Mixing equipment for high pressure natural gas and low pressure coal gas and mixing method

A technology of mixing equipment and natural gas, applied in the direction of gas and gas/vapor mixing, mixing methods, mixers, etc., to achieve the effect of improving energy bottlenecks and solving pressure fluctuation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

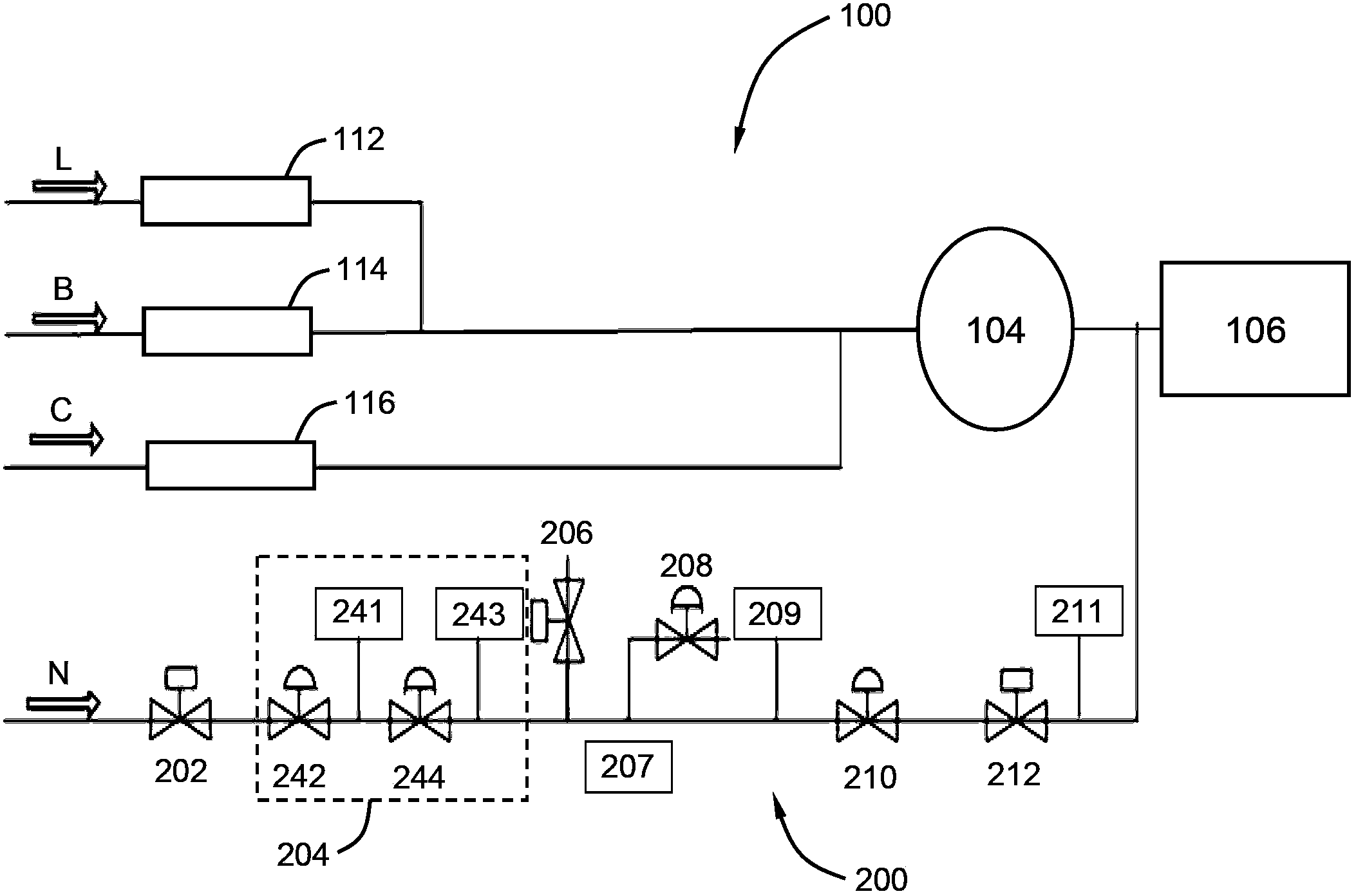

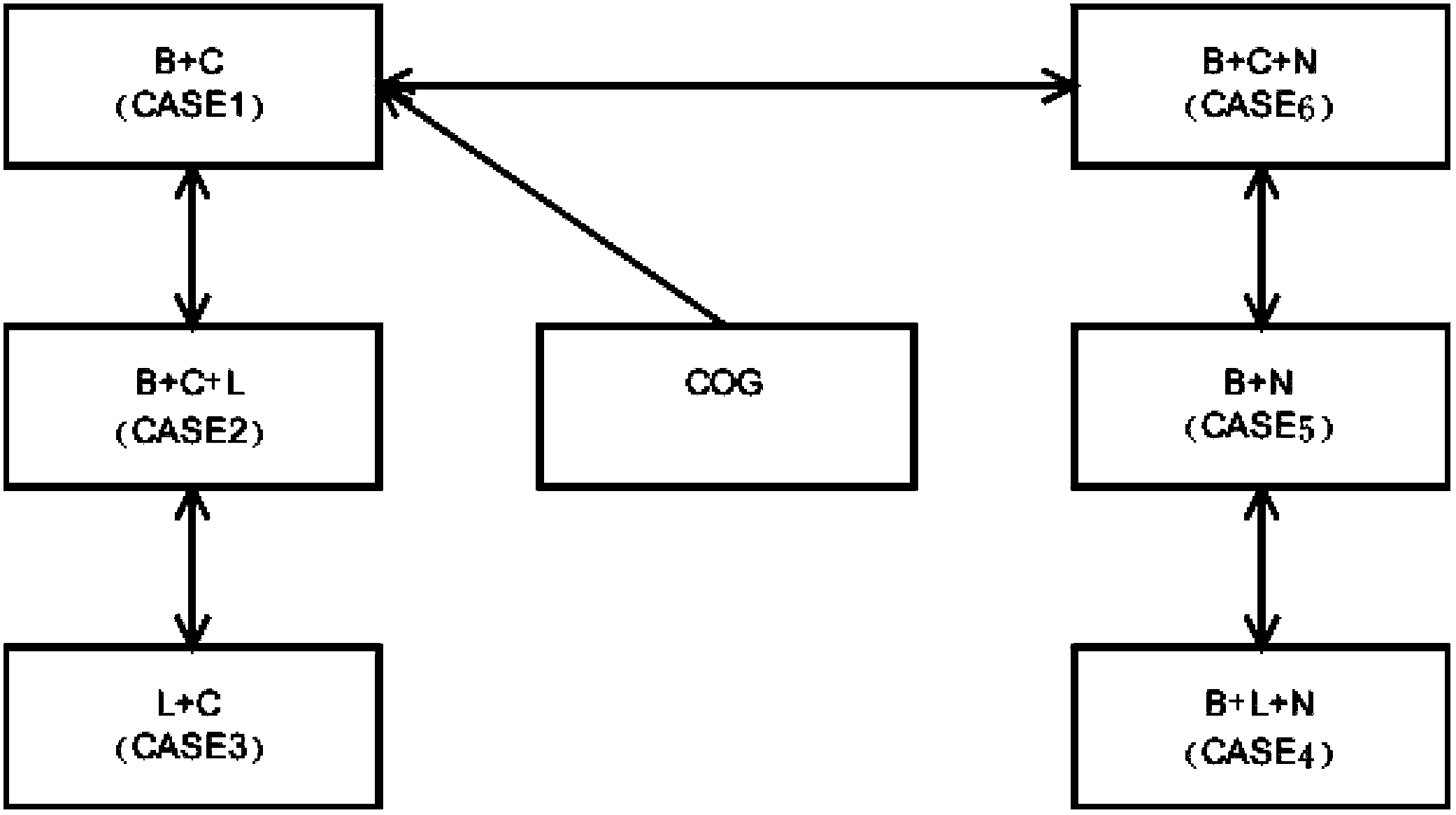

[0030] The most commonly used state is CASE2, that is, the mixed mode of coke oven gas + blast furnace gas + converter gas. When natural gas needs to be put into operation, it is first necessary to switch the mixed mode from CASE2 to CASE1: coke oven gas + blast furnace gas, waiting for a steady state Finally, switch the mixed mode from CASE1 to CASE6 coke oven gas + blast furnace gas + natural gas, so that natural gas is put in. After considering the equipment configuration, it is necessary to design the control scheme, including each interlock, valve opening and closing sequence, opening degree and control mode, etc. First of all, before switching the mixing mode, it must be ensured that the valves on the involved pipelines must be in the "automatic" mode, to ensure that all valves have no alarms, no faults and normal actions, and that all flow and pressure detection equipment are in good working condition. The important condition is to set the lower limit of the total amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com