A C-type hair-fin condenser

A technology of condensers and fins is applied in the field of refrigeration and heat dissipation equipment, which can solve the problems of difficult diffusion of hot air, lower heat exchange efficiency, cuts on the operator's hand, etc., so as to improve heat exchange efficiency and improve heat dissipation effect. , the effect of facilitating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

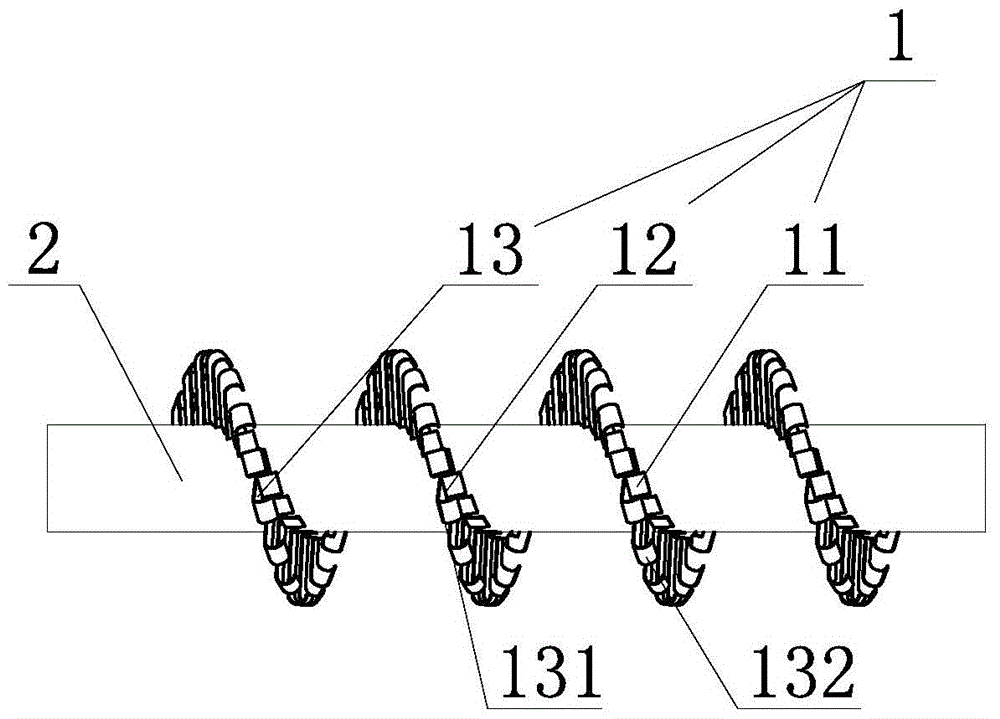

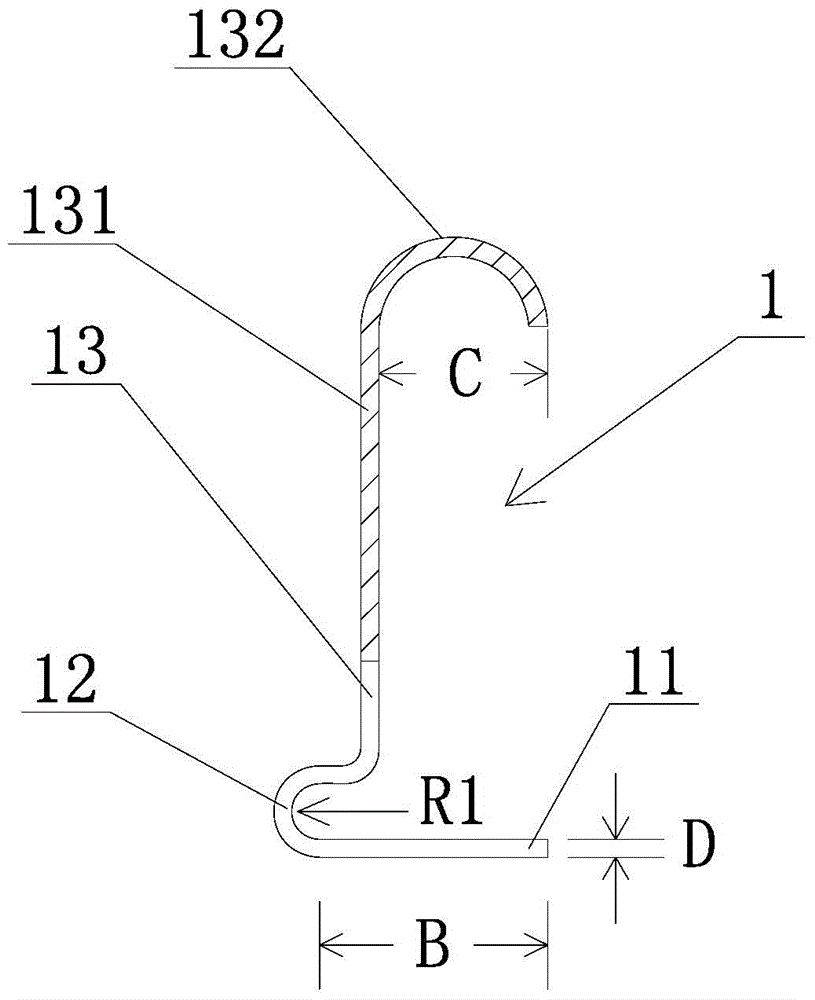

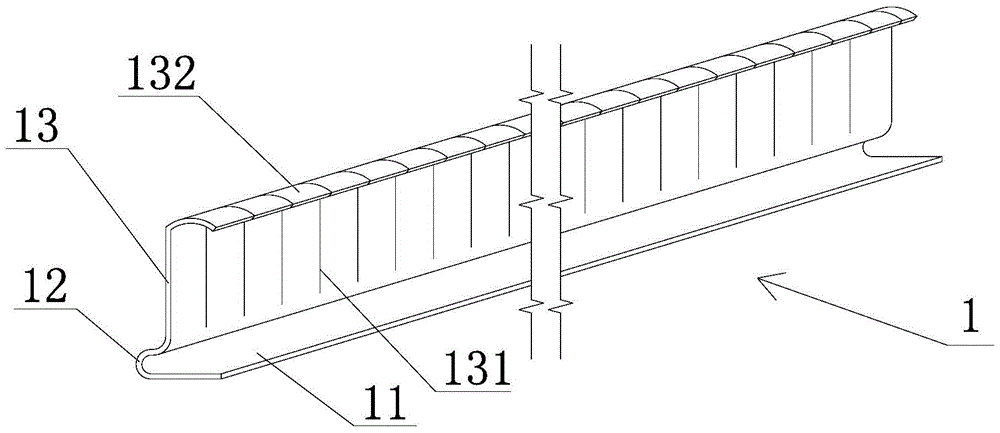

[0025] see Figure 1-Figure 3 As shown, a C-type hairy-fin condenser includes fins 1 and refrigeration tubes 2, and the outer wall of the refrigeration tube 2 is helically wound with fins; the fins 1 are integrally stamped from strip-shaped sheets , the fin 1 comprises a horizontal heat absorbing portion 11, a bent rib portion 12 and a vertical heat dissipation portion 13, the extension line of the lower end of the vertical heat dissipation portion 13 is perpendicular to the horizontal heat absorbing portion 11, and the vertical heat dissipation portion 13 is connected to the horizontal heat absorbing portion The parts 11 are integrally bent by bending the rib part 12, the bent rib part 12 is a circular arc surface structure, one end of the bent rib part 12 is horizontally connected with the horizontal heat-absorbing part 11, and the bent rib part The other end of the part 12 is vertically integrated with the vertical heat dissipation part 13, and the connection between the be...

Embodiment 2

[0035] A C-type hair-fin condenser, which is different from Embodiment 1 in that the thickness D of the fin 1 is 0.8mm; the width of the fin 1 is 17mm.

[0036] The width B of the horizontal heat absorbing portion 11 is 8mm; the vertical height A of the vertical heat dissipation portion 13 is 9mm; the arc width C of the arc surface 132 of the C-shaped structure at the upper end of the vertical heat dissipation portion 13 is equal to B; The fillet radius R1 of the arc surface structure of the bent rib portion 12 is 1.5mm.

[0037] The vertical height between the lower end of the slit 131 and the horizontal heat absorbing portion 11 is 4mm.

[0038] The strip width between two slits 131 is 4mm.

[0039] The pitch of the fins 1 on the refrigeration pipe 2 is 17mm.

[0040] The pipe diameter of the refrigeration pipe 2 is 8mm, and the pipe wall thickness of the refrigeration pipe 2 is 0.8mm.

[0041] The cooling tube 2 is a copper tube and the fin 1 is an aluminum sheet.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com