Clay tile blank supporting and drying device

A drying device and a technology for tile blanks, which are applied in the directions of drying gas arrangement, progressive dryer, drying of solid materials, etc., can solve the problems of low production efficiency, unsuitable ceramic tile blanks, long drying time, etc., to improve product quality and Production efficiency, the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

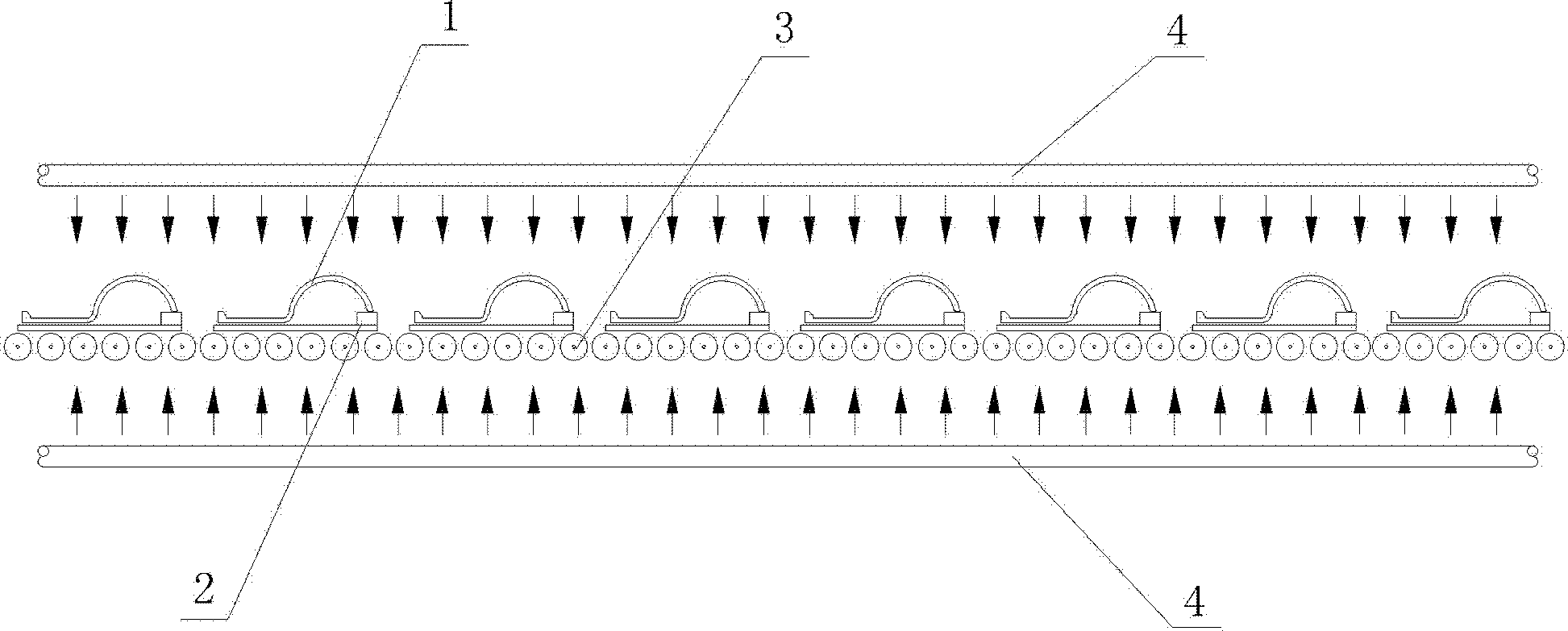

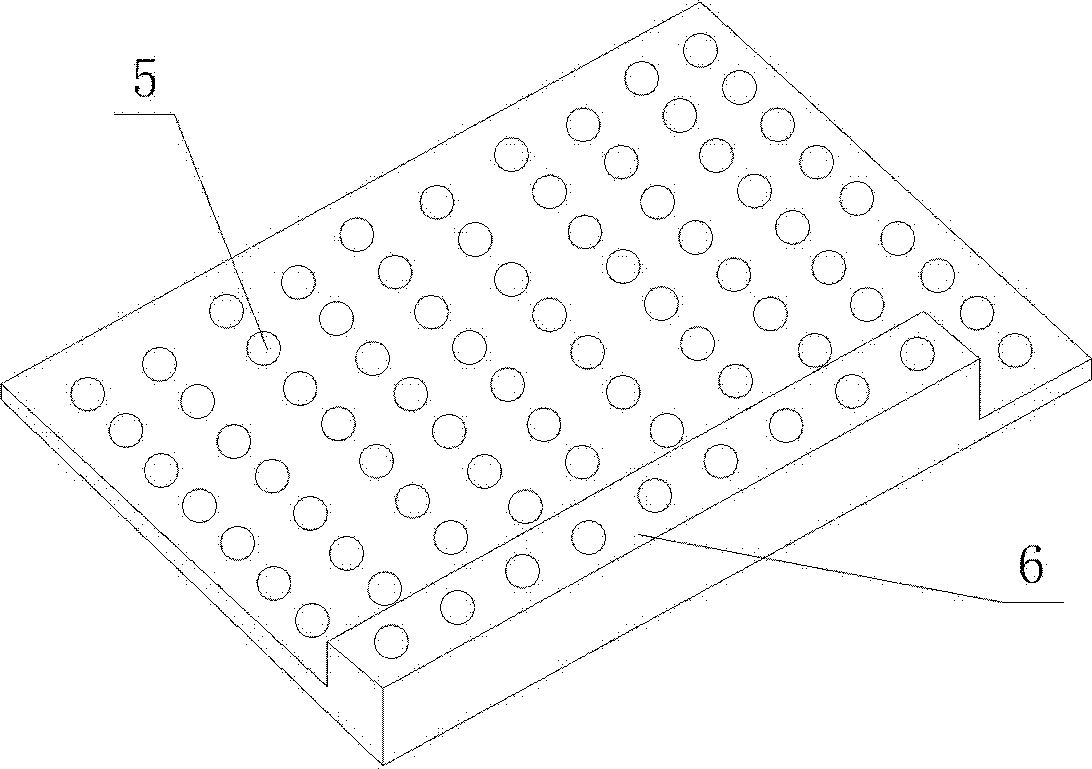

[0016] A clay tile supporting drying device comprises a roller table drying kiln and a tile supporting frame 2 . The roller-type drying kiln is divided into two types: single-layer and multi-layer, and each layer of the multi-layer roller-type drying kiln is controlled independently. Roller drying kilns are superimposed into multiple layers. The roller table drying kiln includes a roller table 3 and an air supply pipe 4. The roller table 3 is formed by arranging a plurality of roller bars, and each roller bar rotates in the same direction driven by a motor. After the tile blank 1 is formed by extrusion and pressing, the tile blank 1 is supported by the tile blank support frame 2 and transported to the roller type drying kiln for drying. The tile support frame 2 is designed according to different tile types, mainly to solve the problem that the bottom surfaces and support points of tile blanks 1 of different tile shapes are not on the same plane, and cannot walk smoothly on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com