Inflow Chamber For Catalytic Converter Of Emission Control System

An exhaust gas purification and catalytic converter technology, which is applied in gas chambers, exhaust gas treatment, exhaust devices, etc., can solve the problems of unsatisfactory mixing of the exhaust gas to be purified and the reducing agent, and achieve good orientation and homogeneity. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

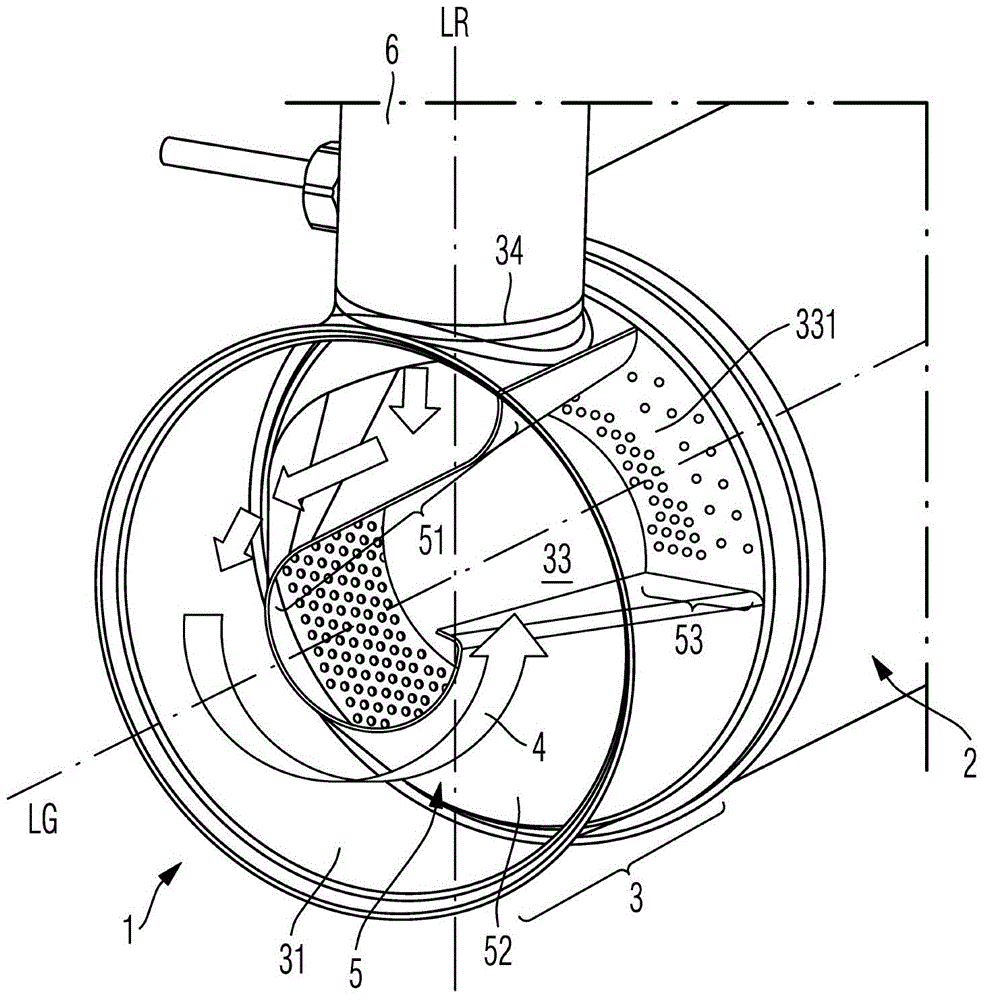

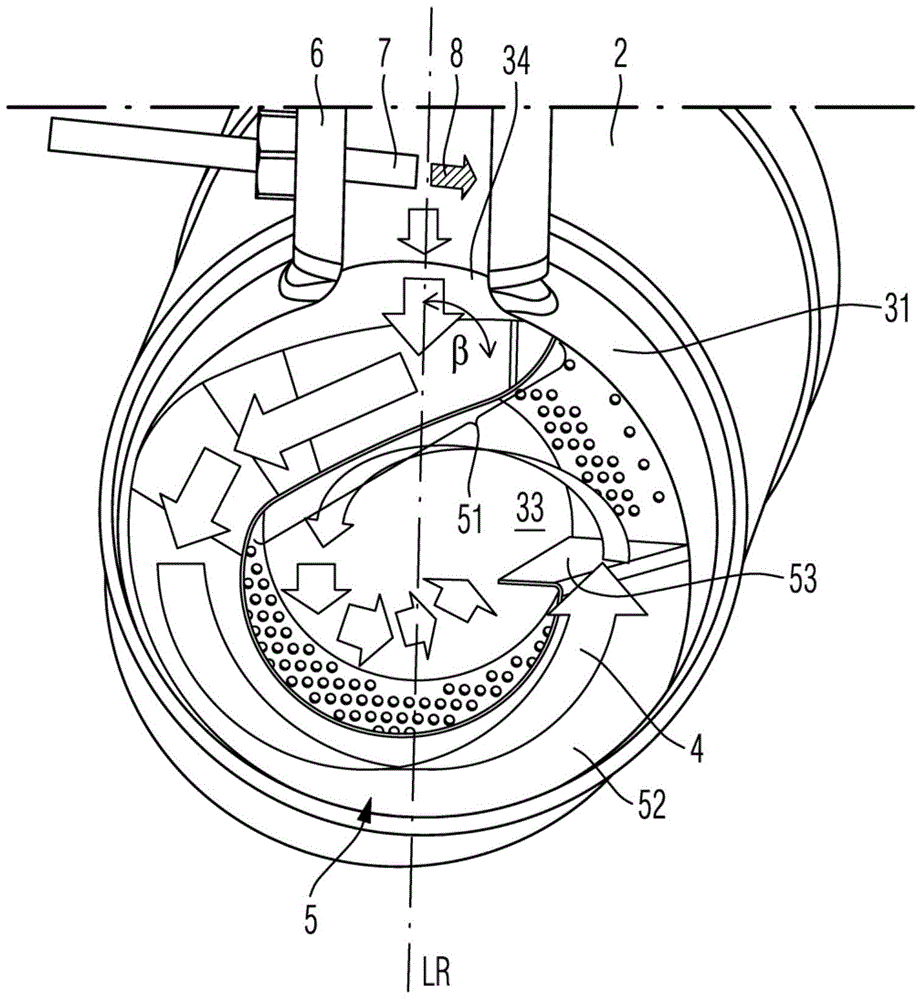

[0063] Refer below Figures 1 to 6 An embodiment of an inflow chamber 1 for an exhaust gas catalytic converter 2 is described, which can be used, for example, in Figure 7 In the motor vehicle exhaust purification system 9 shown in.

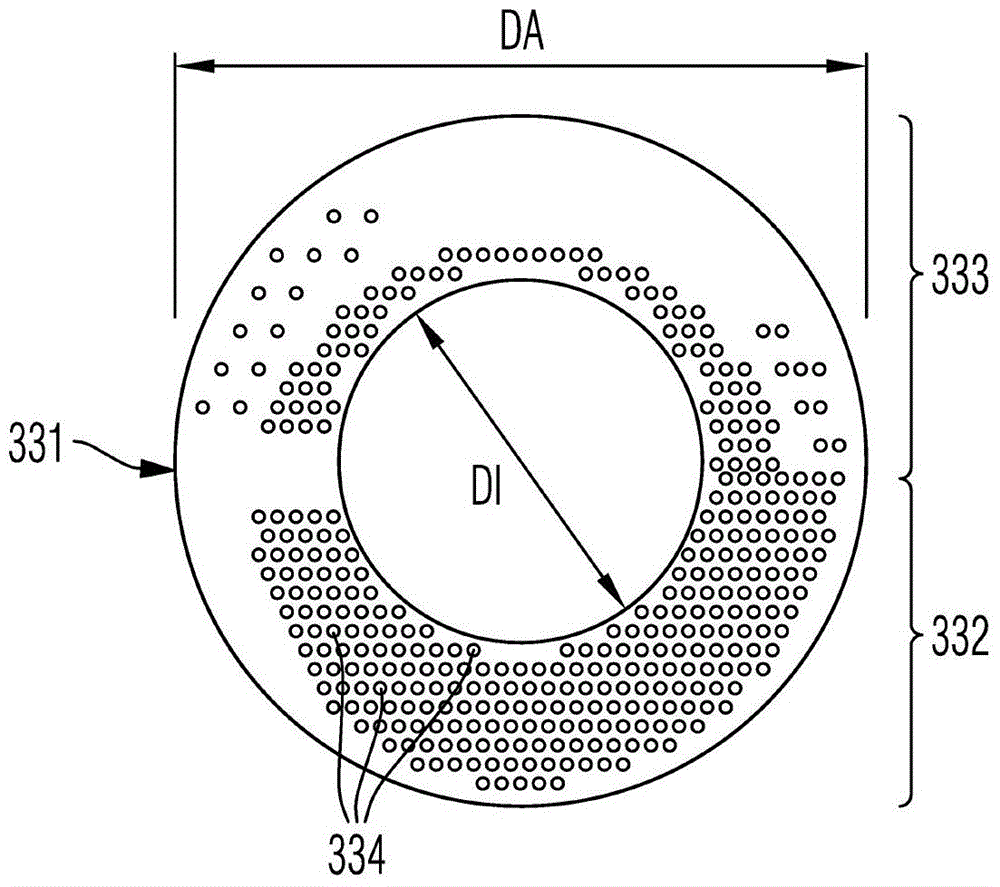

[0064] The inflow chamber 1 has a substantially cylindrical housing 3 with a peripheral surface 31 and two end surfaces 32 , 33 . exist figure 1The peripheral surface 31 facing the viewer and not shown in the middle and the first end surface 32 are made of stainless steel and are welded to each other in a gas-tight manner. In the embodiment shown, the first end face 32 is a covering cap which is also gas-tight like the peripheral face 31 itself of the cylindrical housing 3 . The second end face 33 , which is spaced apart from the first end face 32 along the longitudinal axis LG of the cylindrical housing 3 , has, in the embodiment shown, a ring 331 made of stainless steel which is likewise gas-tight on its outer edge. The ground is welded tog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com