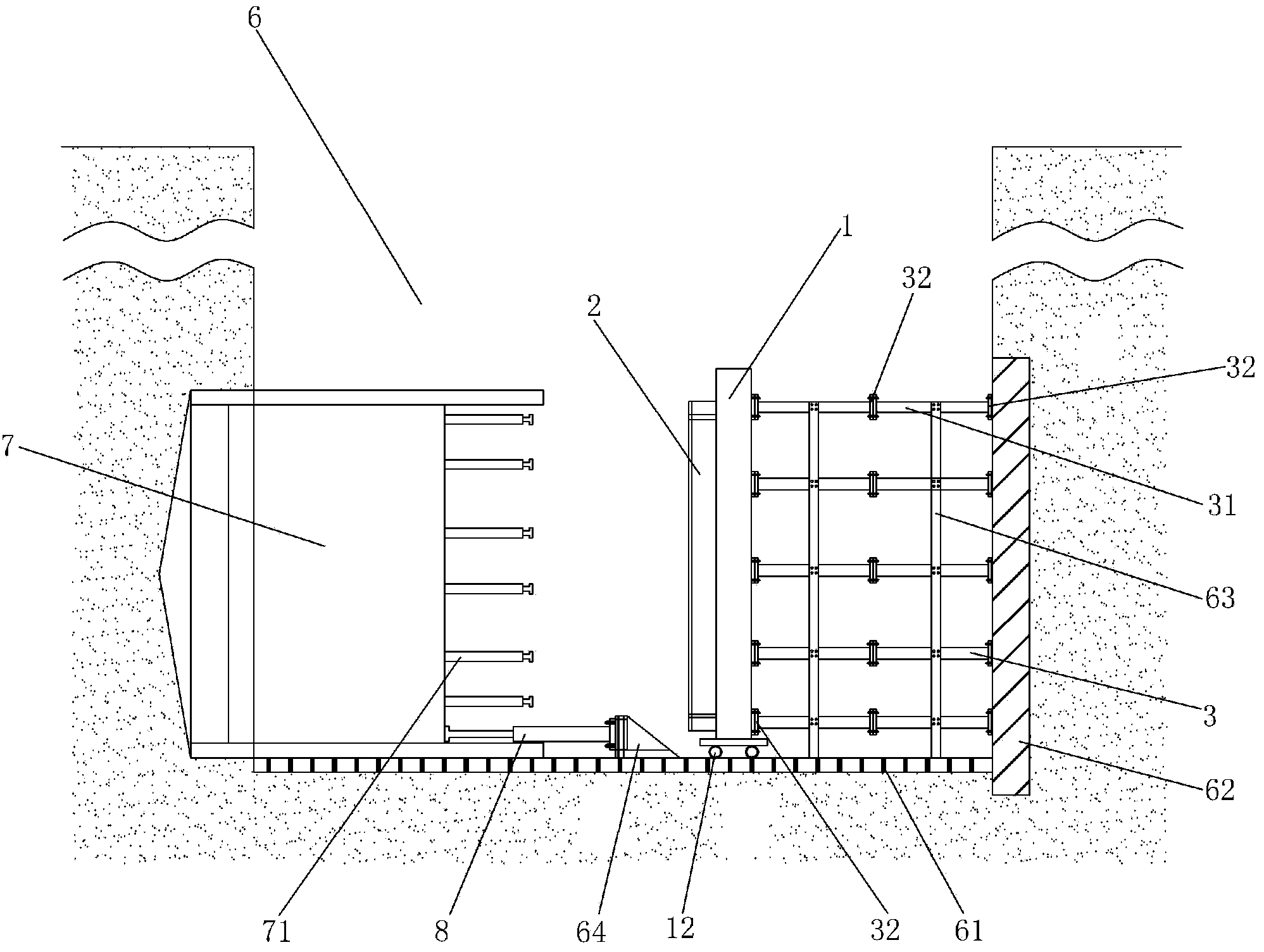

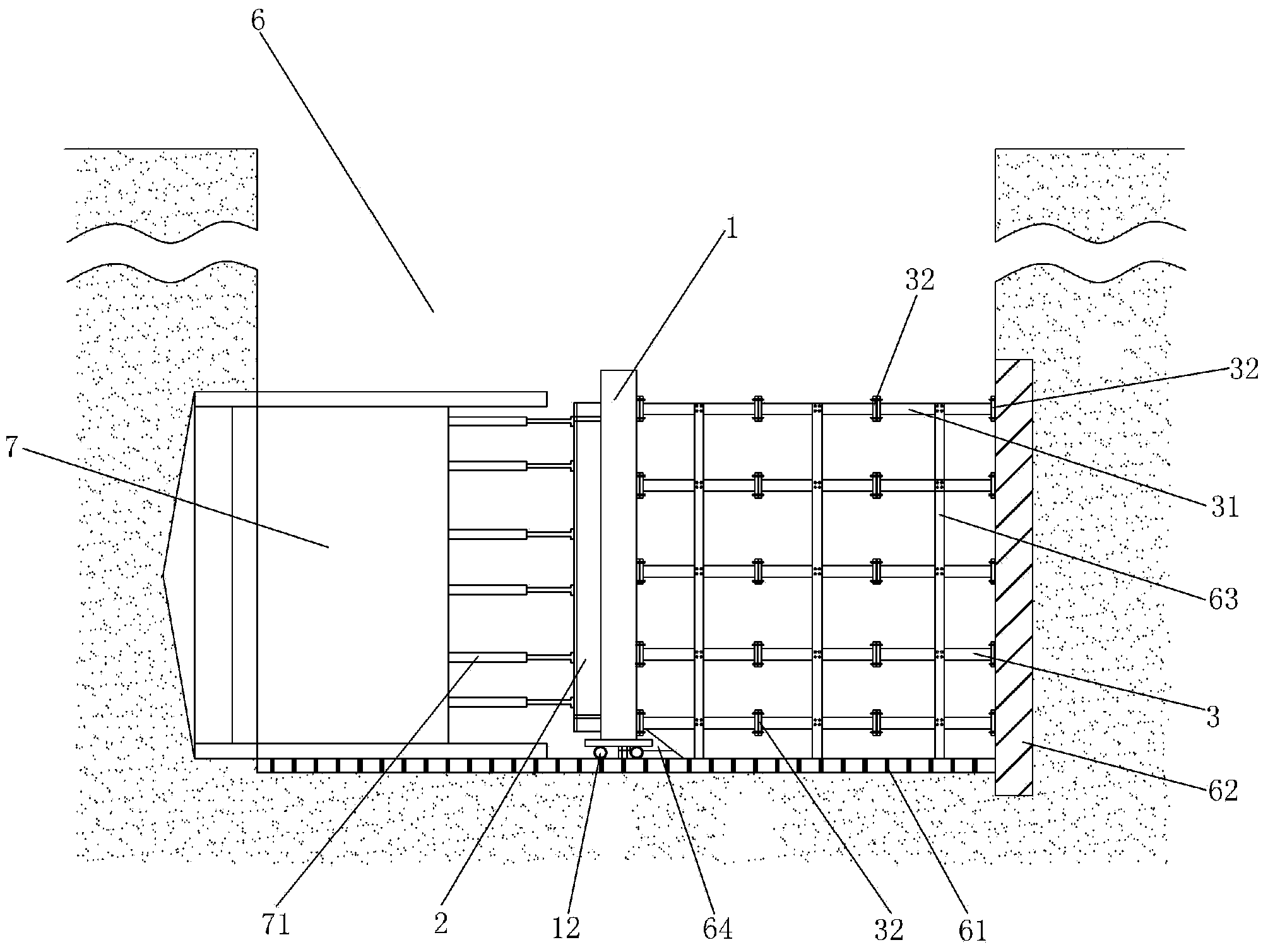

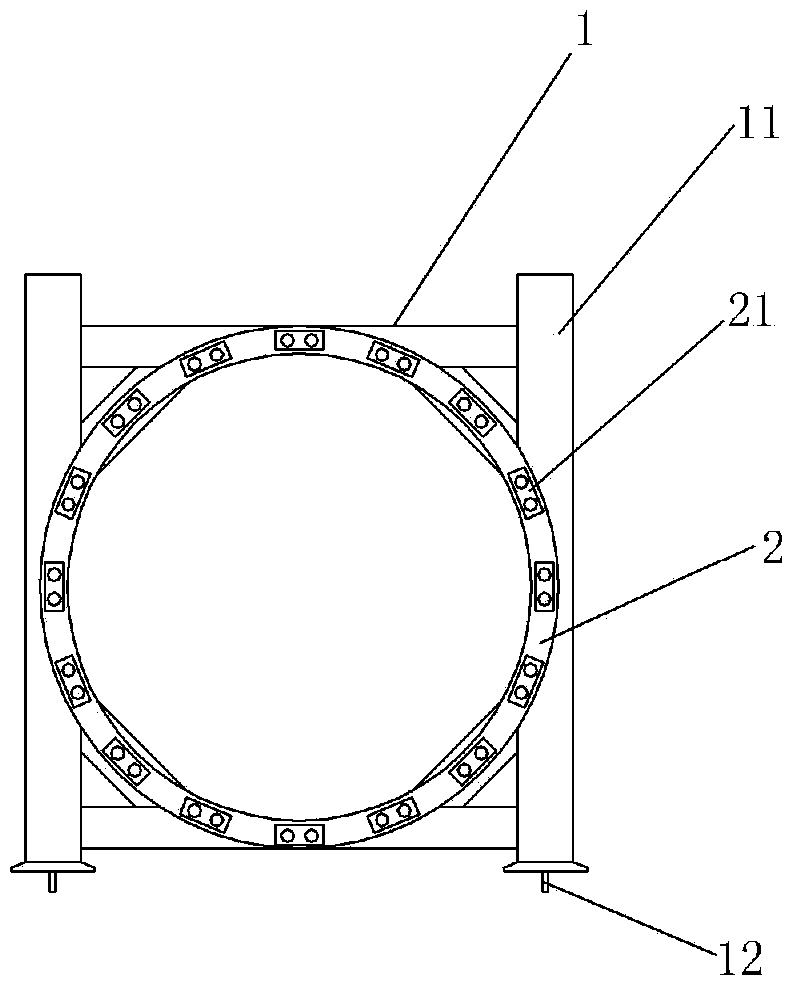

[0034] Figure 1-3 It is shown that a specific embodiment of the present invention is a movable counter force device for a shield launching shaft. On the track 61 of the bracket, the reference steel ring 2 welded to the front of the main beam 1 is characterized in that: the back of the main beam 1 is connected to the flange 32 at the front end of the horizontal support pipe 3, and the rear end of the horizontal support pipe 3 The flange 32 is close to the push-back wall 62 of the shield tunneling shaft, and the horizontal support pipe 3 is a single steel pipe 31 or more than two steel pipes 31 connected by the flange 32. The steel pipe 31 The length of the length is less than the stroke of the jack 71 of the shield machine 7;

[0035] The horizontal support pipe 3 of this example is 32-12. The steamboat 12 matching the track 61 of the starting bracket is installed at the lower end of the column 11 . The front side of the reference steel ring 2 is provided with a jack groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com