Liquid metal purification device

A liquid metal and purification device technology, applied in the field of metallurgy, can solve the problems of insufficient capacity to accommodate filter residues, limit the filtration capacity of filter elements, and frequently replace filter elements, etc., to achieve the advantages of solid impurities settlement, simple heating scheme, and simple slag discharge operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] Liquid metal purification is mainly to remove solid particle impurities in liquid metal. If there are many solid particles passing through the filter element 6, the filter holes will be blocked quickly, which will affect the filtering capacity and filtering efficiency of the filter element 6.

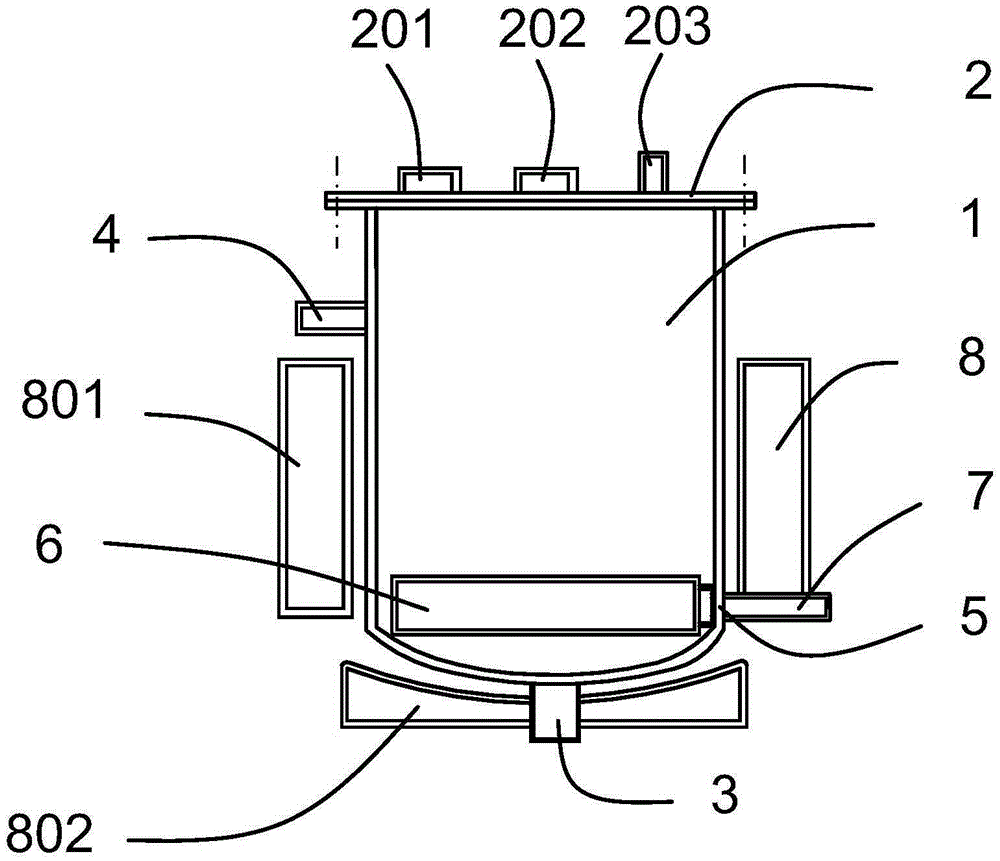

[0036] In order to ensure that the filter core 6 has good filtration capacity and filtration efficiency, as preferred, as figure 1 As shown, there is a space between the filter element 6 and the bottom of the still body.

[0037]When the filter element 6 is arranged in the kettle body 1 close to the bottom of the kettle body, a certain volume space is reserved between the bottom of the kettle body and the lower part of the filter element 6, and this space is also the sedimentation area of solid particle impurities. The size of the volume space is determined by the distance between the filter element 6 and the bottom of the still body. This distance is determined according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com