Method for controlling content of N in bearing steel GCr15

A technology of bearing steel and N content, applied in the field of controlling N content in GCr15 bearing steel, can solve the problems of technological measures without N content, etc., and achieve the effects of improving cost performance and market competitiveness, reducing costs, saving energy and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

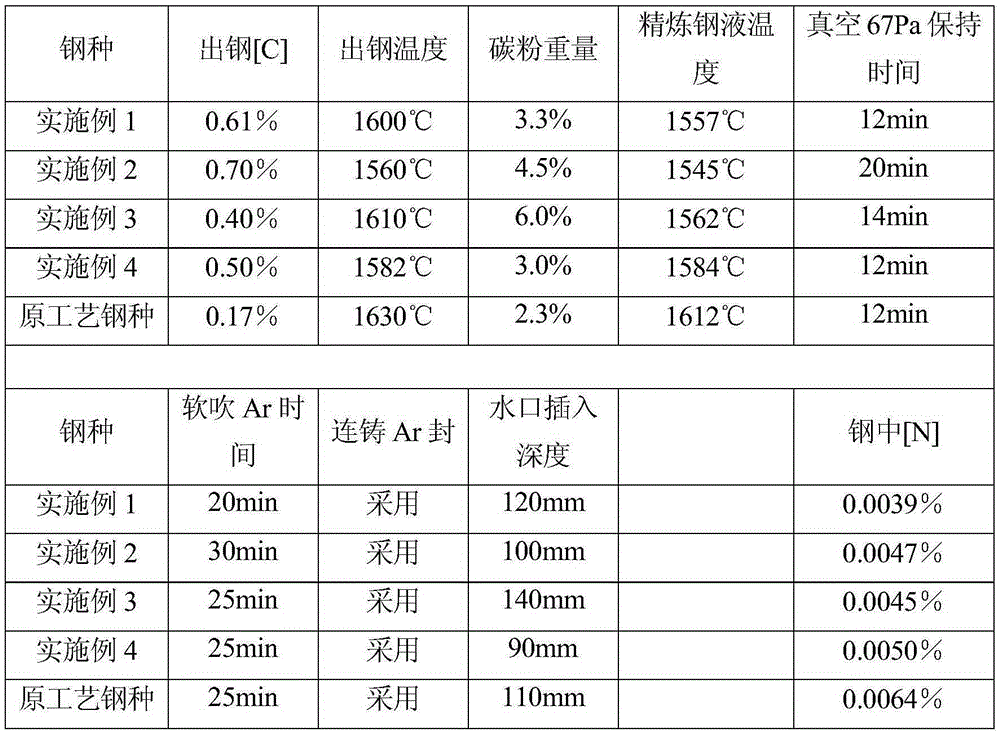

Embodiment 1

[0038] Converter smelting and tapping volume is about 150t, continuous casting slab section size: 200×200mm;

[0039] Sampling analysis composition before converter tapping: [C]: 0.61%, [P]: 0.013%, [S]: 0.029%, [N]: 0.0032%;

[0040] Temperature measurement before tapping: 1600°C;

[0041] The amount of LF slag in ladle refining is about 1.8t. After heating and arcing, 60Kg of carbon powder is spread on the refining slag with a spade (weight ratio: 3.3%) to form foam slag, and the thickness of the slag is about 450mm; : 1557°C; sampling analysis: [N]: 0.0052%;

[0042] The molten steel is vacuum treated in the RH furnace, the vacuum degree of the system is kept below 67Pa for 12 minutes, and the entire vacuum treatment time is 21 minutes; the soft Ar blowing time: 20 minutes, the Ar gas pressure: 0.26MPa, the flow rate: 125NL / min; sampling analysis: [N]: 0.0036%;

[0043] The long nozzle joint of the continuous casting ladle is sealed by spiral blowing Ar, and the Ar gas pre...

Embodiment 2

[0046] The electric furnace smelting and tapping volume are about 70t, and the cross-sectional size of the continuous casting slab is: 150×150mm;

[0047] Sampling analysis composition before electric furnace tapping: [C]: 0.70%, [P]: 0.007%, [S]: 0.021%, [N]: 0.0054%; temperature measurement before tapping: 1560℃;

[0048] The amount of LF slag in ladle refining is about 1.1t. After heating and arcing, 50Kg of carbon powder is spread on the refining slag with a spade (weight ratio: 4.5%) to form foam slag. The slag thickness is about 390mm; : 1545°C; sampling analysis: [N]: 0.0061%;

[0049] The molten steel is vacuum treated in the RH furnace, the vacuum degree of the system is kept below 67Pa for 20 minutes, and the entire vacuum treatment time is 25 minutes; the time of soft Ar blowing: 30 minutes, Ar gas pressure: 0.20MPa, flow rate: 100NL / min; sampling analysis: [N]: 0.0044%;

[0050] The long nozzle joint of the continuous casting ladle is sealed by spiral blowing Ar,...

Embodiment 3

[0053] Converter smelting and tapping volume is about 250t, continuous casting slab section size: 340×450mm;

[0054] Sampling analysis composition before tapping of converter: [C]: 0.40%, [P]: 0.016%, [S]: 0.024%, [N]: 0.0030%; temperature measurement before tapping: 1610℃;

[0055] The amount of LF slag in ladle refining is about 3.6t. After heating and arcing, spread 216Kg of carbon powder on the refining slag with a spade (weight ratio: 6.0%) to create foam slag with a thickness of about 500mm. Heating molten steel for 15 minutes, the temperature of molten steel : 1562°C; sampling analysis: [N]: 0.0052%;

[0056] The molten steel is vacuum treated in the RH furnace, the vacuum degree of the system is kept below 67Pa for 14 minutes, and the entire vacuum treatment time is 25 minutes; the time of soft Ar blowing: 25 minutes, Ar gas pressure: 0.28MPa, flow rate: 200NL / min; sampling analysis: [N]: 0.0041%;

[0057] The long nozzle joint of the continuous casting ladle is sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com