Preparation method of high-purity salvianolic acid B

A technology of salvianolic acid and salvia miltiorrhiza, applied in the field of separation and purification of active components of traditional Chinese medicine, can solve problems such as difficulty, increase process steps, hinder the development of salvianolic acid B injection, and achieve low price, low cost, and environmental benefits the protective effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1. Add 100 g of Danshen medicinal material, add 1 L of water, stir and extract twice at 80° C. for 1 hour each time, filter, combine the two filtrates, and concentrate the filtrate to 200 mL.

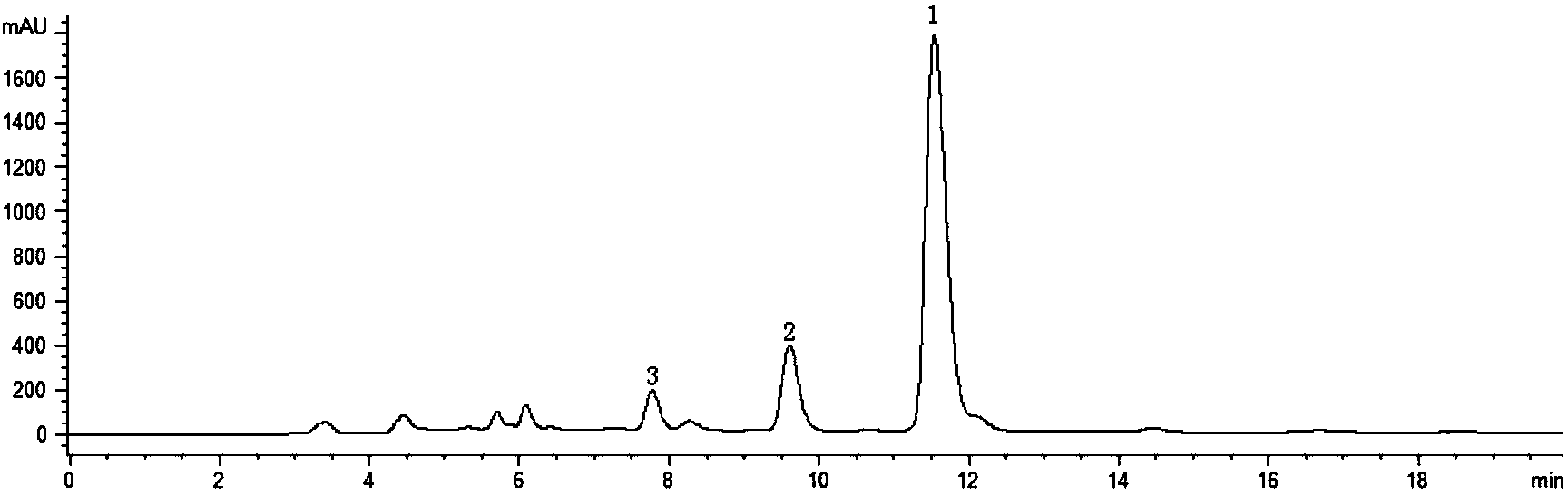

[0041] Step 2, adjust the pH of the extract to 2, pass through a 100mL macroporous adsorption resin XAD2 column (height-to-diameter ratio 8:1), elute with 50% ethanol, collect the 50% ethanol eluate step by step, detect by HPLC, and the combined purity exceeds 80% %sample.

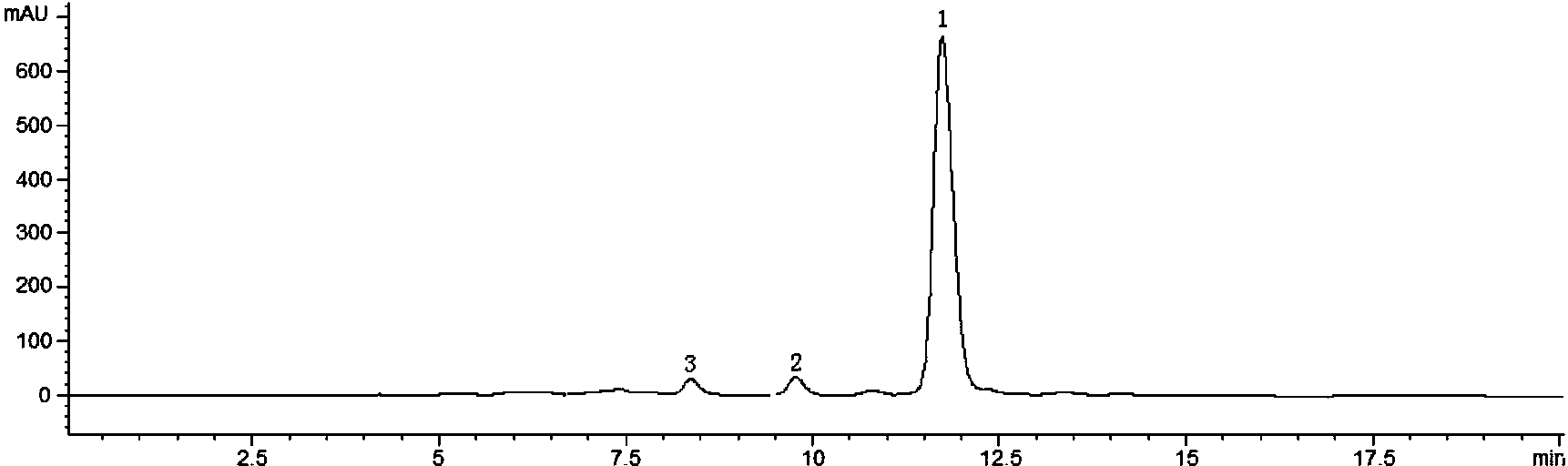

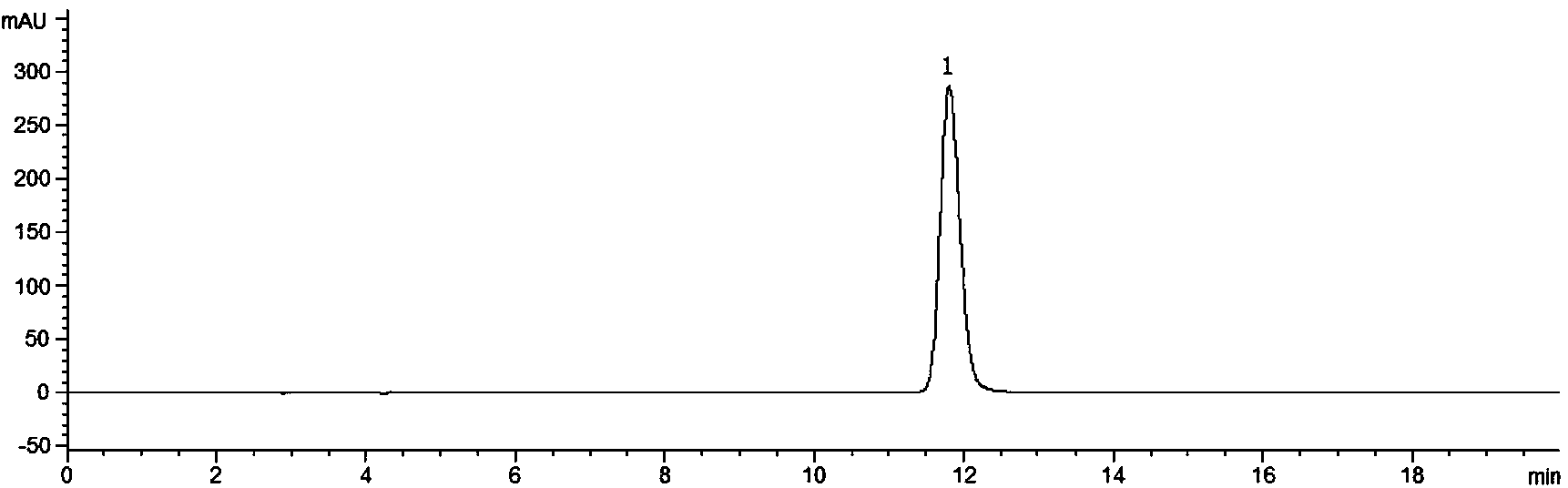

[0042] Step 3. Concentrate the above 80% salvianolic acid B ethanol solution with a purity greater than 80% to no alcohol smell, adjust to pH7, pass through 100mL microsphere resin microsphere No. 1 resin column (height-to-diameter ratio 8:1), and elute with water. Collect in steps, detect by HPLC, combine the samples with a purity exceeding 99%, and purify the samples with a purity of less than 99% by microsphere resin again. Freeze-dry the salvianolic acid B sample with a purity of 99%, and finally ob...

Embodiment 2

[0044] In Step 1 of Example 1, the extraction solvent of Salvia miltiorrhiza was replaced with 10% ethanol, and in Step 2, the macroporous adsorption resin was replaced with XAD4.

Embodiment 3

[0046] In Step 1 of Example 1, the extraction solvent of Salvia miltiorrhiza was replaced with 80% ethanol, and in Step 2, the macroporous adsorption resin was replaced with XAD16HP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com