Gear type rotary engine

A rotary engine and gear type technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of high weight, complex engine structure, small effective arm, etc., and achieve high energy conversion efficiency, easy and fast. Start and stop, reduce the effect of eccentric vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

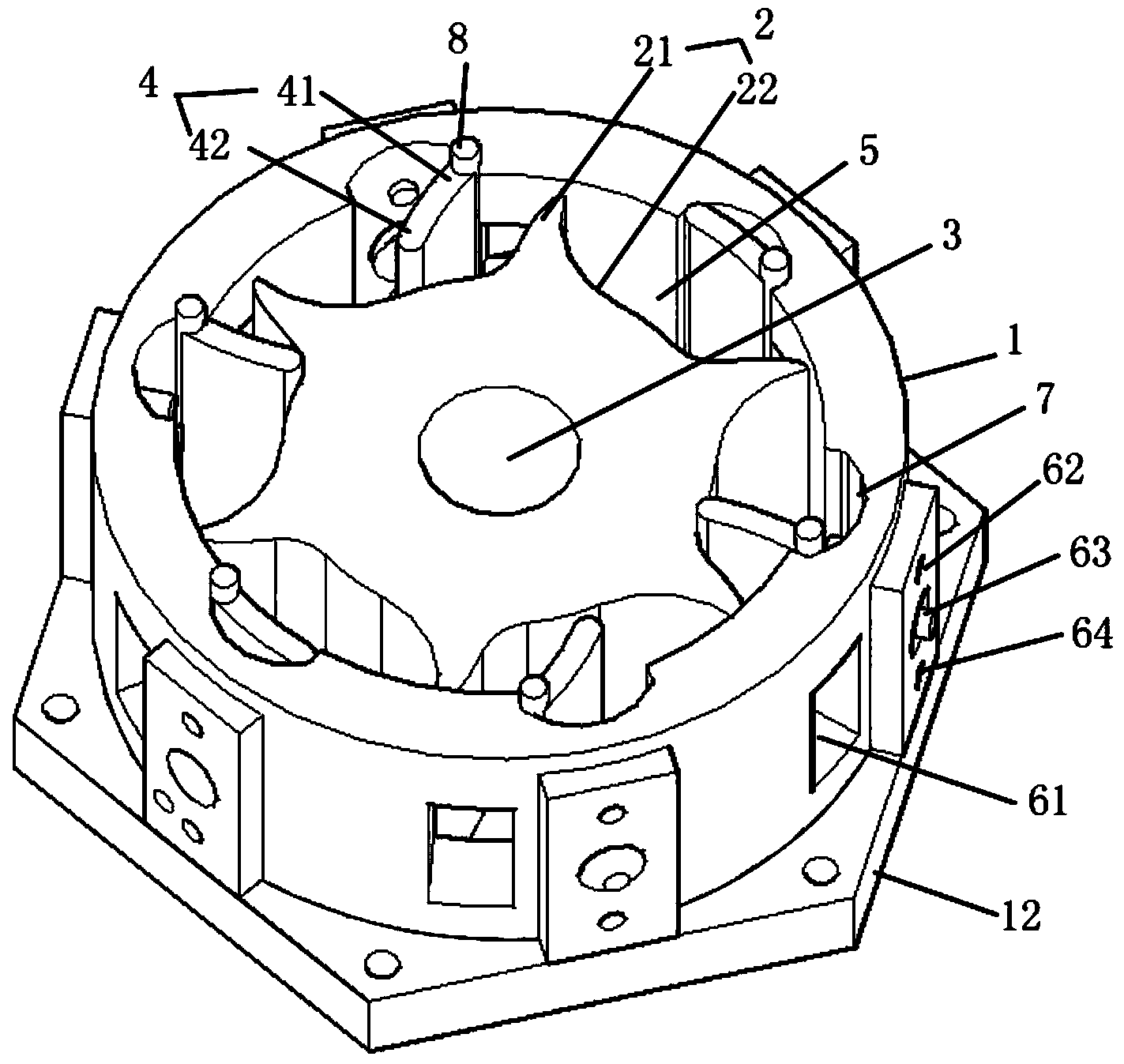

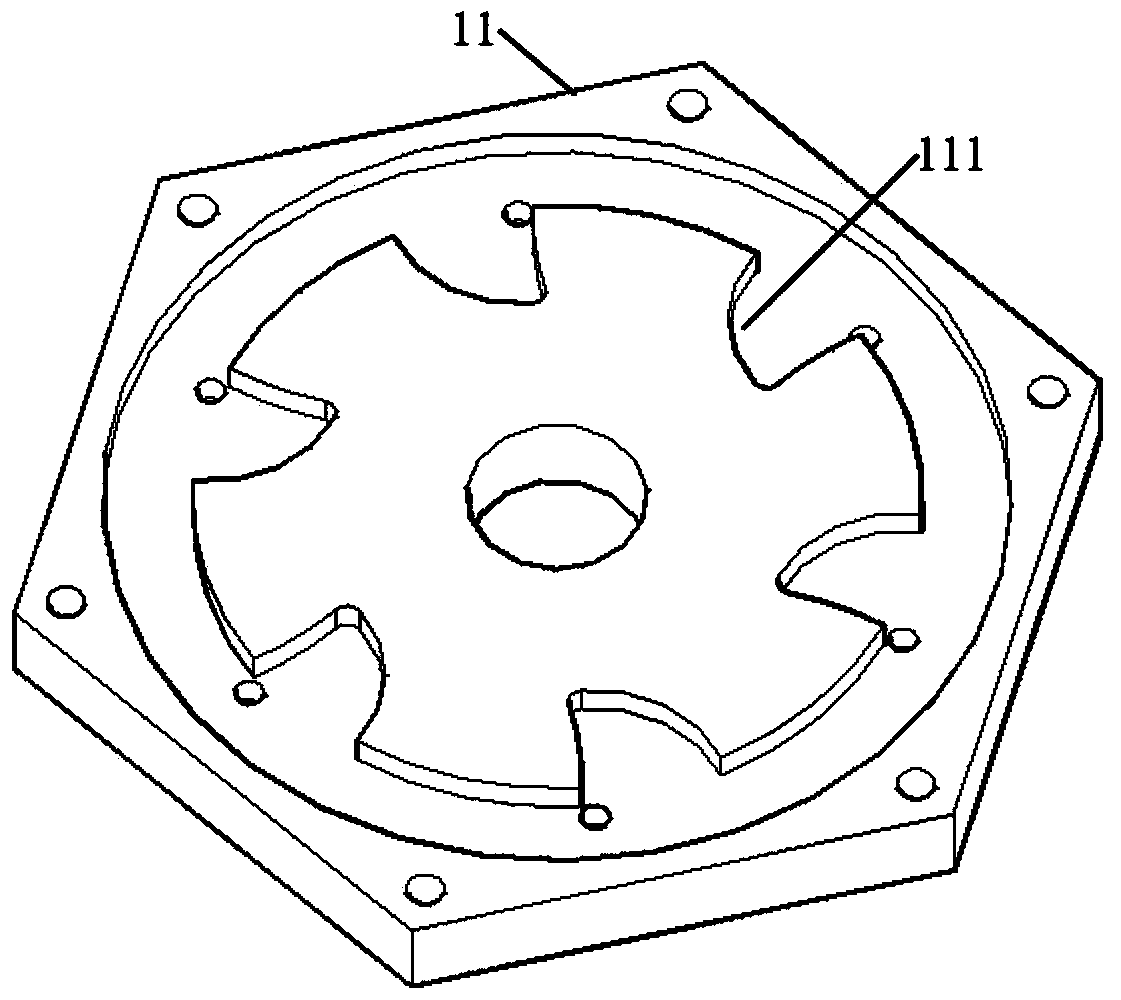

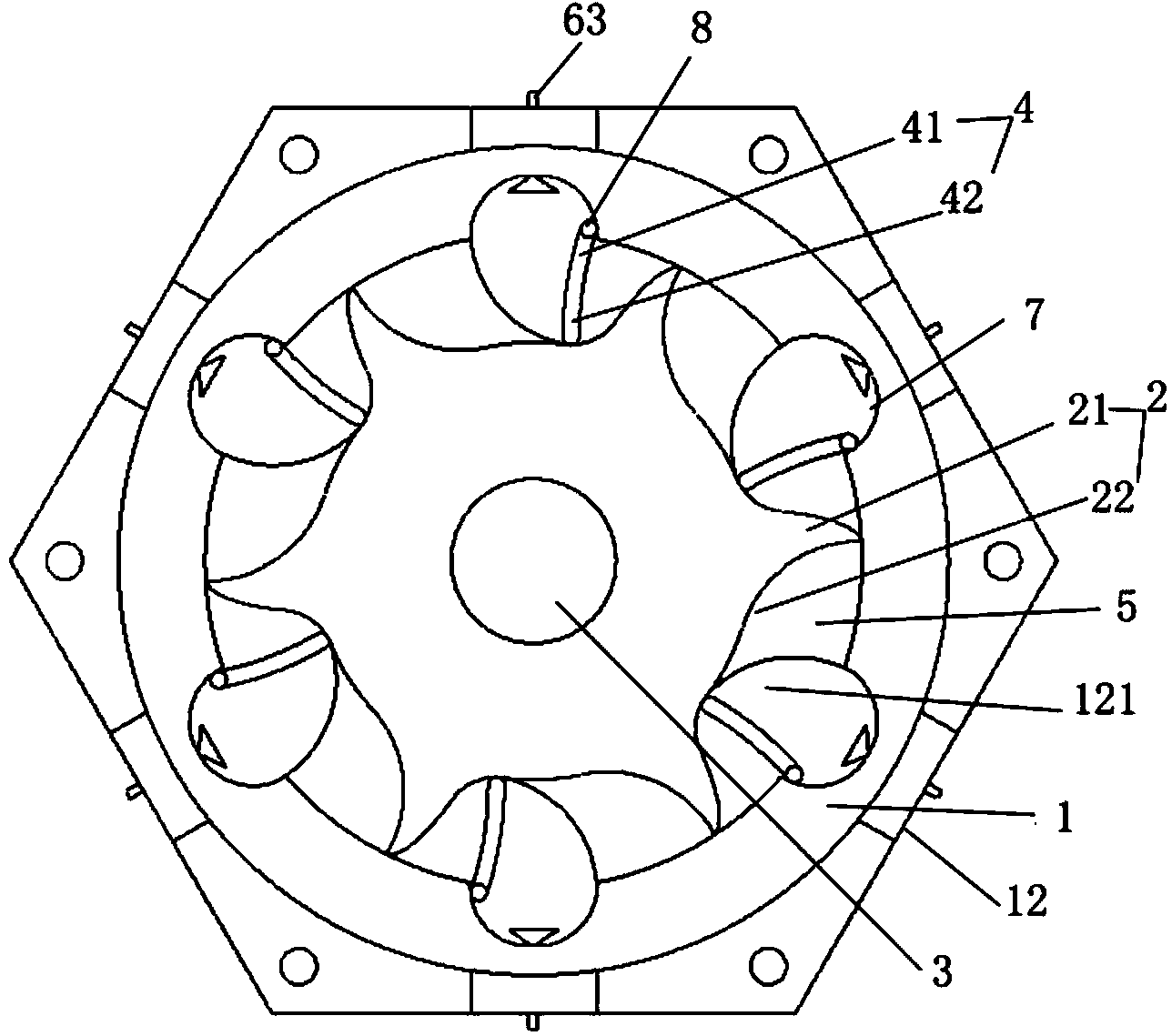

[0039] The invention provides a geared rotor 2 engine, which belongs to the internal combustion engine, and its material is preferably cast iron or cast aluminum. Such as Figure 1-2 As shown, in terms of structure, the engine mainly includes a stator 1, a rotor 2, an output shaft 3 and a dial 4; wherein, the external shape of the above-mentioned stator 1 is, for example but not limited to, a regular hexagonal column or a cylinder, etc., in the stator 1 There is a cylindrical cavity inside for accommodating the rotor 2 and the output shaft 3. The upper and lower ends of the stator 1 are also provided with an upper end cover 11 and a lower end cover 12 respectively. The screw is tightened so that the cavity inside the stator 1 forms a closed cavity.

[0040] The above-mentioned rotor 2 is a geared rotor, and the rotor 2 includes gear teeth 21 and tooth slots 22 formed between two adjacent gear teeth, wherein there are at least two gear teeth 21, as a rotary piston, preferably,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com