Concrete carbonized protective layer bonding strength detector

A technology of bonding strength and protective layer, which is applied in the field of testing devices for the bonding strength of the protective layer, can solve the problems of large error in test results, complicated operation, and inability to apply on-site detection, etc., and achieves small error in test results, convenient operation, and excellent structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

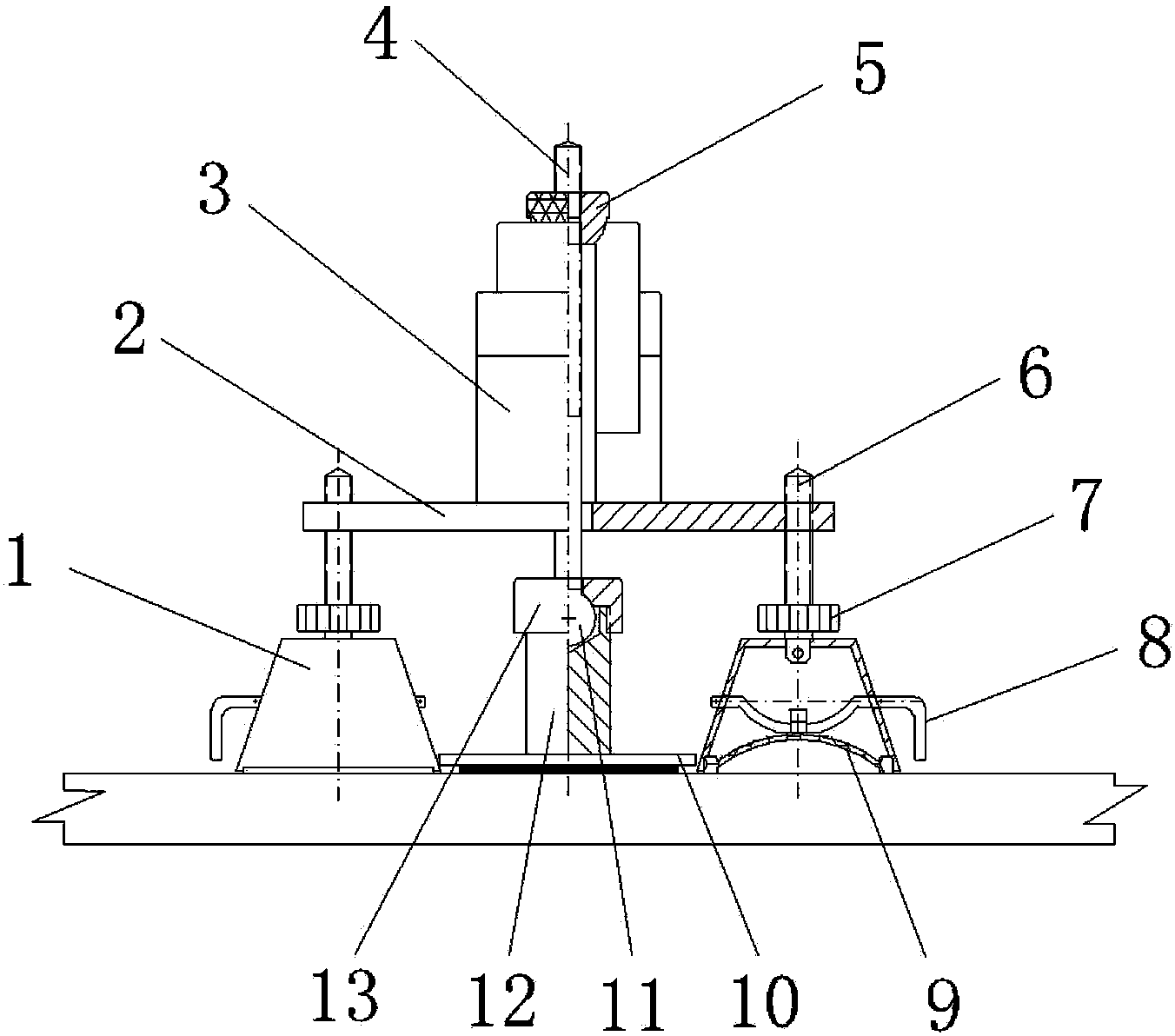

[0011] Such as figure 1 As shown, the concrete carbonization protective layer bond strength tester includes: a platen 2, a lifter 3 is provided in the middle of the plane on the platen, a matching lifting screw 4 is provided on the lifter, and an adjusting screw is provided on the upper side of the lifting screw. Nut 5, the adjusting nut cooperates with the upper end of the lifter, the lower end of the lifting screw 4 is provided with a ball head 11, the bottom of the platen is provided with an adhesion plate 10, and the adhesion plate 10 is provided with a matching ball head seat 12 and a gland nut 13 , the ball head 11 cooperates with the ball head seat and the gland nut respectively, a group of adjusting screw rods 6 are arranged on the periphery of the platen 2, an integral handwheel 7 is arranged on the lower side of the adjusting screw rod, and a supporting foot is arranged at the lower end of the adjusting screw rod 1. The shape of the supporting foot is a conical barre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com