Automatic calibration system for remote-measuring equipment

A technology of telemetry equipment and calibration system, applied in the direction of instruments, etc., can solve the problems of large impact on test accuracy, complex test process, calibration and other problems, and achieve the effect of eliminating data filling errors, improving test efficiency and high test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

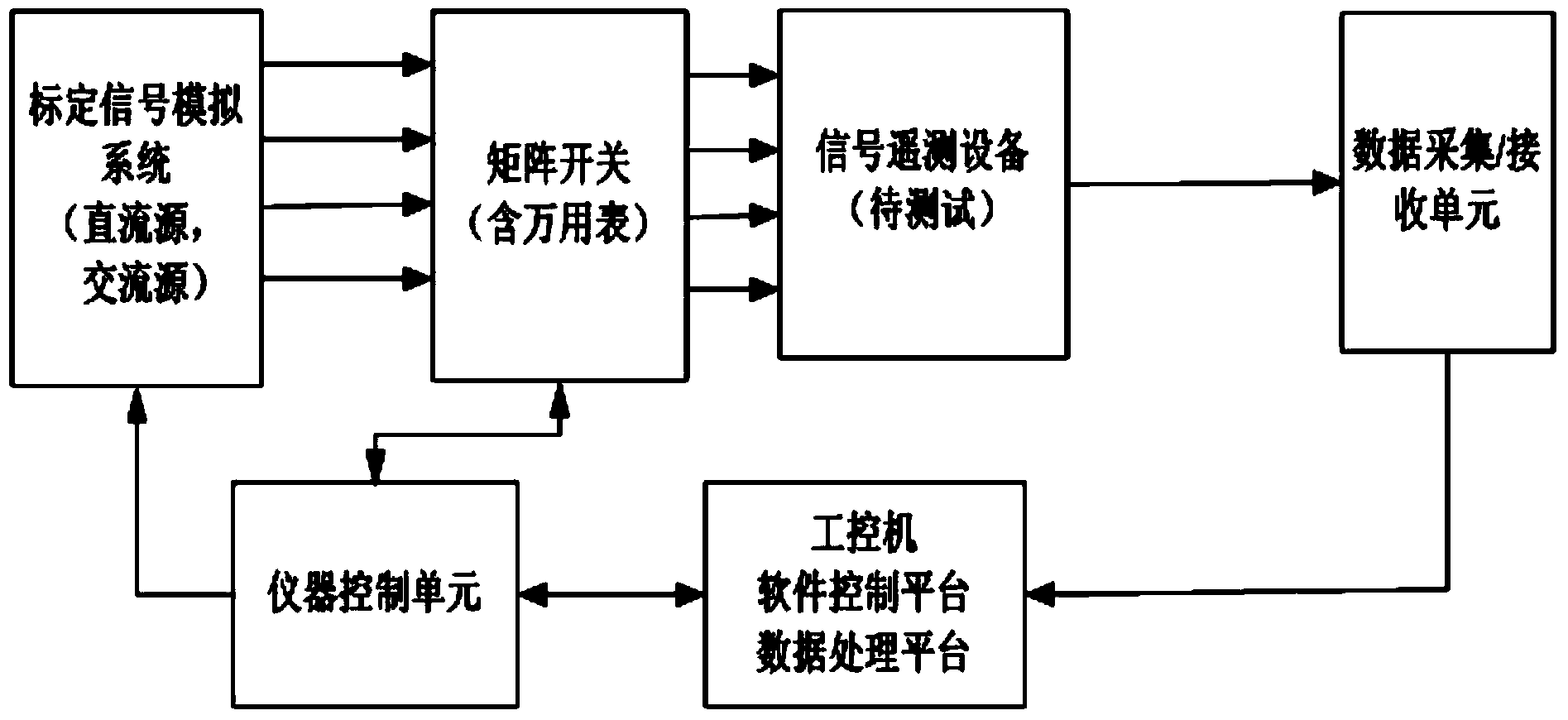

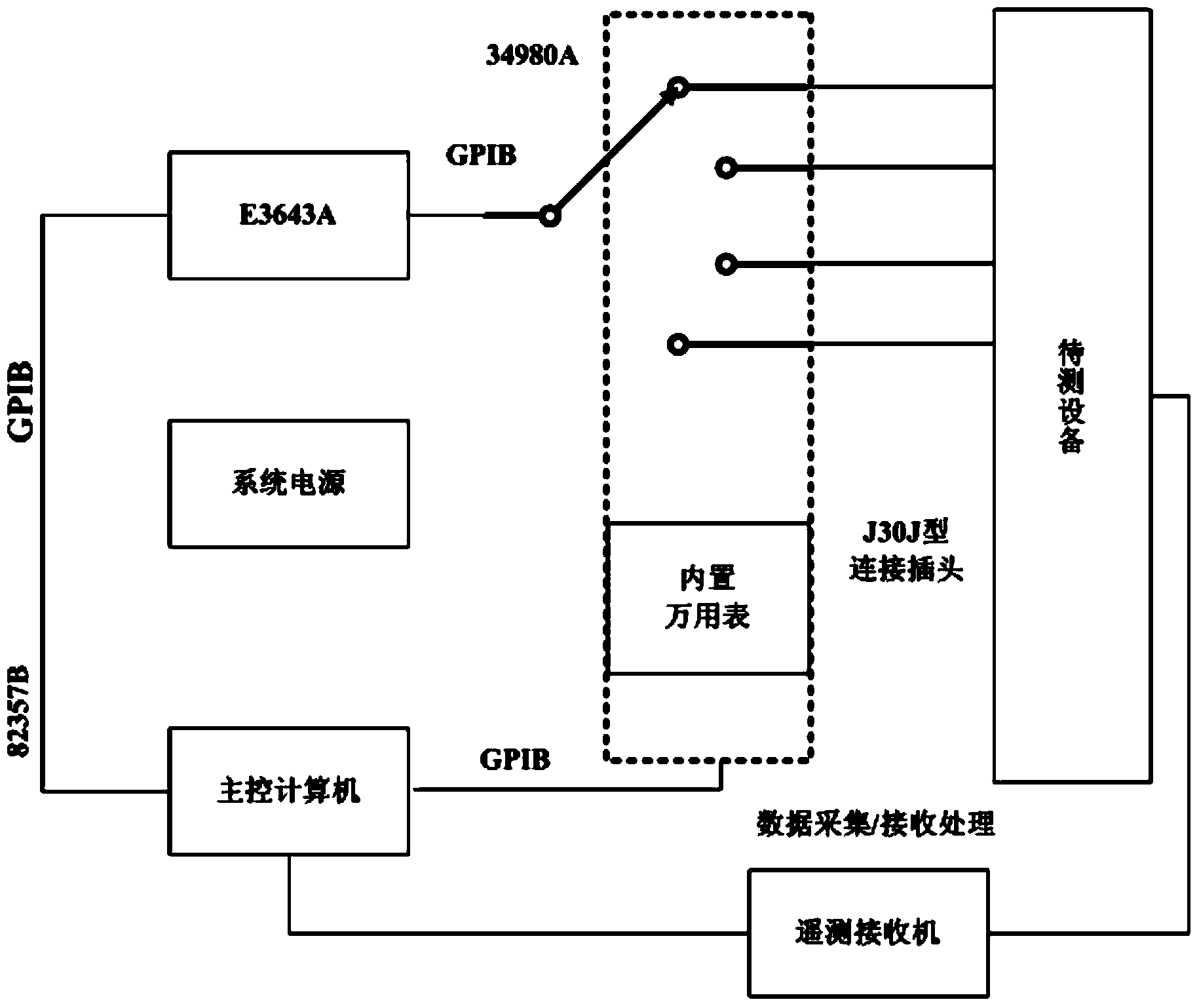

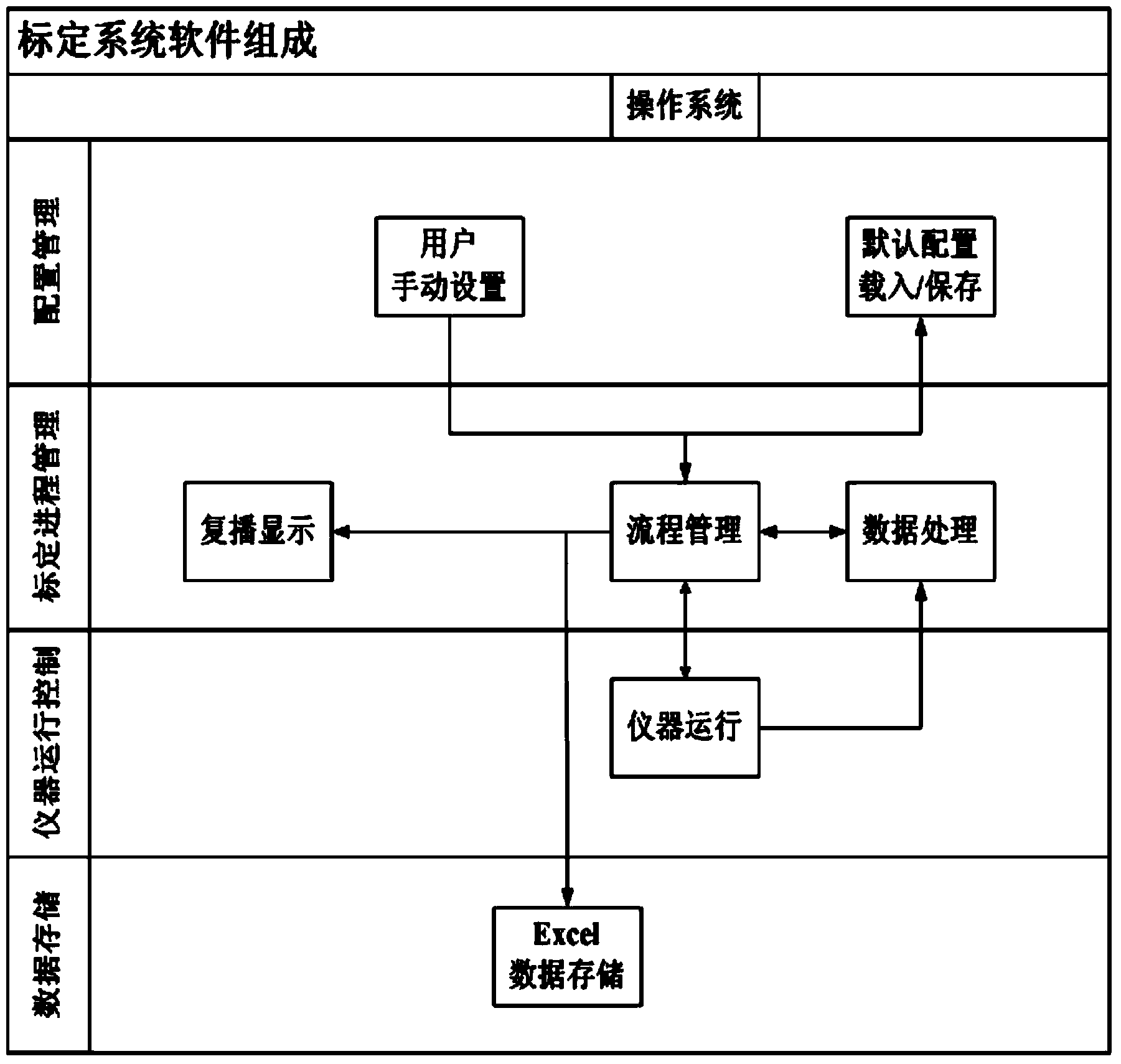

[0043] An automatic calibration system for telemetry equipment, such as Figure 1-4 shown, including:

[0044] Human-computer interaction interface, the human-computer interaction interface is used for the input of user parameters, and the user parameters are transmitted to the software control platform, and the user parameters include the setting of the channel to be tested, the setting of the mode to be tested, the calibration mode and the Set the signal source required by the measurement channel;

[0045] Calibration signal simulation system, the calibration signal simulation system is used to generate a corresponding reference signal according to the signal source parameters and calibration mode required by the channel to be tested received from the instrument control unit, and the reference signal is connected to the signal telemetry through the matrix switch Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com