Organic light-emitting diode and preparation method thereof

An electroluminescent device and luminescent technology, applied in the direction of organic semiconductor devices, organic semiconductor device materials, electric solid devices, etc., can solve the problems of material aging, failure, and short life of light-emitting devices, and achieve long life and water resistance. Oxygen corrosion, improve the effect of waterproof oxygen ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

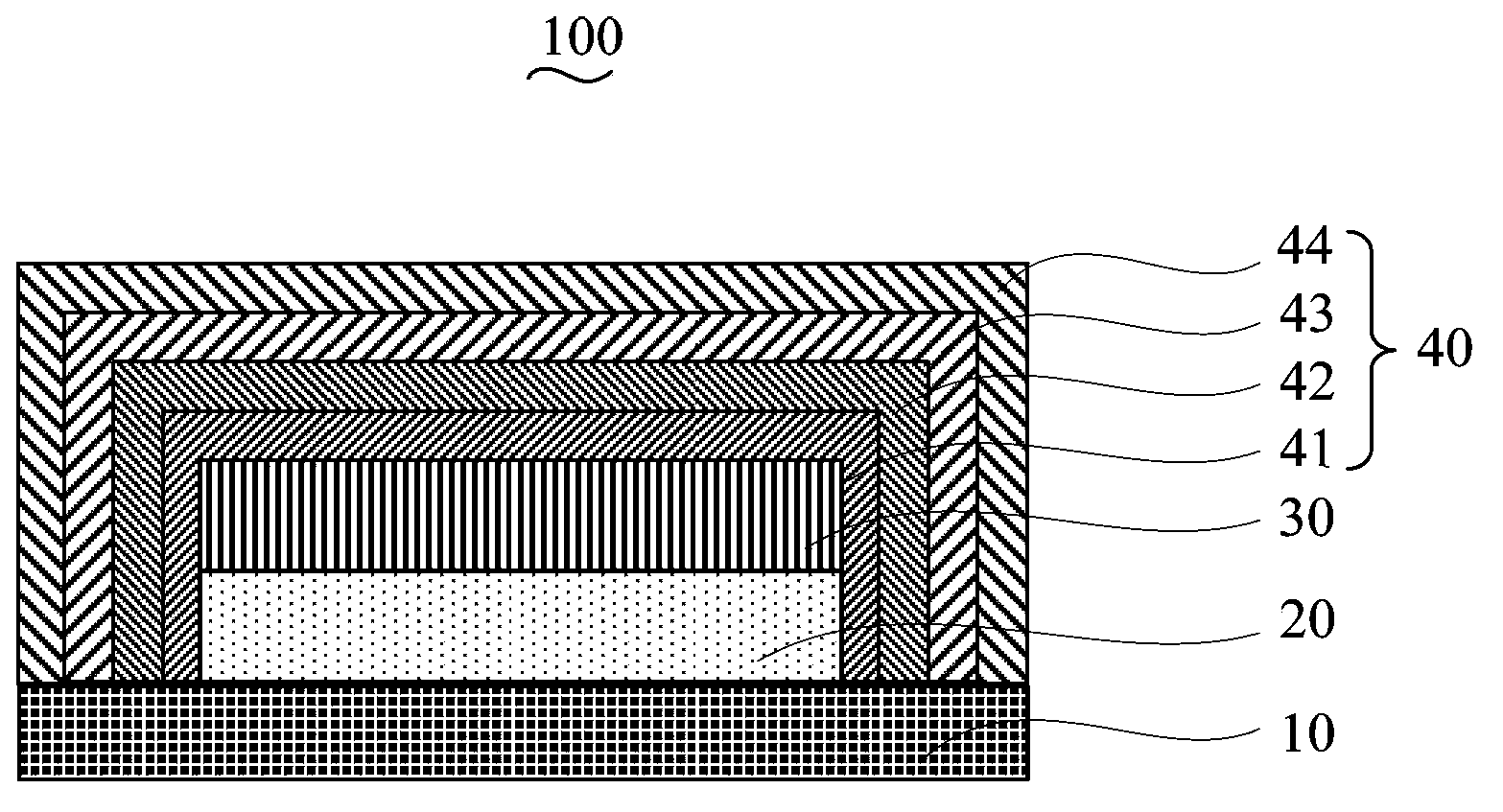

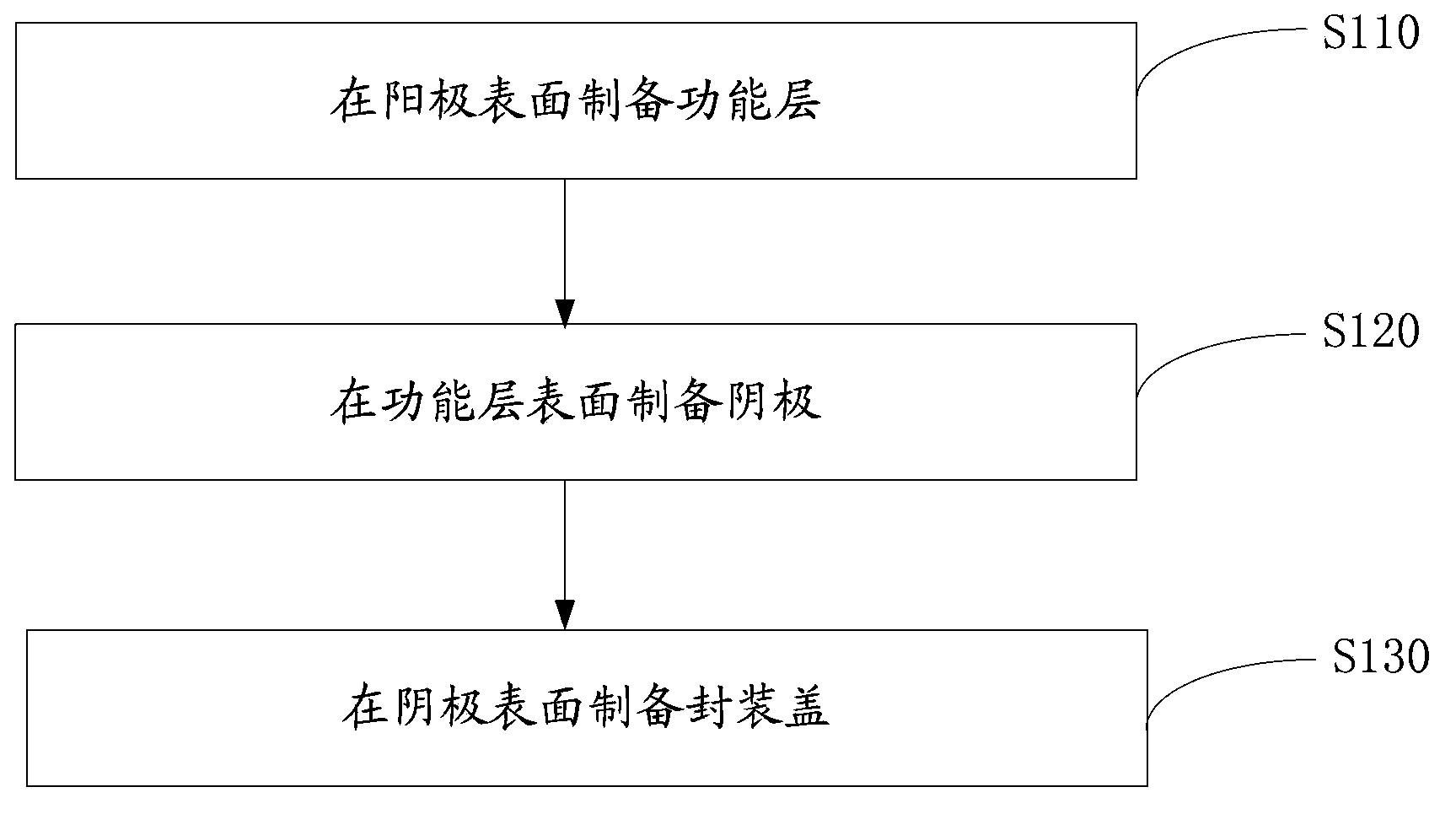

[0047] see also figure 2 , the preparation method of the organic electroluminescent device 100 of one embodiment, it comprises the following steps:

[0048] Step S110 , forming a functional layer 20 on the anode 10 .

[0049] The functional layer 20 includes a hole injection layer, a hole transport layer, a light emitting layer, an electron transport layer, and an electron injection layer stacked in this order.

[0050] The anode 10 may be a conductive glass substrate or a conductive organic polyethylene terephthalate (PET) film substrate. The anode 10 has an ITO layer prepared with an anode pattern. The thickness of the ITO layer is 100 nm to 150 nm.

[0051] Before forming the functional layer 20 , the surface of the anode 10 is pretreated to remove contaminants on the surface of the substrate 10 , and surface activation is performed to increase the oxygen content on the surface of the anode 10 to improve the work function of the surface of the anode 10 . Specifically, ...

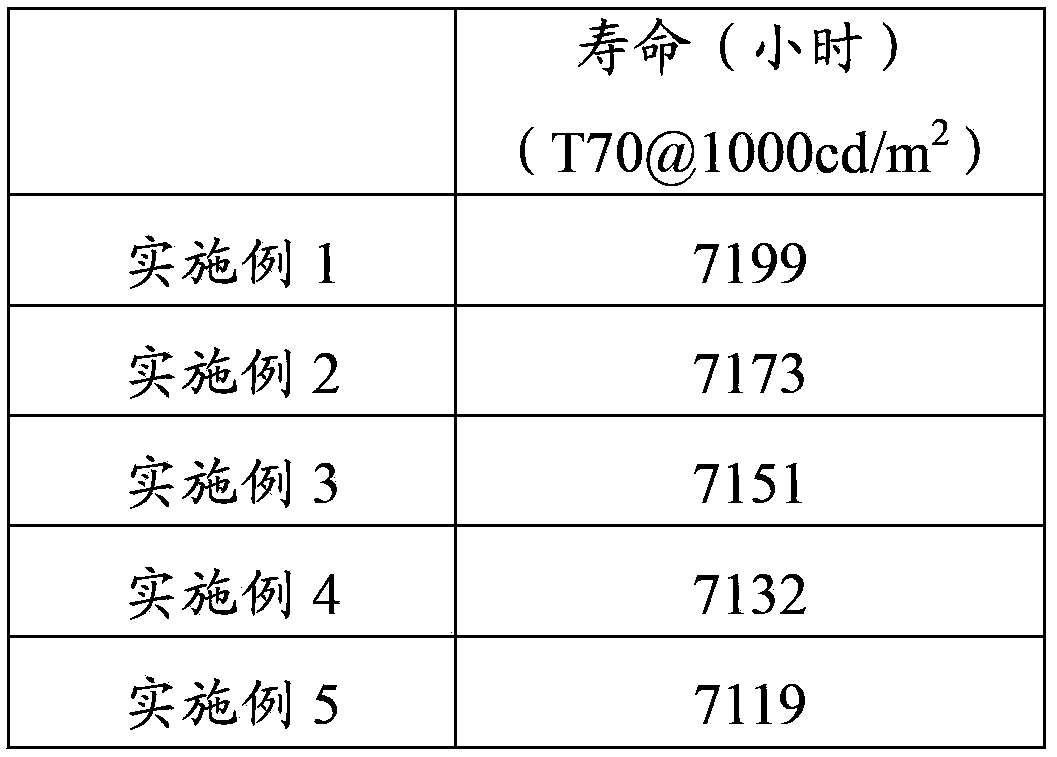

Embodiment 1

[0082] The structure prepared in this example is: ITO / NPB:MoO 3 / TCTA / TPBI:Ir(ppy) 3 / Bphen / Bphen:CsN 3 / Al / organic electroluminescent device with encapsulation cover; wherein, the slanted bar " / " indicates the layered structure, and the colon ":" indicates doping, the same below.

[0083] The preparation method of the above-mentioned organic electroluminescent device comprises the following steps:

[0084] 1. Form a functional layer on the anode.

[0085] The anode 10 is conductive glass. The anode 10 has an ITO layer prepared with an anode pattern. The thickness of the ITO layer was 150 nm.

[0086] Before forming the functional layer 20 , the surface of the anode 10 is pretreated to remove contaminants on the surface of the substrate 10 , and surface activation is performed to increase the oxygen content on the surface of the anode 10 to improve the work function of the surface of the anode 10 . Specifically, the anode 10 was successively cleaned by ultrasonic waves ...

Embodiment 2

[0103] The structure prepared in this example is: ITO / NPB:MoO 3 / TCTA / TPBI:Ir(ppy) 3 / Bphen / Bphen:CsN 3 / Al / organic electroluminescent device with encapsulation lid.

[0104] The preparation method of the above-mentioned organic electroluminescent device comprises the following steps:

[0105] 1. Form a functional layer on the anode.

[0106] The anode 10 is conductive glass. The anode 10 has an ITO layer prepared with an anode pattern. The thickness of the ITO layer was 120 nm.

[0107] Before forming the functional layer 20 , the surface of the anode 10 is pretreated to remove contaminants on the surface of the substrate 10 , and surface activation is performed to increase the oxygen content on the surface of the anode 10 to improve the work function of the surface of the anode 10 . Specifically, the anode 10 was successively cleaned by ultrasonic waves for 5 min to remove acetone, ethanol, ionized water and ethanol, and then dried with nitrogen and oven dried.

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com