Transportable reformer

A reformer, reformer tube technology, applied in the field of reformers, can solve the problems of time-consuming, delay in the completion of the factory, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A fully assembled reformer can be shipped as a unit. The reaction chamber, which basically comprises the reformer tube system and the combustion device, is only shown here in a simplified manner.

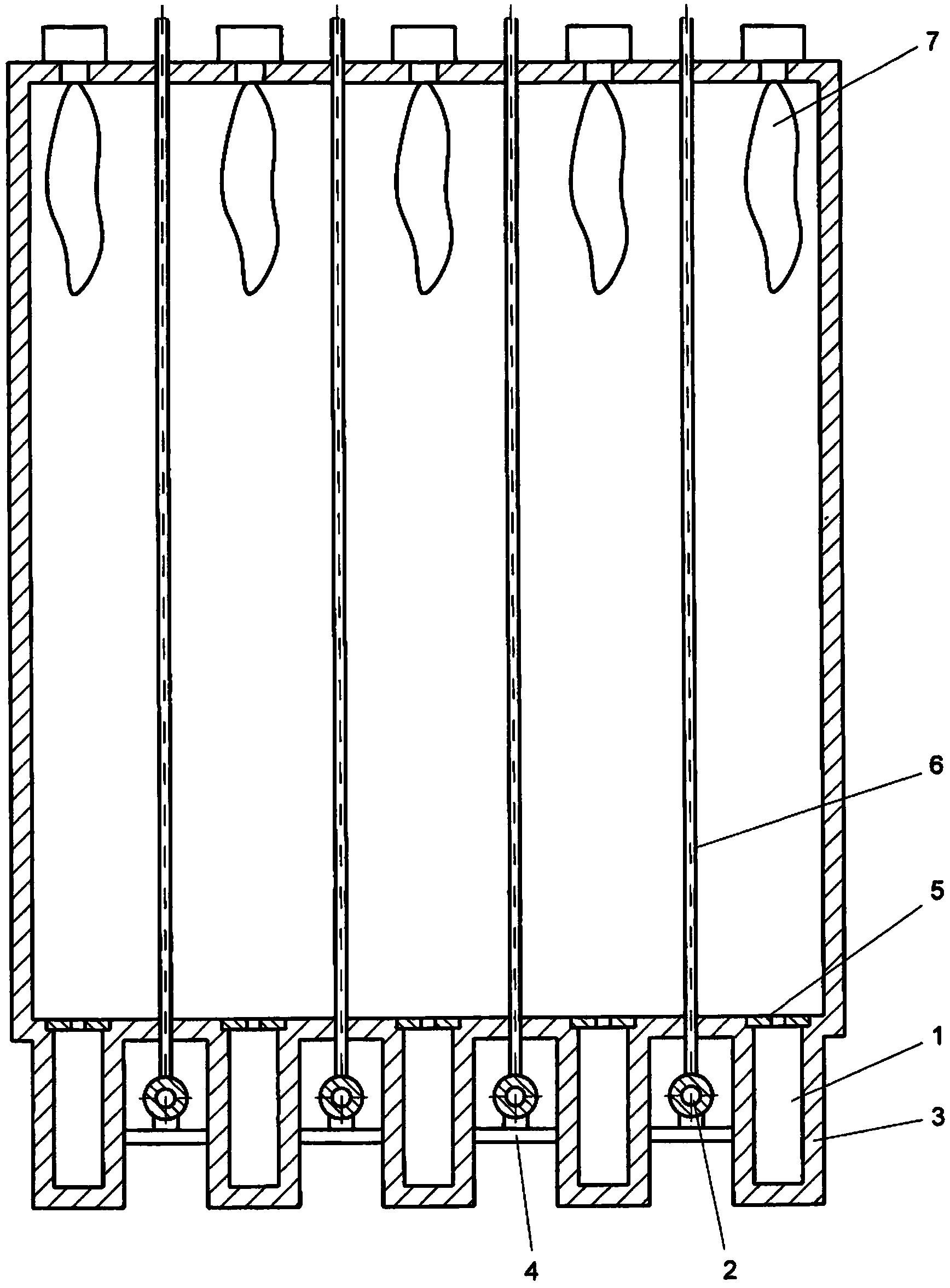

[0036] figure 1 Shown are a plurality of flue gas channels (1) arranged in parallel in the horizontal direction below the combustion zone and manifolds (2), said flue gas channels (1) being positioned between each manifold (2). The depth of the flue gas channel can be 2m to 3m, preferably 2.5m, the width of the flue gas channel is 0.5m to 0.8m, and the refractory lining (3) of the flue gas channel (1) is about 0.2m to 0.35m. The diameter of the manifold (2) including the refractory lining is 0.5 to 0.66 meters.

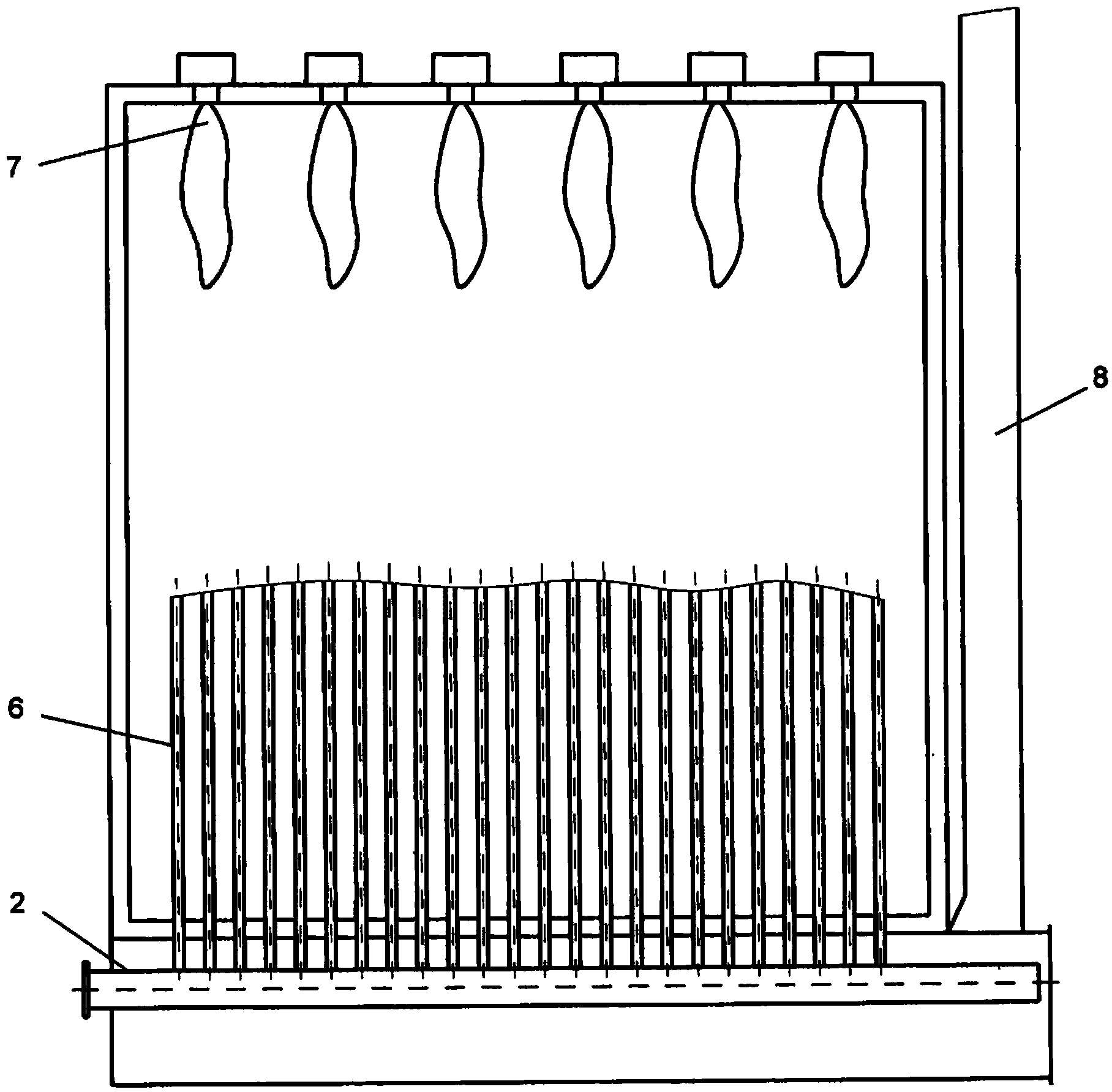

[0037] In addition to the burner (7), process gas pipe (6) and manifold (2), figure 2 Also shown is the warm air stack (8) enabling a constant supply of fresh air between the manifolds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com