Recycling processing system of cold-state carbon steel oxide scale powder suspension

A treatment system and suspension technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of no new type of cold-rolled carbon steel scale powder suspension Deal with reports and other issues to achieve good social and environmental benefits, reduce consumption, and operate easily.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

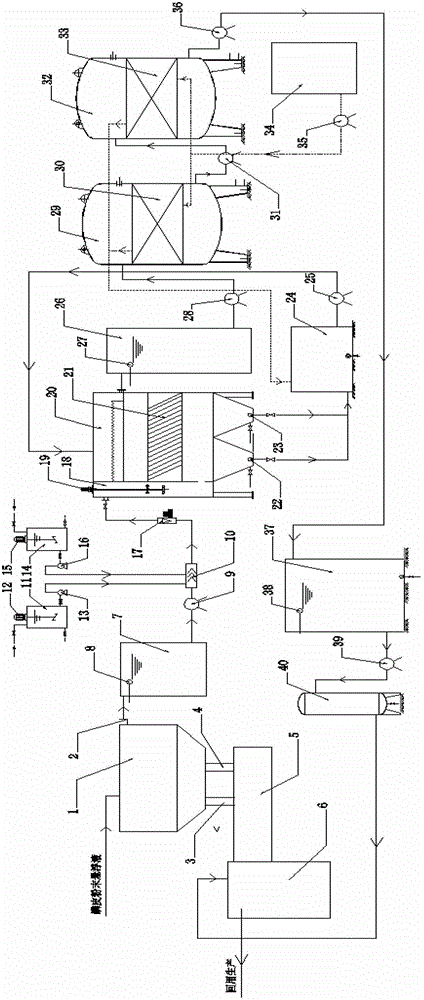

[0043] Please see attached figure 1 , the present invention is a cold carbon steel scale powder suspension recycling treatment system, which includes a sand liquid separation tank 1, a water outlet weir 2, a sand discharge pipe 3, a sand discharge pipe 4, a steel sand conveyor belt 5, a sand liquid Mixing device 6, scale powder suspension water tank 7, float level gauge 8, raw water lift pump 9, suspension pipeline mixer 10, coagulant dosing box 11, coagulation mechanical dosing agitator 12, coagulation Agent dosing metering pump 13, flocculant dosing box 14, flocculation dosing agitator 15, flocculant dosing pump 16, flow meter 17, coagulation and flocculation reaction tank 18, double blade electric agitator 19, swash plate Sedimentation tank 20, inclined plate 21, mud discharge pipe 22, mud discharge pipe 23, mud discharge tank 24, lift pump 25, filter water tank 26, liquid level gauge 27, primary lift pump 28, multi-media filter 29, multi-media Filter material layer 30, se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com