Tobacco moisture content and temperature regulation control method

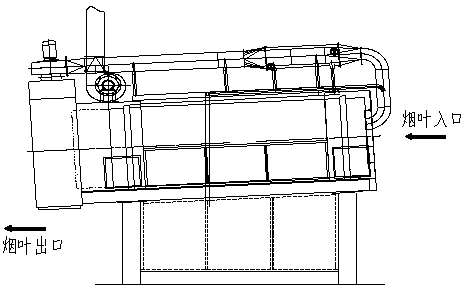

A control method and technology of moisture content, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of large investment, large space, inconvenient on-site logistics, etc., and achieve the effect of wide adjustable range, strong adaptability, and great promotion significance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

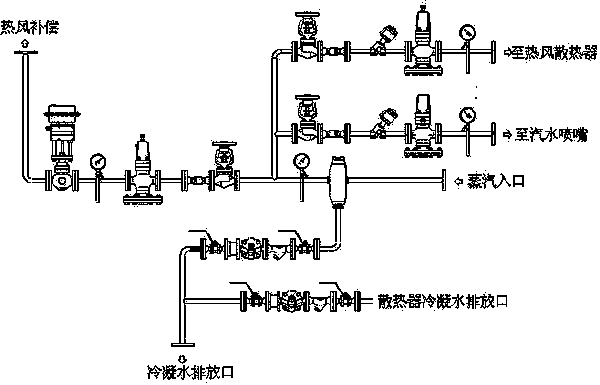

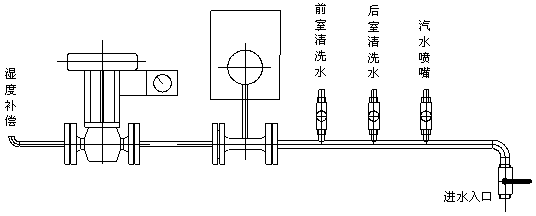

Method used

Image

Examples

Embodiment 1

[0061] A batch of online transit tobacco leaves have a moisture content of 22.8-23.4% and a temperature of 29-30°C (close to room temperature), which is compared with process requirements (water content 20.5±0.5%, temperature 45±5°C). , The moisture content of the tobacco leaves is significantly higher than the technological requirements, while the temperature of the tobacco leaves is not much different. The system adopts a combination of serial numbers 4 and 6, that is, adjust the tidal exhaust door, the frequency of the hot air fan or the air door, when the moisture content of the tobacco leaves meets the technological requirements , The temperature of the tobacco leaves is slightly higher (about 55℃), then adjust the steam valve position of the radiator appropriately. After about 12 minutes, the moisture content and temperature of the tobacco leaves reached the technological requirements.

Embodiment 2

[0063] A batch of online transit tobacco leaves have a moisture content of 18.4-18.8% and a temperature of 8-10°C (close to room temperature), which is higher than the process requirements (moisture content 20.5±0.5%, temperature 45±5°C). There is a big gap. The moisture content of the tobacco leaves is lower than the technological requirements, and the temperature of the tobacco leaves is much lower than the requirements. The system adopts a combination of serial numbers 1 and 2, that is, after preheating for about 20 minutes, the air duct steam compensation is turned on after feeding, and the system is measured The tobacco leaf temperature and the set value are controlled by PID closed loop until the temperature meets the process requirements; at the same time, the steam water injection is turned on, and the system will feed back the water added and the measured moisture content of the tobacco leaf for PID closed loop control until the moisture content of the tobacco leaf reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com