Machine vision based LED detection device and detection method thereof

A machine vision and detection device technology, applied in the direction of testing optical performance, etc., can solve the problems of not suitable for mass application in production lines, not supporting simultaneous detection of multiple LEDs, low detection efficiency, etc., achieving low cost, improved stability, and cost savings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

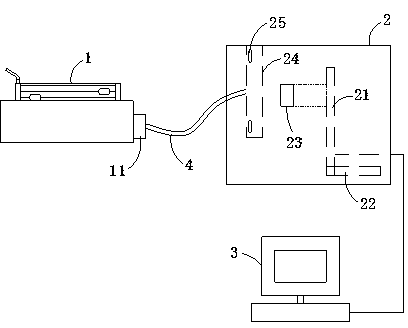

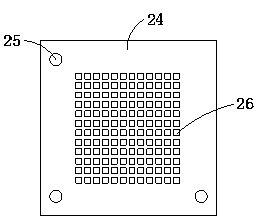

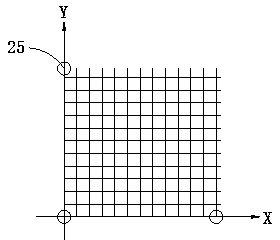

[0039] Such as Figure 1 to Figure 3 Shown is an embodiment of the machine vision-based LED inspection device of the present invention. Such as figure 1 , figure 2 As shown, the LED detection device includes a carrier board fixture 1 for placing the LED to be tested, a dark box 2, and an industrial computer 3. The dark box 2 is provided with an industrial camera 21 connected to the industrial computer 3. The industrial camera 21 is arranged on the dark box 2. The camera bracket 22 inside is fixedly supported, the industrial camera 21 is provided with a fixed-focus lens 23, and the camera obscura 2 is also provided with a light-condensing plate 24 arranged at the front end of the fixed-focus lens 23, and three positioning lights with different colors are arranged on the plane of the light-condensing plate 24. 25 , a through hole 26 is set in the plane of the coordinate system formed by the positioning light 25 , and the carrier fixture 1 is connected to the through hole 26 t...

Embodiment 2

[0045] The present invention is the embodiment that adopts the detection method of above-mentioned LED detection device based on machine vision, comprises the following steps:

[0046] S1. The LED to be tested lights up and emits light, and the LED light is transmitted to the light collecting plate in the dark box through the conductive fiber;

[0047] S2. The industrial camera collects the original image on the condensing plate and transmits it to the industrial computer through the Gigabit network card;

[0048] S3. The industrial computer preprocesses the collected original image, and first recognizes three color positioning lights with red, green and blue colors respectively;

[0049] S4. The industrial computer calculates the region of interest after obtaining the positioning light, and maps this area to the original image, and further recognizes the position coordinates of the three colored positioning lights through the principle of three primary colors; after the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com