Harmonic drive type high-accuracy position control system and method

A technology of harmonic drive and control system, applied in the direction of control using feedback, can solve problems such as increasing active damping, and achieve the effect of simple control method and convenient debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

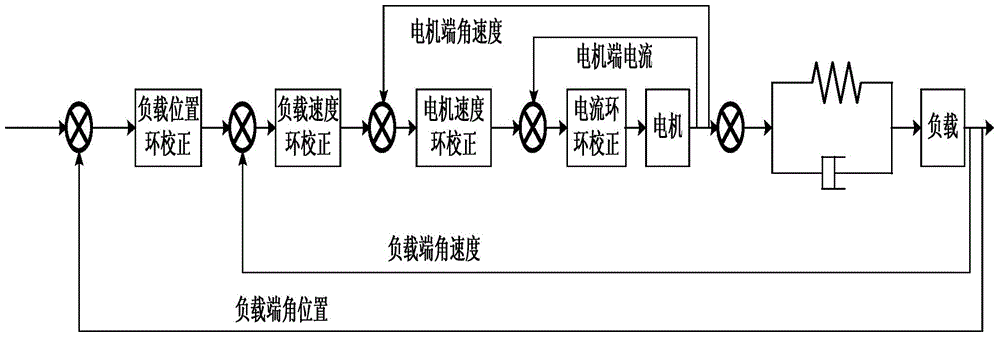

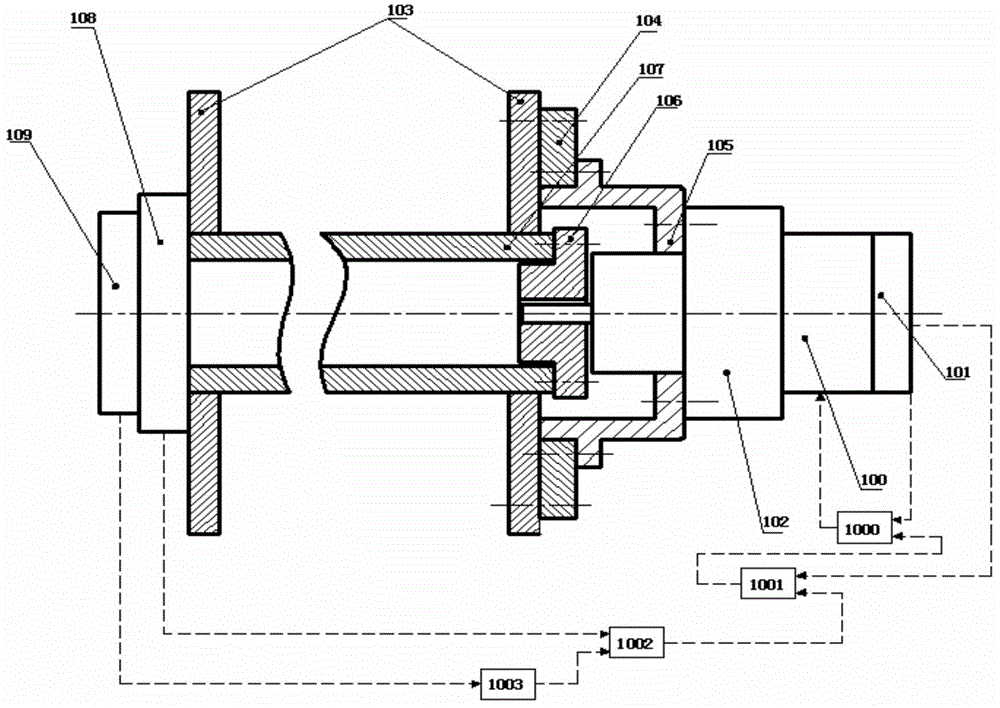

[0043] Such as figure 1 As shown, the control objects of the system include DC brushless motor 100, harmonic reducer 102 and load 107, and the harmonic reducer is simplified as a spring-damper system, so the control object can be regarded as two masses connected by spring damping system. The innermost loop to the outermost loop of the system are respectively the motor-side current loop, the motor-side speed loop, the load-side speed loop and the load-side position loop. The current of the motor is detected by the internal detection device of the motor driver 110 , and the speed of the motor is obtained by differentiating the position signal detected by the rotary encoder 101 at the motor end. The speed and position information of the load end can be obtained by the tachometer 108 and the photoelectric encoder 109 respectively.

[0044] The first step: system installation and connection. In order to avoid the loss of stiffness caused by the couplings as much as possible, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com