Hot forming trimming process production line

A thermoforming, production line technology, applied in transportation and packaging, vehicle parts, etc., can solve the problems of short service life of impact trimming blade, reduce investment costs, reduce table size, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings.

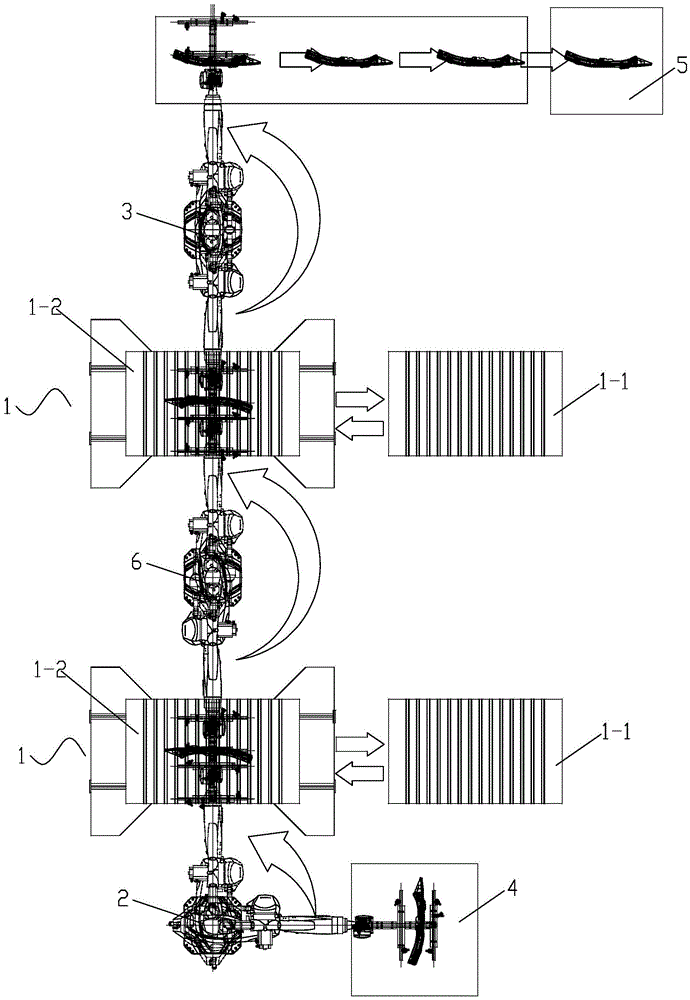

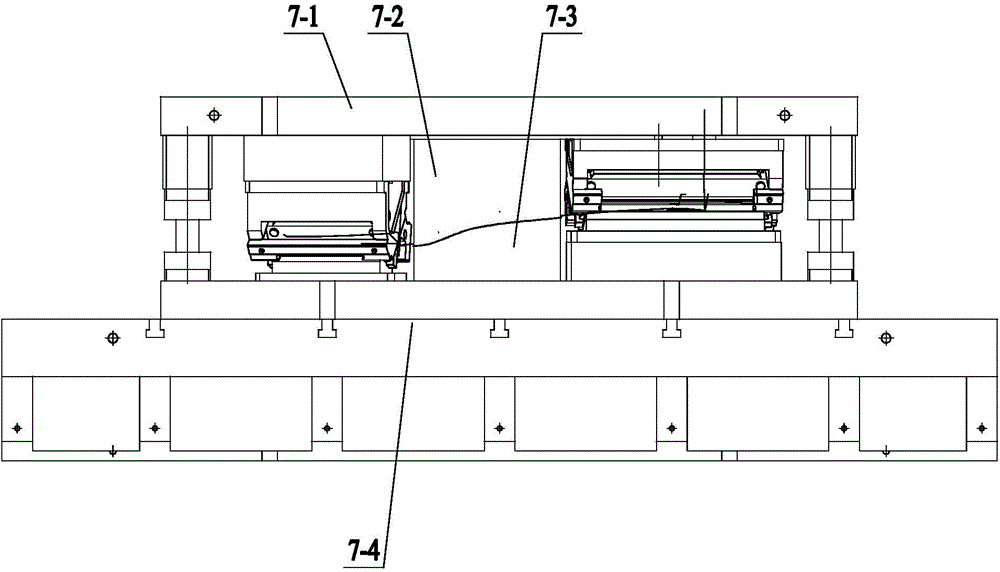

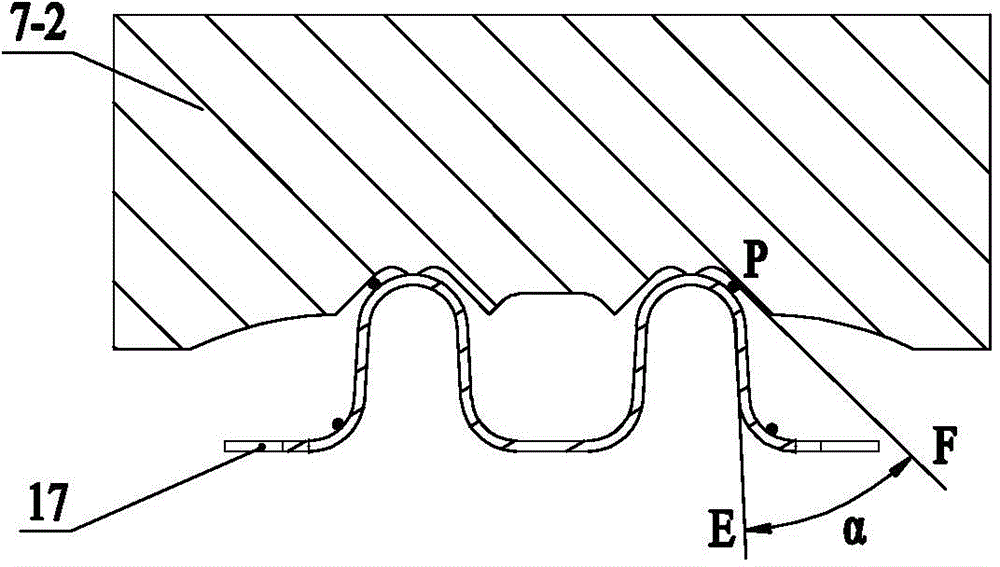

[0019] Such as figure 1 As shown: the thermoforming trimming process production line includes a press 1, an upper working table 1-1, a lower working table 1-2, a feeding device 2, a feeding device 3, a feeding frame 4, a receiving frame 5, Conveying device 6, upper mold base 7-1, upper mold insert 7-2, lower mold insert 7-3, lower mold base 7-4, workpiece 17, etc.

[0020] Such as figure 1 As shown, the present invention includes a feeding frame 4 and a receiving frame 5, 2 to 4 presses 1 are sequentially arranged between the feeding frame 4 and the receiving frame 5, and a feeding device 2 is arranged on one side of the feeding frame 4 , a blanking device 3 is set on one side of the receiving frame 5, and a conveying device 6 is set between the two presses 1;

[0021] The press 1 is a hydraulic press or a servo press, which can press the workpiece with a set working pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com