Method for producing cohesive polyacrylate adhesive compounds with a narrow molar mass distribution

A technology of acrylate and polymer, applied in the field of molecular weight of polyacrylate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

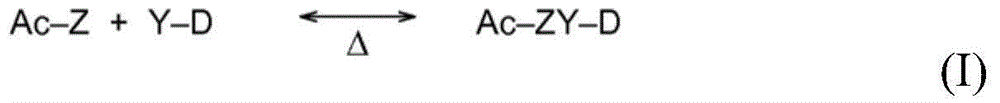

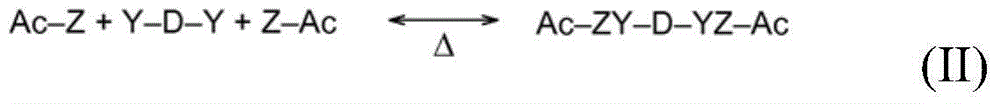

Method used

Image

Examples

Embodiment

[0142]

[0143] The following test methods were used in order to evaluate the process adhesion properties and general properties of the prepared PSAs.

[0144] ESI-MS measurement (test A)

[0145] Mass spectra were recorded on an LXQ mass spectrometer (ThermoFisher Scientific, San Jose, CA, USA) equipped with an atmospheric pressure ionization source in nebulizer-assisted electrospray mode. The instrument was calibrated in the range 195-1822 m / z using standard volumes of caffeine, Met-Arg-Phe-Ala acetate (MRFA), and a mixture of fluorinated phosphazenes (Ultramark 1621) (all from Sigma-Aldrich) . A constant spray voltage of 3.5 kV and a dimensionless purge gas flow rate of 8 and a carrier gas flow rate of 2 were set. Capillary voltage, lens voltage, and capillary temperature were 60V, 120V, and 275°C.

[0146] Gel Permeation Chromatography GPC (Test B)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com