Formation method of semiconductor device

A semiconductor and device technology, applied in the field of semiconductor device formation, can solve problems such as poor performance of transistors, achieve the effects of enhancing reliability and stability, adjusting threshold voltage, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

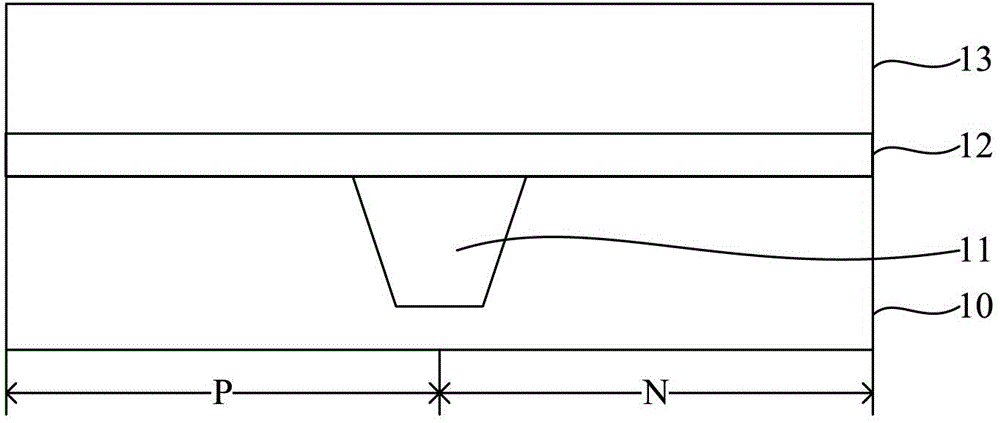

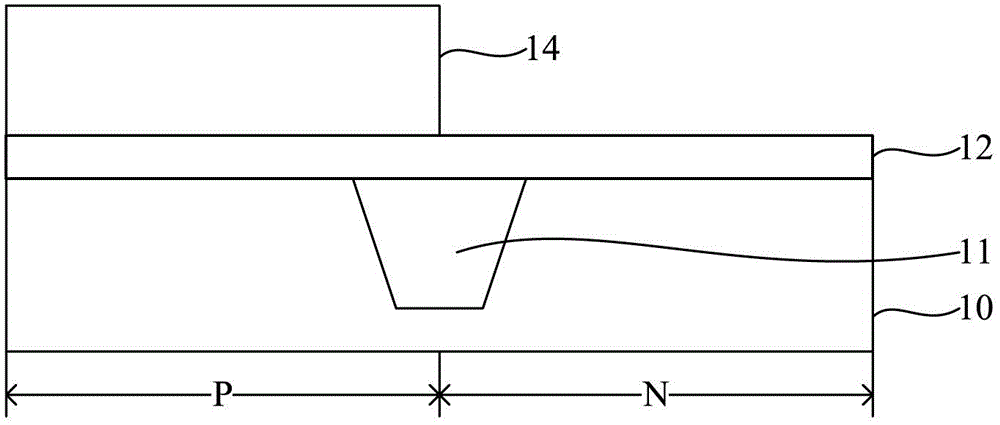

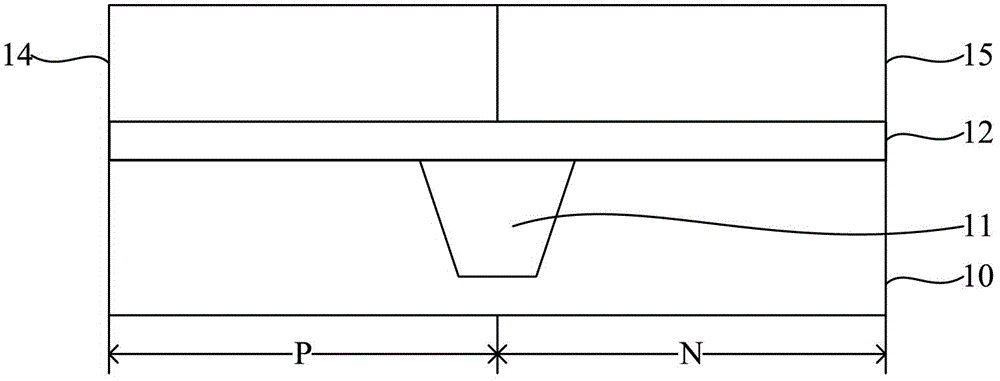

[0049] The inventor has conducted research on the problems existing in the prior art and found that: with reference to figure 2 and image 3 , when etching to remove the TiAlN layer in the N-type active region, it will damage the HfO by over-etching 2 Layer 12. Damaged HfO 2 As the layer becomes thinner, the TiN in the subsequent process of forming the TiN layer 15 of the N-type active region may diffuse into the substrate 10, which will affect the reliability and stability of the NMOS transistor. Moreover, HfO 2 As the thickness of the gate dielectric layer decreases, the gate leakage current will increase, resulting in poor performance of the transistor.

[0050]The inventor obtained a new method for forming a semiconductor device through creative research. In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com