Light blue film for grape cultivation

A kind of grape and light technology, which is applied in the field of light blue film for viticulture, can solve the problems that light waves cannot act, light hinders, hinders plant growth, etc., and achieves the goals of inhibiting plant growth, increasing anthocyanin content, and promoting accumulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

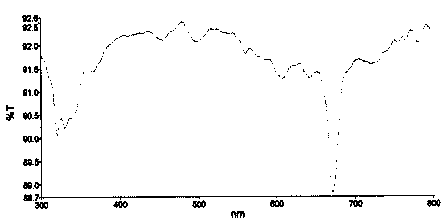

Image

Examples

Embodiment 2

[0014] Embodiment 2 A light blue film for viticulture is made of the following raw materials in weight percentage: LLDPE70%, LDPE 20%, film function masterbatch for viticulture 10%; described film function masterbatch for viticulture is made of The raw material of following percentage by weight is made: LLDPE powder material carrier 75%, light stabilizer 6%, antioxidant 2%, dripping agent 13%, insulation agent 4%; Then add phthalocyanine blue in described raw material, it adds The amount is to add 10 grams of phthalocyanine blue per ton of raw materials, wherein the thickness of the light blue greenhouse film is controlled at 0.04mm.

[0015] The comparative example adopts the common white conventional film on the market.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com