Belt drier

A technology for belt dryers and host machines, applied in progressive dryers, dryers, drying solid materials, etc., can solve problems such as no cleaning system, uneven cloth, cross-contamination, etc., to avoid cross-infection and improve drying Efficiency, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

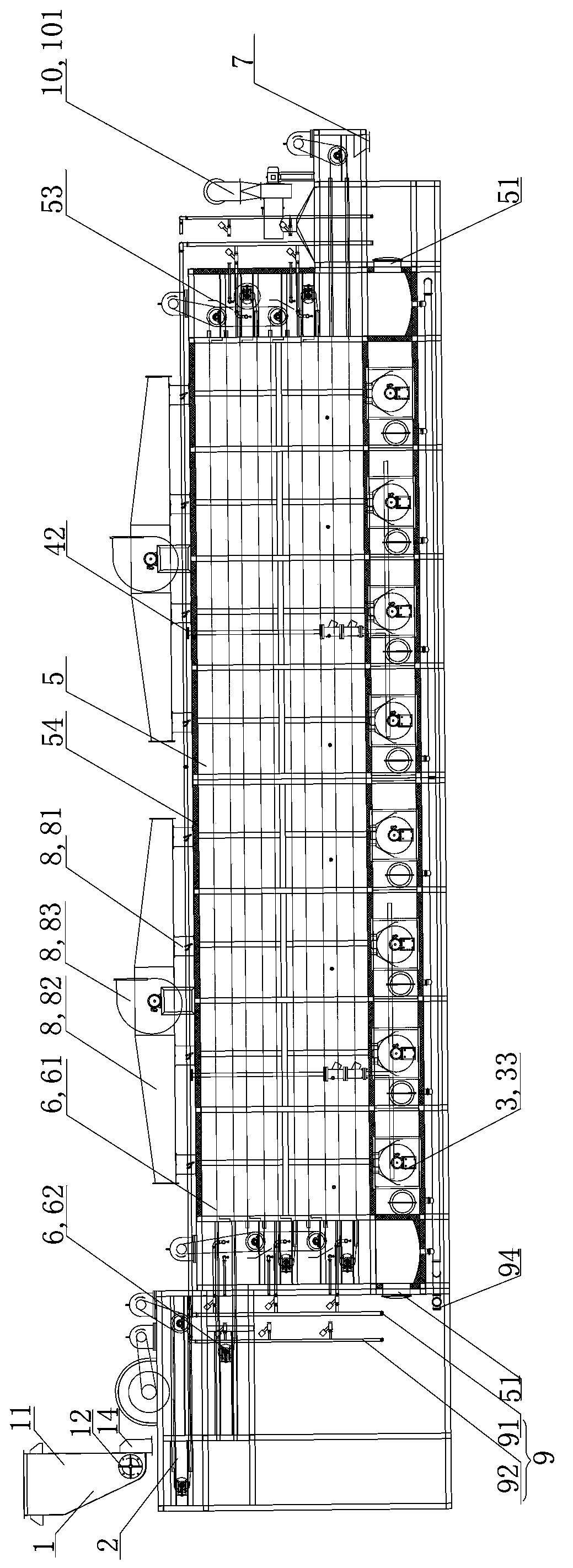

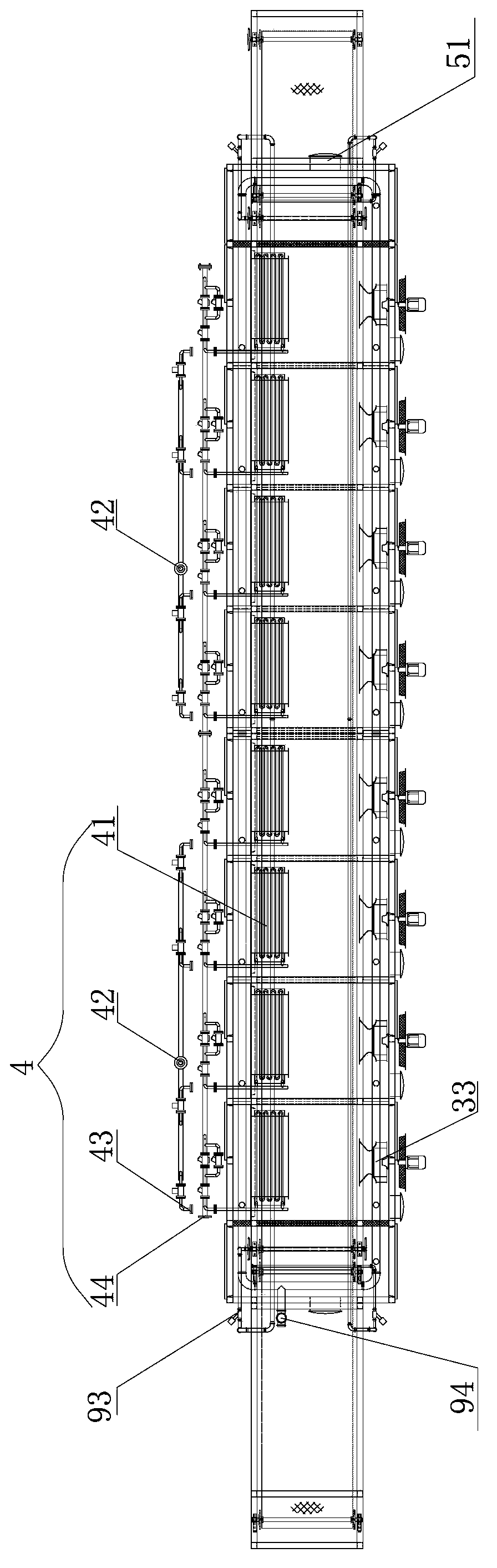

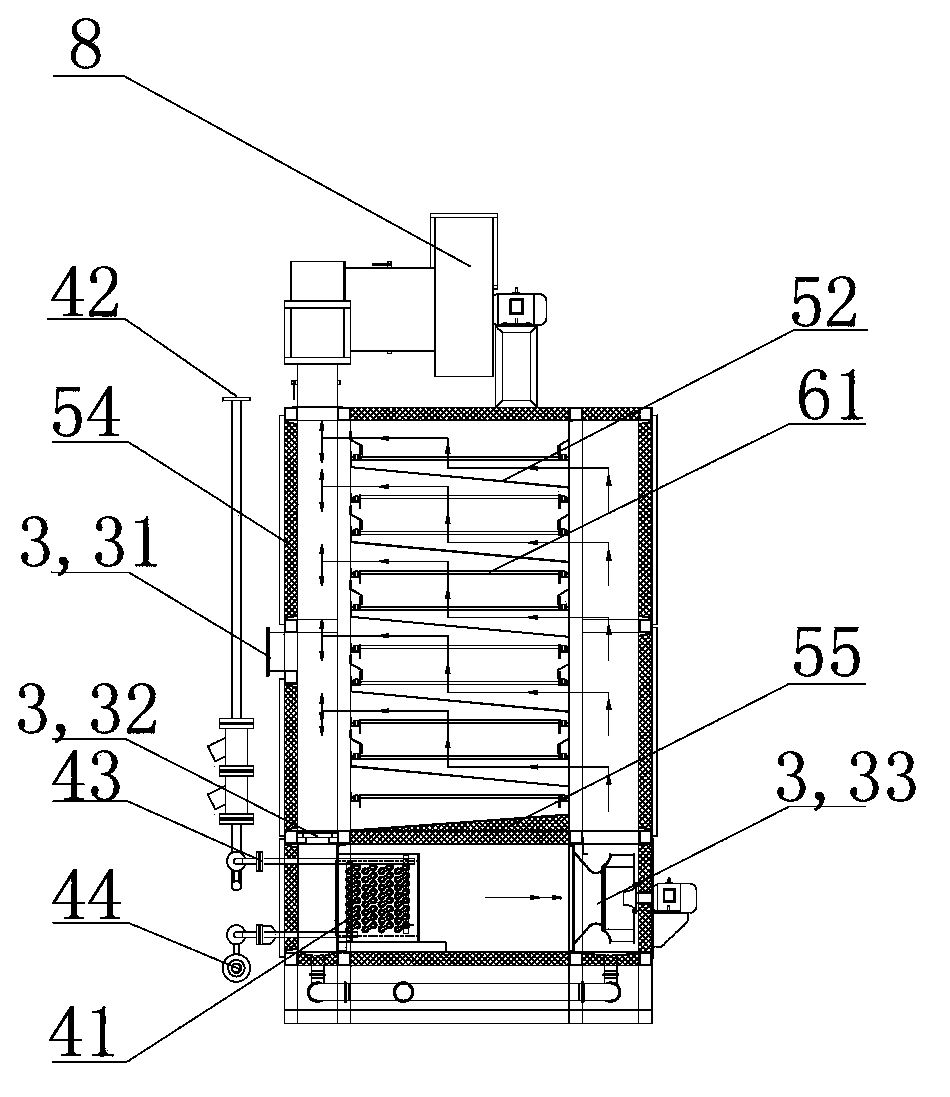

[0042] See Figure 1 to Figure 3 , the present invention has a feeding system 1, a material distribution system 2, an air inlet filter system 3, a heating system 4, a main frame 5 and a material transmission system 6 located in the main frame 5, a discharge system 7 at the lower part of one end of the primary frame 5, and an upper end of the primary frame 5. Exhaust / humidity system 8, cooling system 10 and control system; Material transmission system 6 comprises multi-layer mesh belt 61 and drive shaft 62 positioned at the two ends of mesh belt 61, and mesh belt 61 is driven by the chain at the two ends of drive shaft 62, this The invention can be designed into 2-8 layers of mesh belts 61 according to needs, and the present embodiment is 5 layers of mesh belts 61, which has met the needs in most cases; the cooling system 10 is a cooling fan 101 positioned at the end of the main frame 5; Cleaning system 9 is arranged, and cleaning system 9 comprises cleaning water pipeline 91 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com