Control parameter setting method for steam turbine speed governing system

A technology of speed regulation system and control parameters, applied in the direction of control/regulation system, adaptive control, general control system, etc., can solve the problems of lack of research, low frequency oscillation of power grid, improper setting of proportional coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

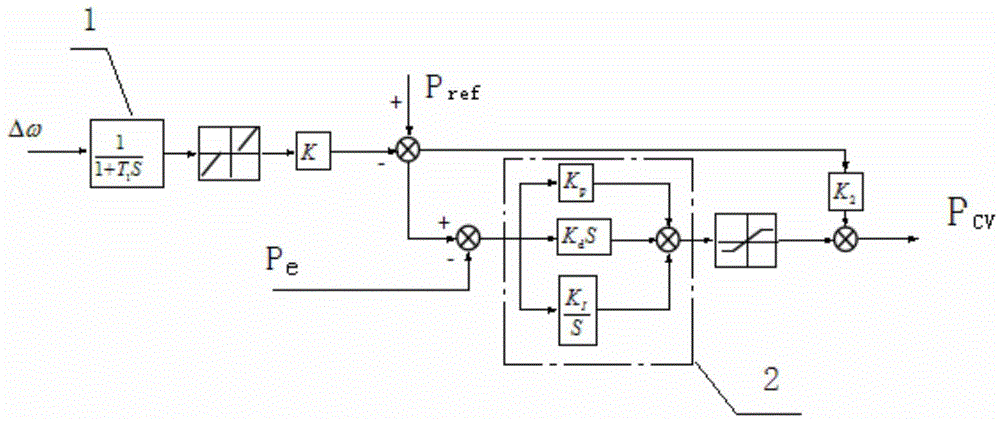

[0040] image 3 is the simulation model of the control system, and its transfer function after ignoring the nonlinear link is where T 1 Indicates the time constant of the speed transmitter, with a value of 0.02; the value of the slow rate of speed regulation is 0.025; the K behind the link of the slow rate of speed regulation represents the primary frequency modulation difference coefficient (that is, the speed unequal rate), and the value is 20; K p 、K i 、K d They are the proportional amplification factor, integral time constant, and differential time constant of the load controller PID, respectively, and the values are 1, 0.05, and 0; K 2 Indicates the speed feed-forward control amplification factor, the parameter is set to 1, image 3 Middle 1 is the speed transmitter. 2 is the PID load controller, P ref For a given activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com