High-frequency quenching device for right-angle part of rotary body

A technology of high-frequency quenching and rotary body, which is applied in the field of heat treatment, can solve the problems of difficult heating, obvious sharp corner effect, and difficulty in meeting the technical requirements of the quenching part of parts, and achieve the effect of increasing the heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Describe the present invention below in conjunction with specific embodiment:

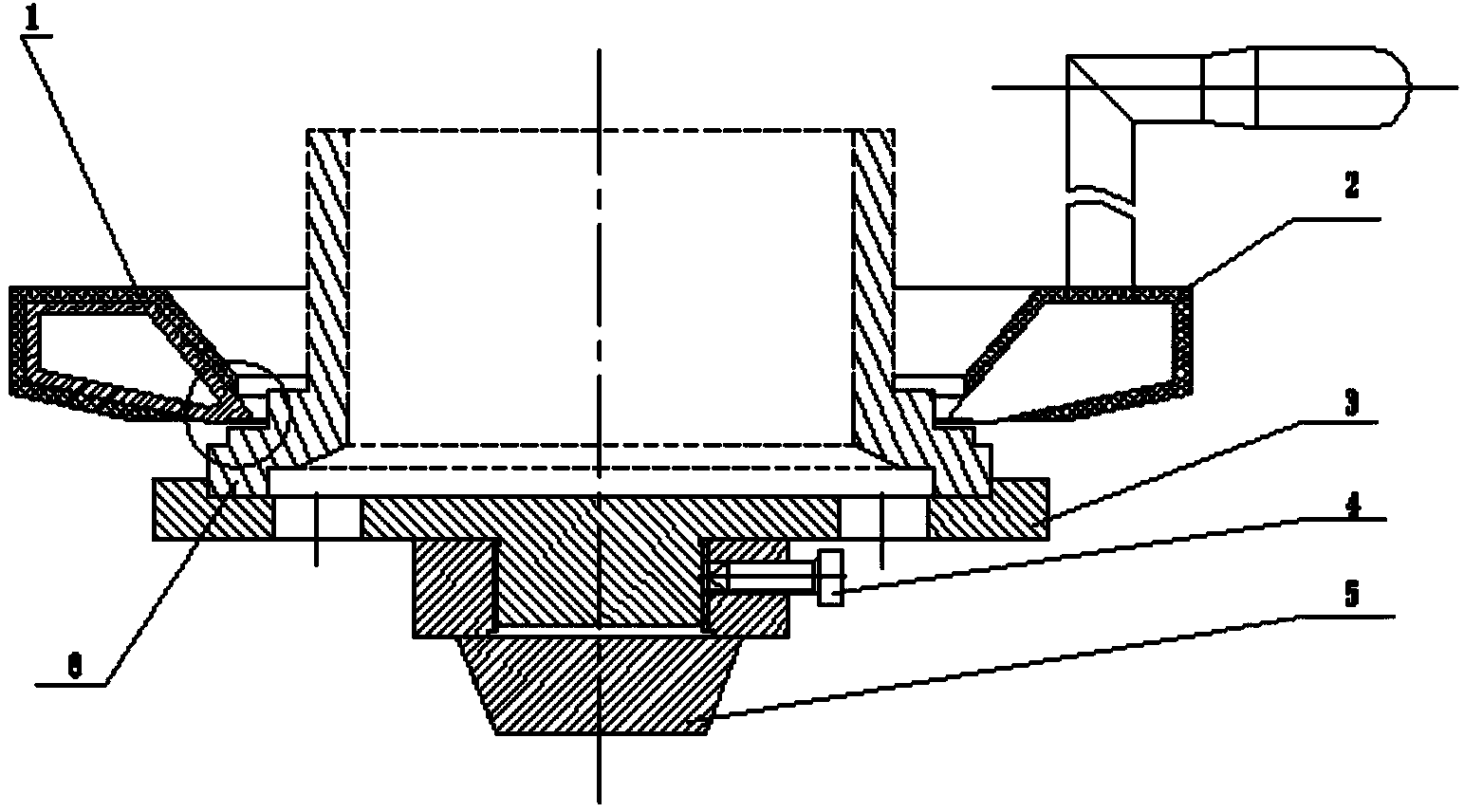

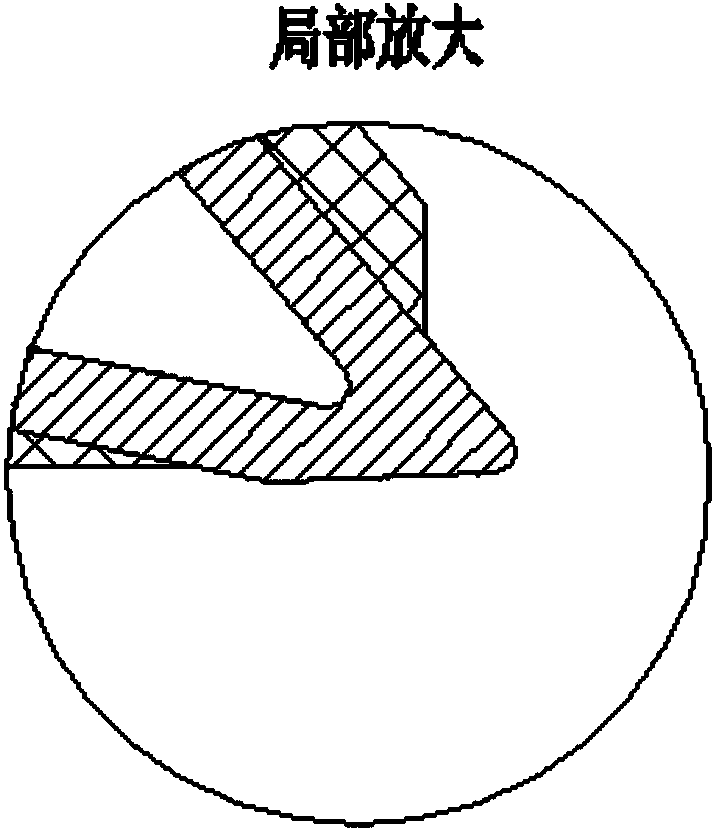

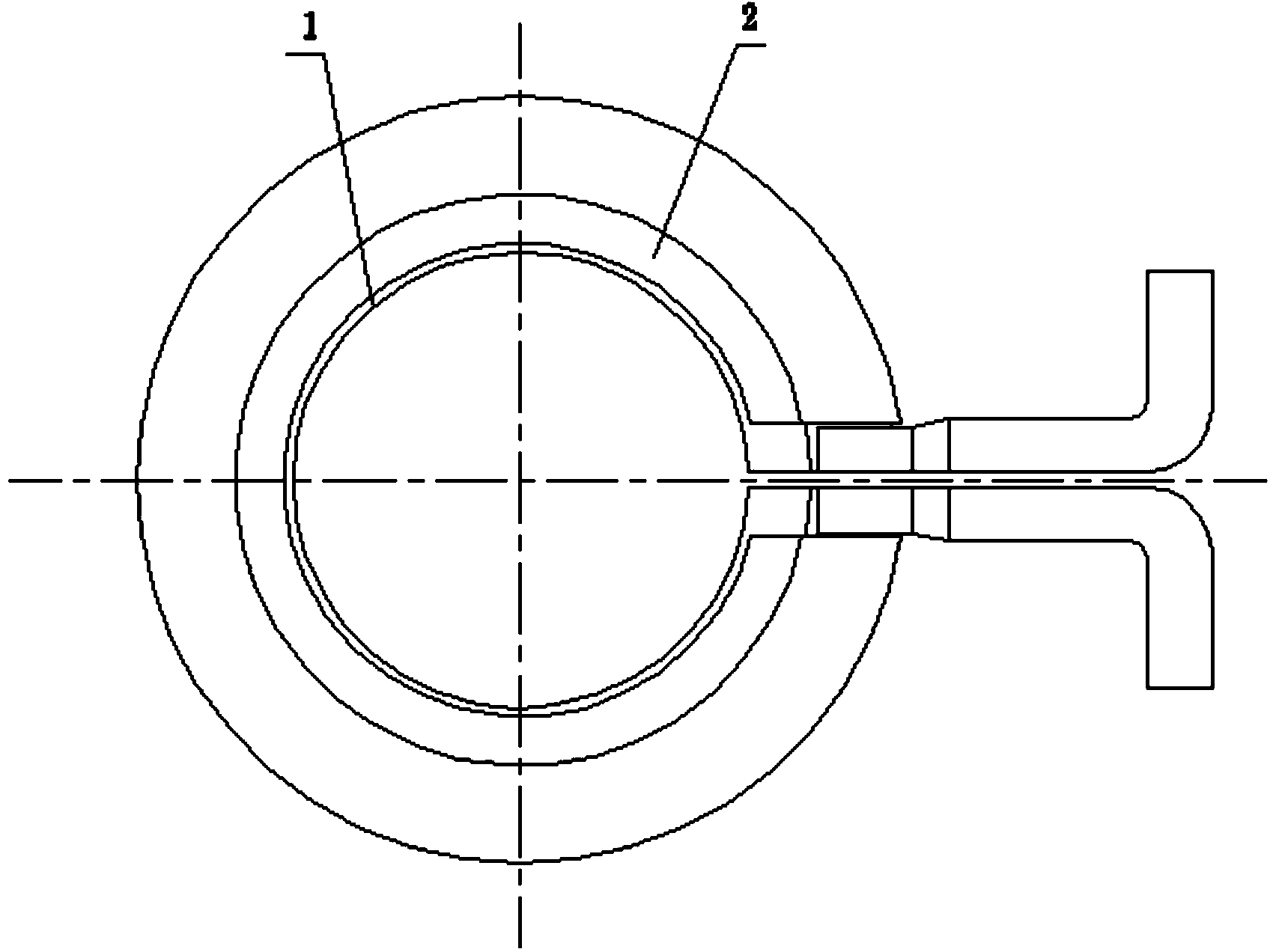

[0023] according to figure 1 As shown, in this embodiment, a device for high-frequency quenching at right-angle parts of a rotating body includes an induction coil 1 , a magnetic conductor 2 , a tray 3 , a screw stopper 4 , and a connecting column 5 .

[0024] The pallet is used to support the rotary part 6 to be processed, the pallet 3 is a rotary structure, the upper end is provided with a step for placing the part 6, and the lower end is provided with a connecting thread. The connecting column 5 is a body of revolution, the upper end is provided with a connecting threaded hole 5-1, the side wall of the connecting threaded hole is provided with a threaded small hole 5-2, and the lower end is provided with a taper handle 5-3 connected with the main shaft of the machine tool. The screw stop 4 is a threaded body of revolution. When in use, the part 6 is placed in the step at the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com