Combined clamp assembly optimizing method based on assembly dimension path diagram

A technology of combined fixture and assembly size, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of difficult to clearly display the assembly of combined fixtures, and achieve the effect of good representation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

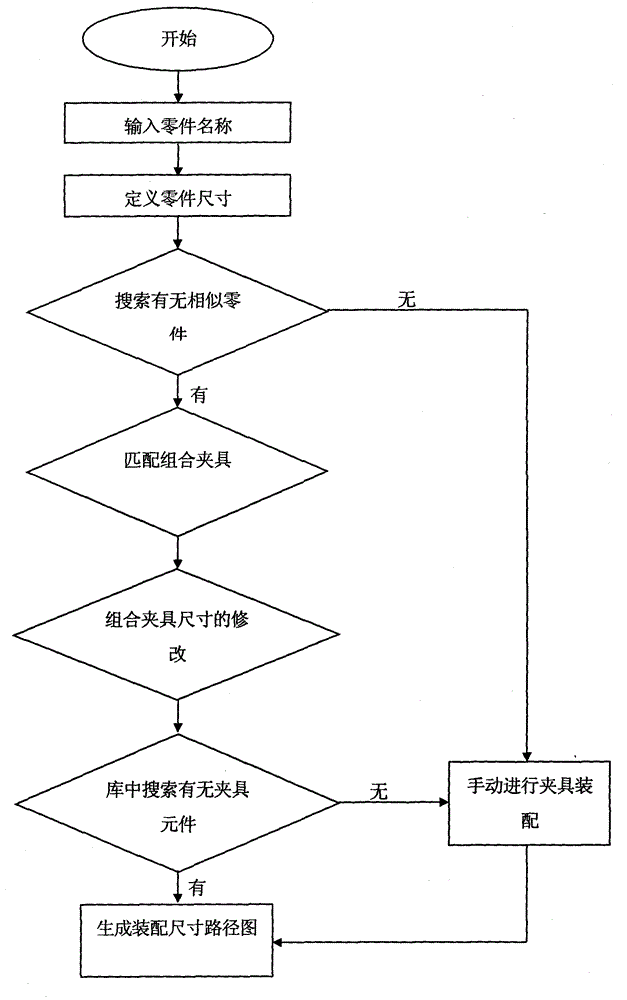

[0032] see figure 1 As shown, the specific process of the present invention's combined fixture assembly optimization method based on the assembly dimension path diagram is:

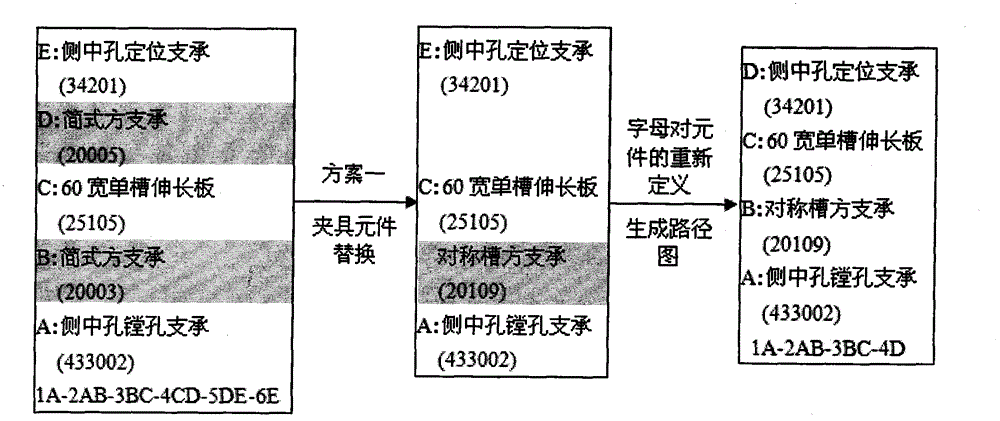

[0033] Step a, labeling of combined fixture components;

[0034] Use English letters in order from bottom to top, or from left to right to represent the fixture components in the combined fixture.

[0035] Each component in the component library is represented by an English letter, and the surface of the component is represented by a number plus a letter. The specific number and letter are determined according to the position of the component in the combined fixture. For example, the letter A is used to represent the combined fixture component, 1A and 2A represent the lower surface and the upper surface of the component respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com