Combined type device for plating MOF film through electrodeposition method

An electrodeposition method and a combined technology, applied in the direction of the electrode, can solve the problems of uneven stress surface and difficulty in obtaining a dense and uniform film, so as to eliminate concentration polarization, delay passivation, and facilitate extraction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

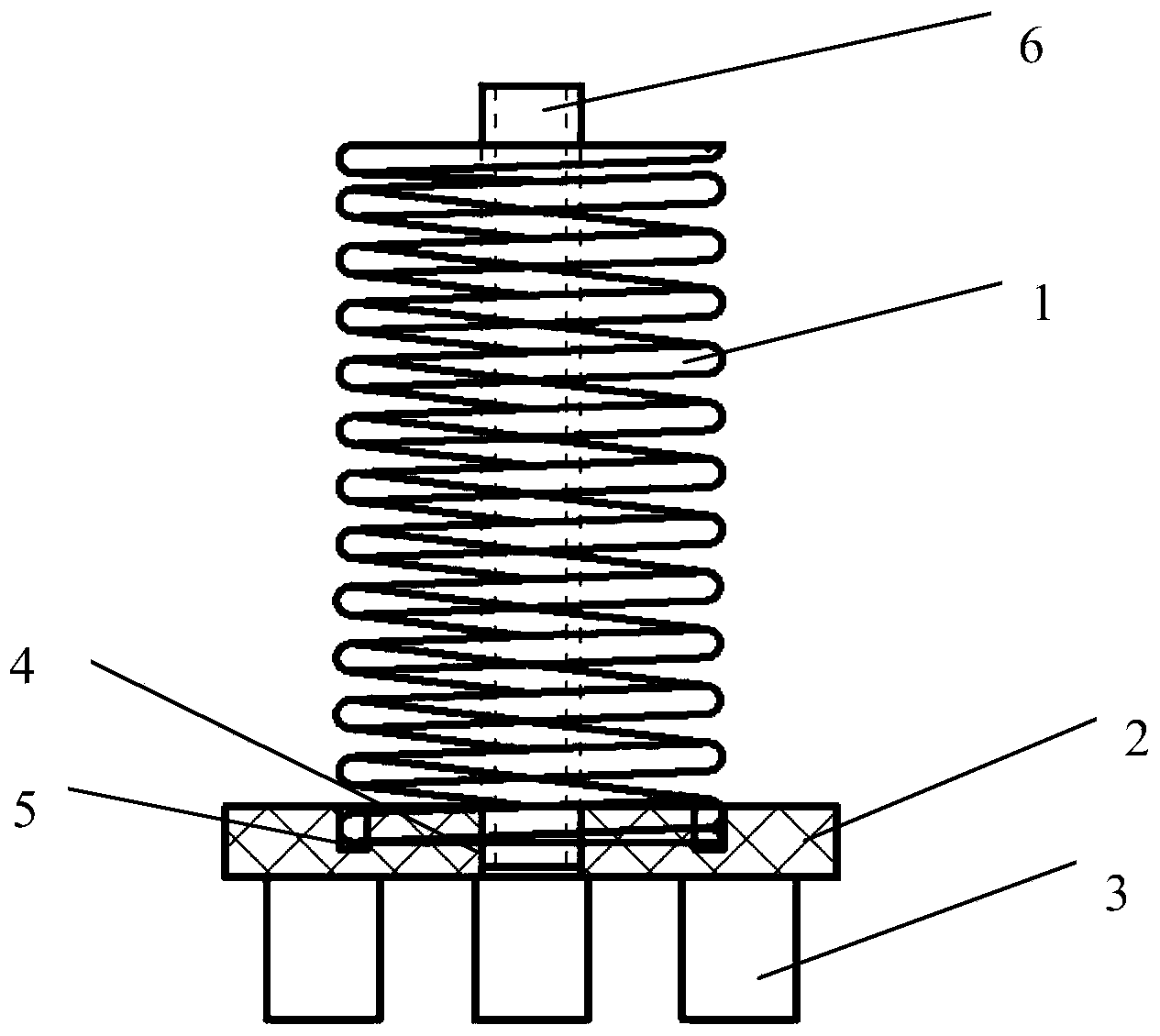

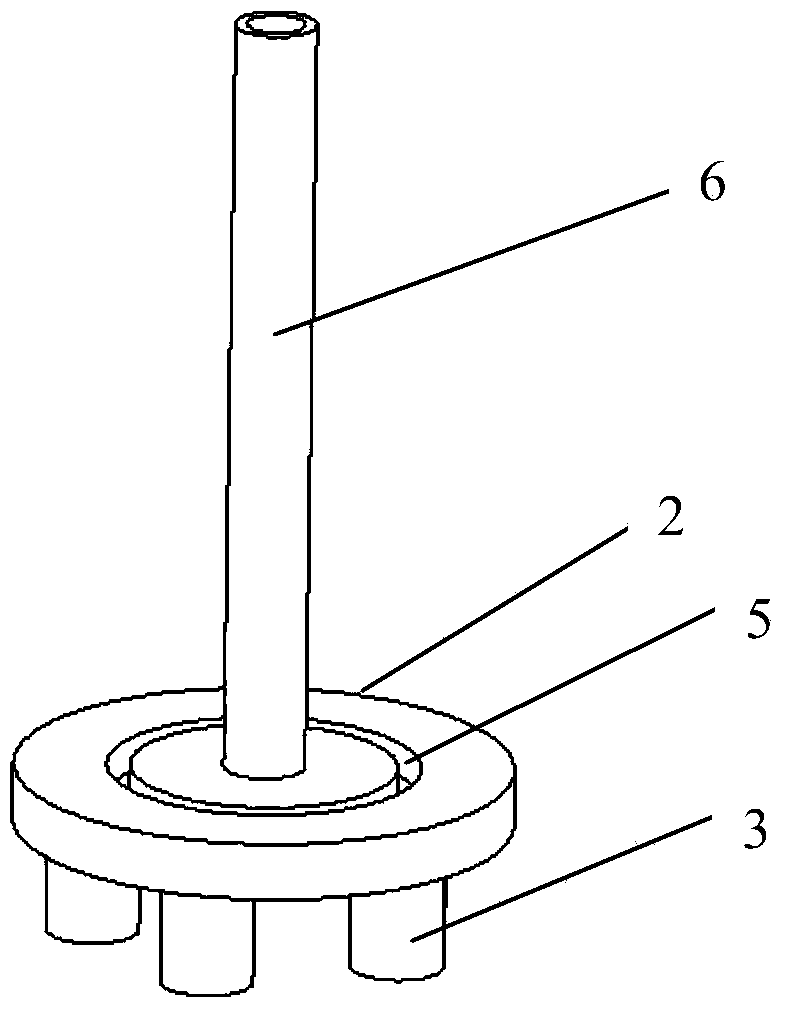

[0021] like figure 1 , 2 Shown, the present invention is used for the combined device of electrodeposition plating MOF membrane, comprises base 2, anode, cathode and the external power supply (not shown) that is connected with cathode, anode and is used for electroplating, and anode is compression spring The anode 1 and the cathode are tubular cathodes 6. A circular hole 4 for inserting the tubular cathode 6 is provided in the middle of the base 2. An annular groove 5 is provided on the base 2 with the circular hole 4 as the center of the circle. The compression spring anode 1 is embedded in the In the annular groove 5, the compression spring anode 1 and the tubular cathode 6 are equally spaced and combined.

[0022] The spring anode 1 is a material that needs to be formed into a film, and the tube-mounted cathode 6 is a carrier that needs to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com