Astragalus wall-broken preparation

A technology of Astragalus membranaceus preparations, which is applied in the field of astragalus membranaceus wall-breaking preparations, can solve the problems of loss of active ingredients, increase of powder specific surface area, easy moisture absorption, etc., and achieves the advantages of being easy to drink with warm water, strong stability of the finished product, and easy disintegration and dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

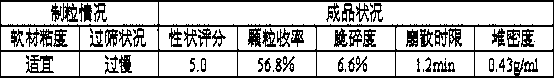

[0023] Take the medicinal material of Astragalus membranaceus, coarsely pulverize it into a coarse powder of about 100 meshes, and then ultrafinely pulverize it into a powder in which 90% of the particle size of the ultrafine powder is less than or equal to 45 μm, and add ethanol-water solution (the mass fraction of ethanol is 20% ) soft material by wet method, the ratio of solution to superfine powder is 0.6︰1 (by weight), after mixing, pre-installed 10-mesh sieve, the extrusion speed is 50r / min, and the extrusion force is 1MPa to make wet granules , the wet granules were placed in a hot air circulation oven, the drying temperature was set at 85°C, and dried for 2.5 hours until dry, and the astragalus wall-broken preparation was obtained after sieving the whole granules.

[0024]

[0025] Note: The full score is 10.

Embodiment 2

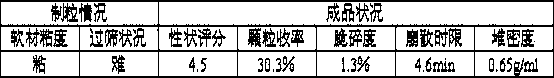

[0027] Take the medicinal material of Astragalus membranaceus, coarsely pulverize it into a coarse powder of about 100 meshes, and then superfinely pulverize it into a powder in which 90% of the particles in the ultrafine powder have a particle size less than or equal to 45 μm, and add ethanol-water solution (the mass fraction of ethanol is 40% ) soft material by wet method, the ratio of solution to superfine powder is 0.9︰1 (by weight), after mixing, pre-installed 10-mesh sieve, the extrusion speed is 70r / min, and the extrusion force is 0.9MPa to make wet Granules, wet granules are transferred to a vacuum microwave drying oven, set the drying temperature to 45°C, and dried for 0.75h until dry.

[0028]

[0029] Note: The full score is 10.

Embodiment 3

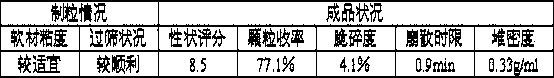

[0031] Take the medicinal material of Astragalus membranaceus, coarsely pulverize it into a coarse powder of about 100 meshes, and then superfinely pulverize it into a powder in which 90% of the particles in the ultrafine powder have a particle size less than or equal to 45 μm, and add ethanol-water solution (the mass fraction of ethanol is 60% ) soft material by wet method, the ratio of solution to superfine powder is 1.0︰1 (by weight), after mixing, pre-installed 30-mesh sieve, the extrusion speed is 80r / min, and the extrusion force is 0.3MPa to make wet Granules, wet granules are transferred to a hot air circulation oven, set the drying temperature to 85°C, and dried for 2.5 hours until dry.

[0032]

[0033] Note: The full score is 10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com