Wet etching process and equipment, and solar cell and manufacturing method thereof

A technology for solar cells and solar cells, applied in the field of solar energy, can solve the problems of etching black lines and rising square resistance, and achieve the effects of improving electrical performance parameters, reducing use costs, and achieving good polishing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

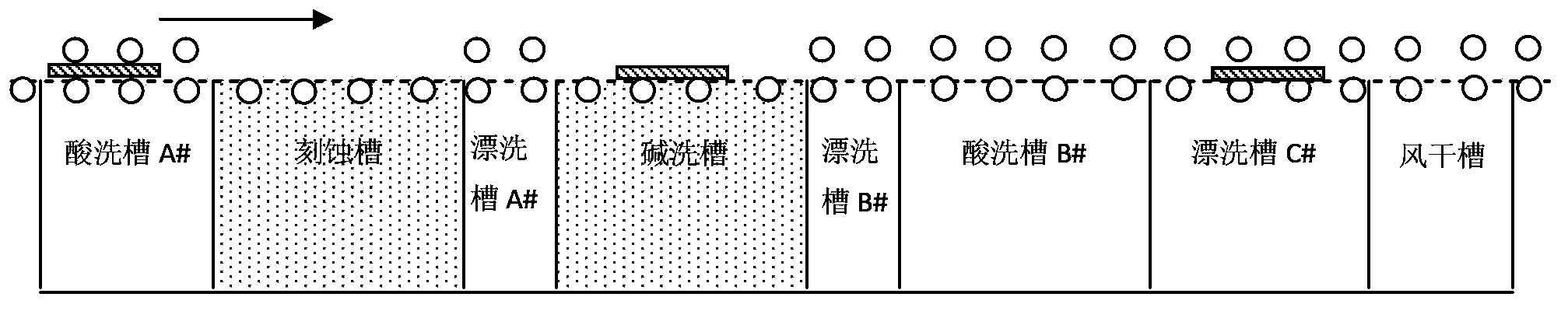

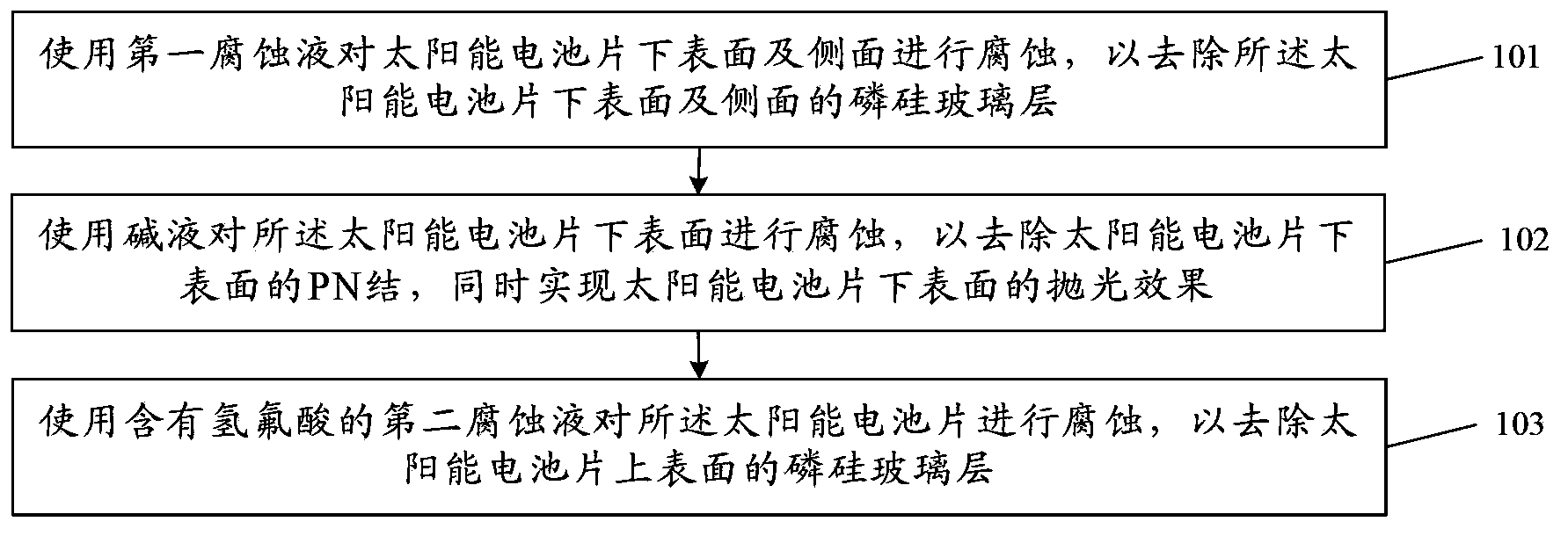

[0055] Embodiments of the present invention provide a wet etching process, such as figure 2 shown, including:

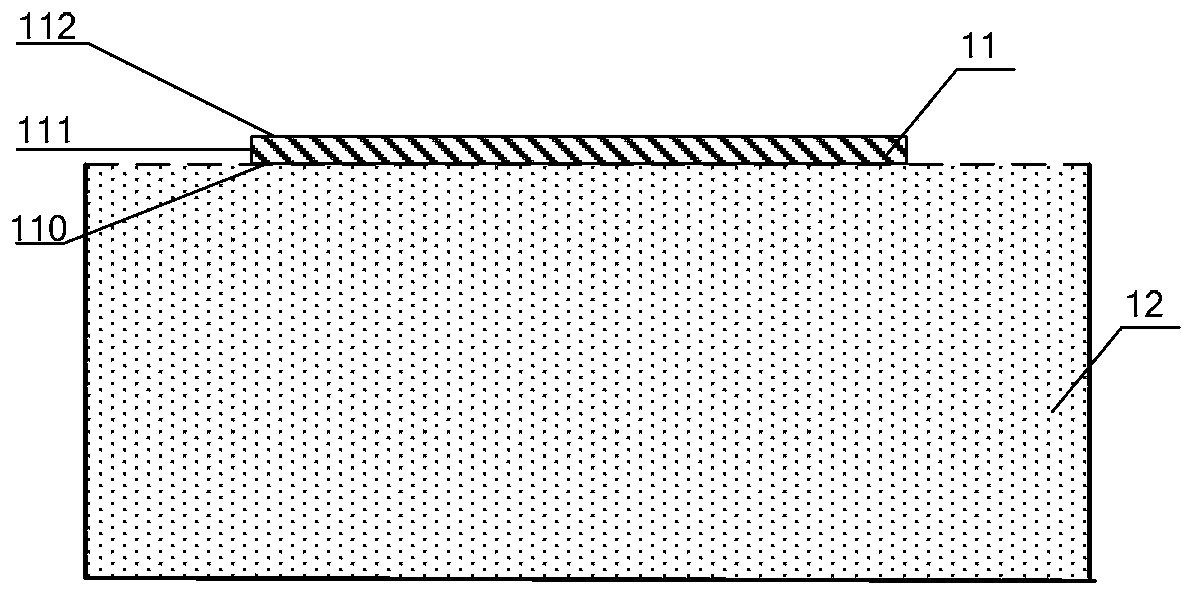

[0056] 101. If image 3 As shown, the lower surface 110 and the side surface 111 of the solar battery sheet 11 are etched and etched using the first etching solution 12 to remove the phosphosilicate glass layer on the lower surface 110 and the side surface 111 of the solar battery sheet 11. The first etching solution 12 is hydrofluoric acid solution;

[0057] In this embodiment, the upper surface (front side) 112 of the solar battery sheet 11 refers to the side of the solar battery sheet 11 that is finally formed with a PN junction, and the lower surface (back or backlight surface) 110 of the solar battery sheet 11 refers to the uppermost surface of the solar battery sheet 11. The other surface opposite to the upper surface 112 , the side surface 111 refers to the connection surface between the upper surface 112 and the lower surface 111 .

[0058] In this step, ...

Embodiment 2

[0089] For crystalline silicon solar cells, the phosphosilicate glass layer formed after diffusion is a recombination region for carriers and must be removed. In the existing etching process, the removal of the back junction is carried out in the etching tank, and hydrofluoric acid and nitric acid are used for reaction etching. However, the reaction between silicon and acid is an isotropic reaction, and the reaction rate is very fast. Therefore, in order to ease the reaction rate and prevent the backside corrosion from being too strong, the proportion concentration of the acid in the etching tank should not be too high, and it is required to be carried out at a low temperature, in order to achieve the back junction can be completely corroded, and at the same time, it will not affect the front PN. The effect of causing adverse effects. Since the depth of the PN junction on the back is very shallow (generally within 0.3um), after wet etching, the corrosion degree on the back of ...

Embodiment 3

[0112] In addition, the present invention also provides a solar cell, comprising a substrate having a P-type layer and an N-type layer, one side of the substrate has a back electrode, and the other side of the substrate has an anti-reflection film, and the anti-reflection film There is a front electrode passing through the anti-reflection film and in contact with the substrate, and the solar cell undergoes any wet etching process described in Embodiment 1 during the manufacturing process.

[0113] Compared with the prior art, the solar cell mentioned in the present invention removes the phosphosilicate glass layer and completes the back junction and back polishing at the same time during the manufacturing process. The electrical performance parameters have been improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com