PVC electronic connection line

A connecting wire and electronic technology, applied in the field of PVC electronic connecting wire, can solve the problems of prone to errors, affecting the use efficiency, low adhesion of electronic wires, etc., to achieve good high temperature resistance and combustion resistance, good flexibility, fire resistance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

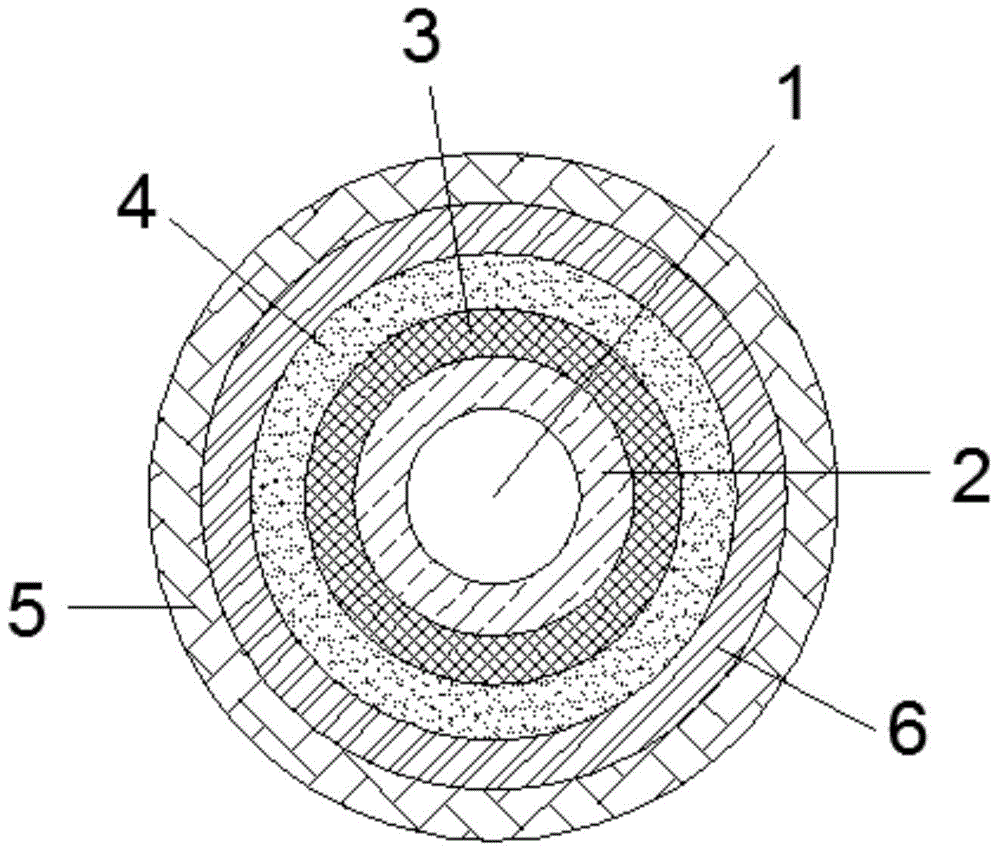

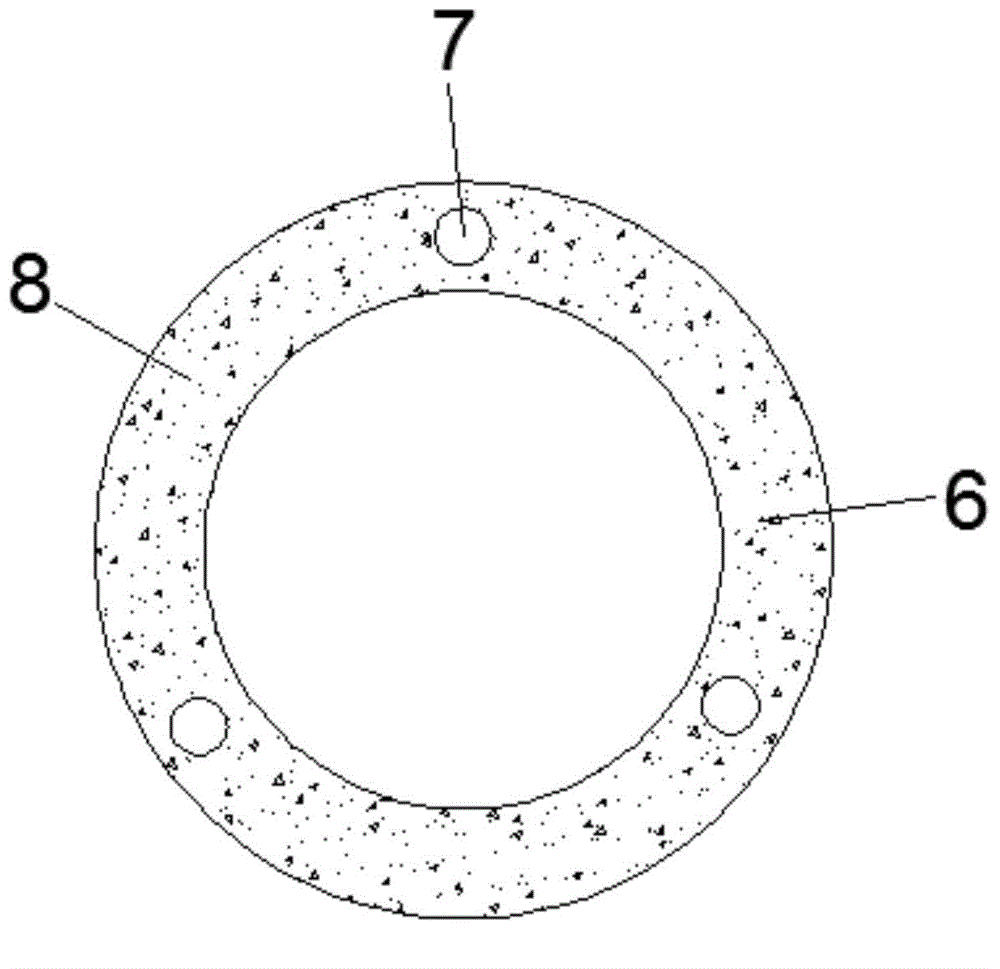

[0018] The PVC electronic connection wire of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, a PVC electronic connection wire includes a conductor 1 and an insulating layer 3 covering the conductor, a layer of fire-resistant mica tape 2 is arranged between the conductor 1 and the insulating layer 3, and a layer of outer layer is arranged outside the insulating layer 3 Insulation layer 5, the outer insulation layer 5 is a PVC layer, a fire-resistant oxygen barrier layer 4 is arranged between the insulation layer 3 and the outer insulation layer 5, and a fire-resistant mica layer 2 and a fire-resistant isolation layer are simultaneously set in the PVC electronic connection wire 4. Not only can it effectively play a role in fire prevention, but also can avoid the release of harmful acid gas from PVC burning when burning, so it is safe to use.

[0020] Further, the thickness of the fire-resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com