Cement concrete industry integrated product and realization method

A cement concrete and concrete technology, applied in the field of cement concrete, can solve the problems of insufficient utilization of mine resources, increase of concrete preparation costs, and decline in concrete performance, and achieve the effect of increasing price competitiveness, enhancing market competitiveness, and reducing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

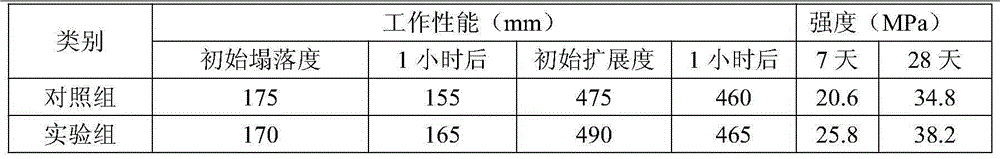

Embodiment 1

[0070] Realization method and product of cement concrete industry integration

[0071] Establish a cement factory near the mine, the cement factory is equipped with cement production equipment, aggregate production equipment, admixture production equipment, activator production equipment and admixture production equipment;

[0072] Set up concrete mixing stations in the adjacent project construction area;

[0073] Among them, the distance between the cement plant and the concrete mixing station is ≤150km; the distance between the concrete mixing station and the project construction area is ≤20km, and the number of concrete mixing stations is ≥1.

[0074] In the specific production, the stone in the mine is selected as the raw material of clinker, machine-made sand and aggregate, and the stone that does not meet the conditions of clinker, machine-made sand and aggregate is used as the raw material of the admixture;

[0075] The clinker, machine-made sand, large aggregate, smal...

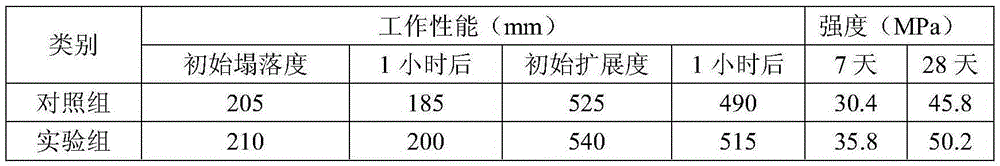

Embodiment 2

[0113] Cement concrete industry integration method and products,

[0114] Establish a cement factory near the mine, the cement factory is equipped with cement production equipment, aggregate production equipment, admixture production equipment, activator production equipment and admixture production equipment;

[0115] Set up concrete mixing stations in the adjacent project construction area;

[0116] Among them, the distance between the cement plant and the concrete mixing station is ≤150km; the distance between the concrete mixing station and the project construction area is ≤20km, and the number of concrete mixing stations is ≥1.

[0117] In the specific production, the stone in the mine is selected as the raw material of clinker, machine-made sand and aggregate, and the stone that does not meet the conditions of clinker, machine-made sand and aggregate is used as the raw material of the admixture;

[0118] The clinker, machine-made sand, large aggregate, small aggregate, ...

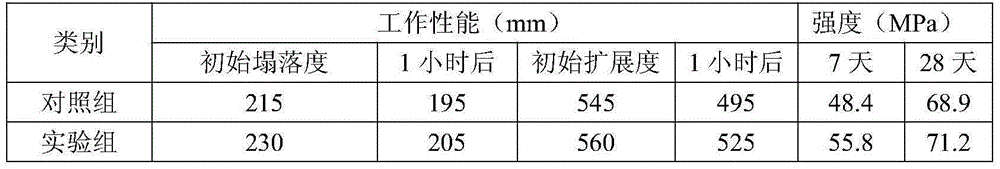

Embodiment 3

[0162] Realization method and product of cement concrete industry integration

[0163] Establish a cement factory near the mine, the cement factory is equipped with cement production equipment, aggregate production equipment, admixture production equipment, activator production equipment and admixture production equipment;

[0164] Set up concrete mixing stations in the adjacent project construction area;

[0165] Among them, the distance between the cement plant and the concrete mixing station is ≤150km; the distance between the concrete mixing station and the project construction area is ≤20km, and the number of concrete mixing stations is ≥1.

[0166] In the specific production, the stone in the mine is selected as the raw material of clinker, machine-made sand and aggregate, and the stone that does not meet the conditions of clinker, machine-made sand and aggregate is used as the raw material of the admixture;

[0167] The clinker, machine-made sand, large aggregate, smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com