Induction heating and refining device with tundish and channels shaped like Arabic number eight

A technology of induction heating and refining equipment, applied in metal processing equipment, casting melt containers, manufacturing tools, etc., can solve the problems of large overall structure of equipment, large cooling system structure, unfavorable technical transformation, etc., and improve surface and internal quality , to meet the cooling effect, the effect of small heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to understand the technical content of the present invention more clearly, the following embodiments are specifically described in detail.

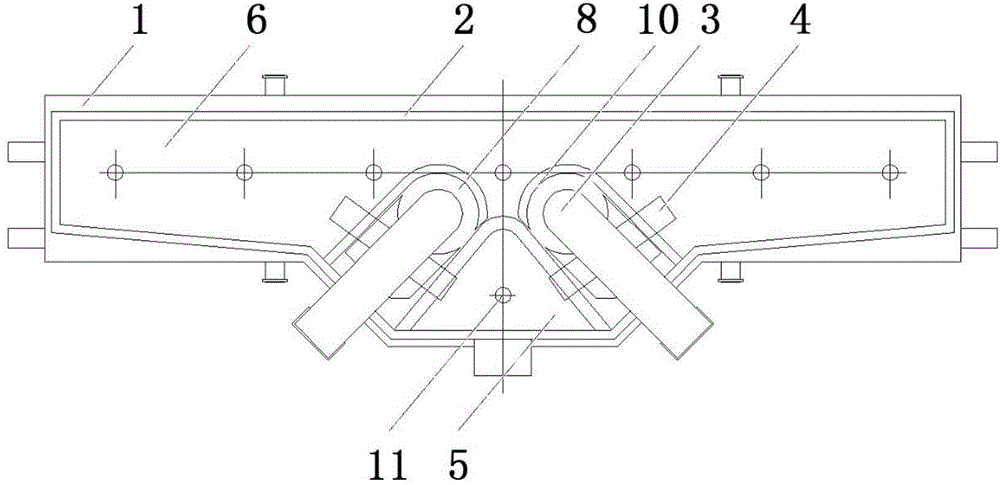

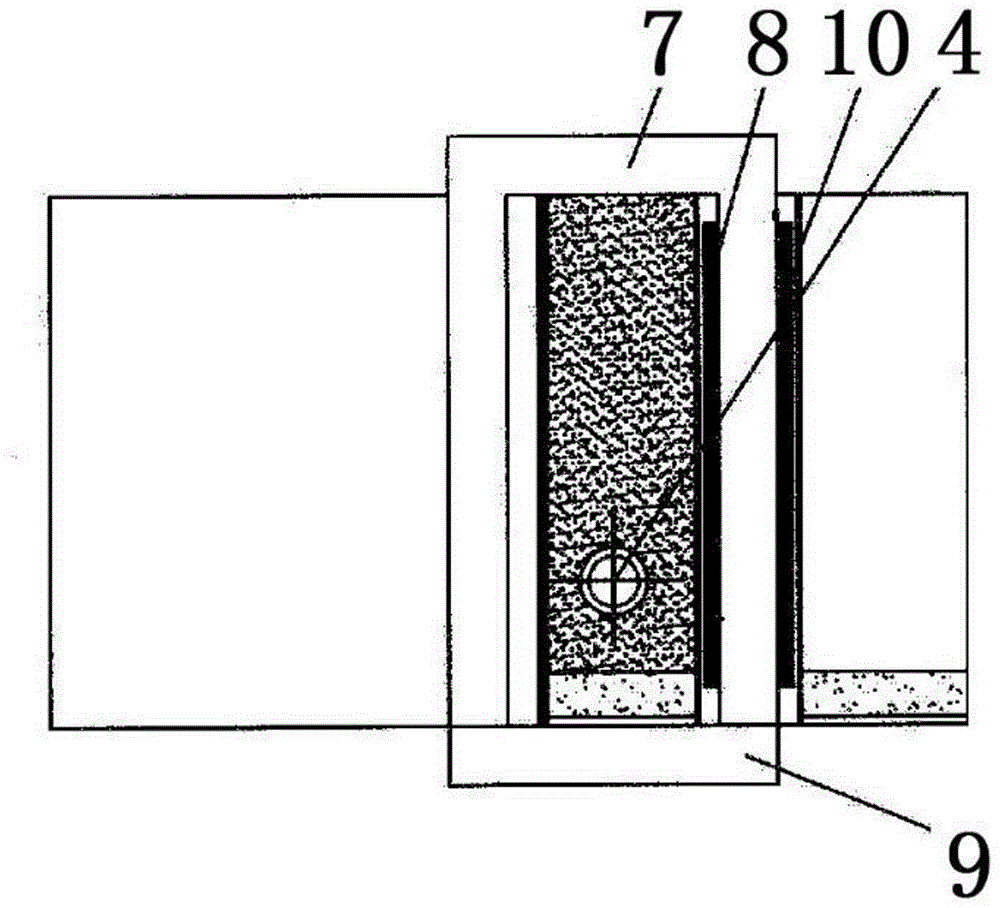

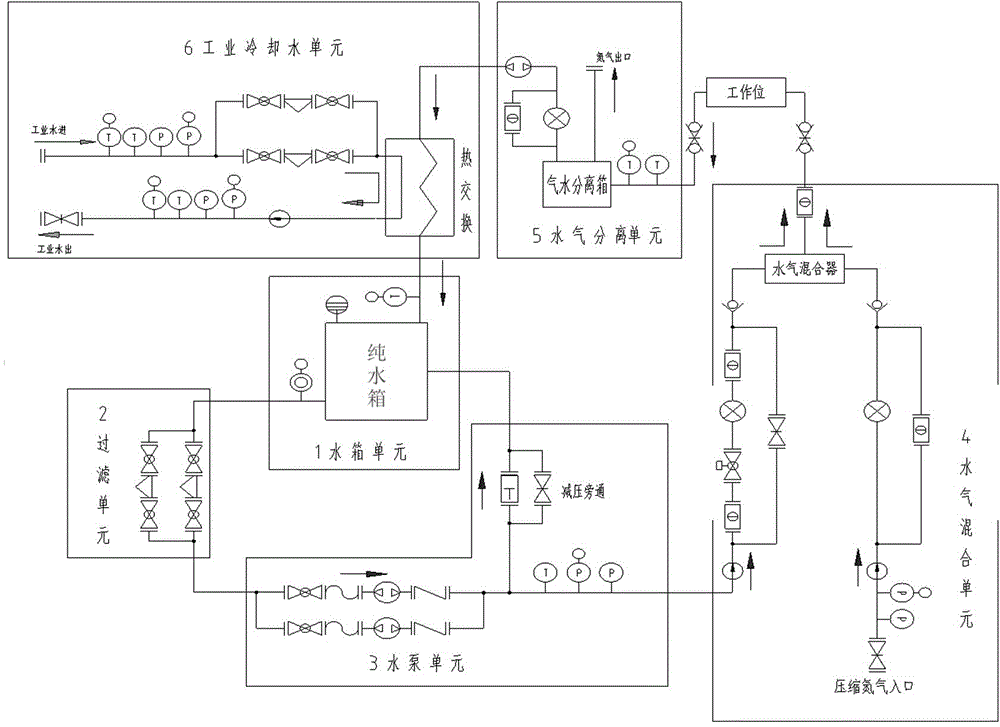

[0025] by figure 1 , figure 2 with image 3 It can be seen that a tundish eight-shaped channel induction heating and refining device includes a composite cooling system, two molten steel channels 4 and an induction heater 3. The molten steel channel 4 is connected to the ladle injection chamber 5 and the pouring chamber 6 of the tundish. The molten steel channel 4 is arranged in a figure eight shape between the ladle injection chamber 5 and the pouring chamber 6, an induction heater 3 is arranged around a molten steel channel 4, or two molten steel channels 4 are respectively surrounded by an induction heater 3 The induction heater includes a gate-shaped iron core 7 with an open lower end, a coil 8 and a yoke 9. The coil 8 is wound on the side of the gate-shaped iron core 7, and the yoke 9 is arranged at the opening of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com