Biological contact oxidation process suspension type filler fixing device

A suspension device and biological contact technology, applied in the field of water treatment, can solve the problems of heavy packing and support system, inconvenient maintenance and repair, complex structure, etc., to avoid daily rust prevention workload, convenient operation and maintenance, and simple installation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

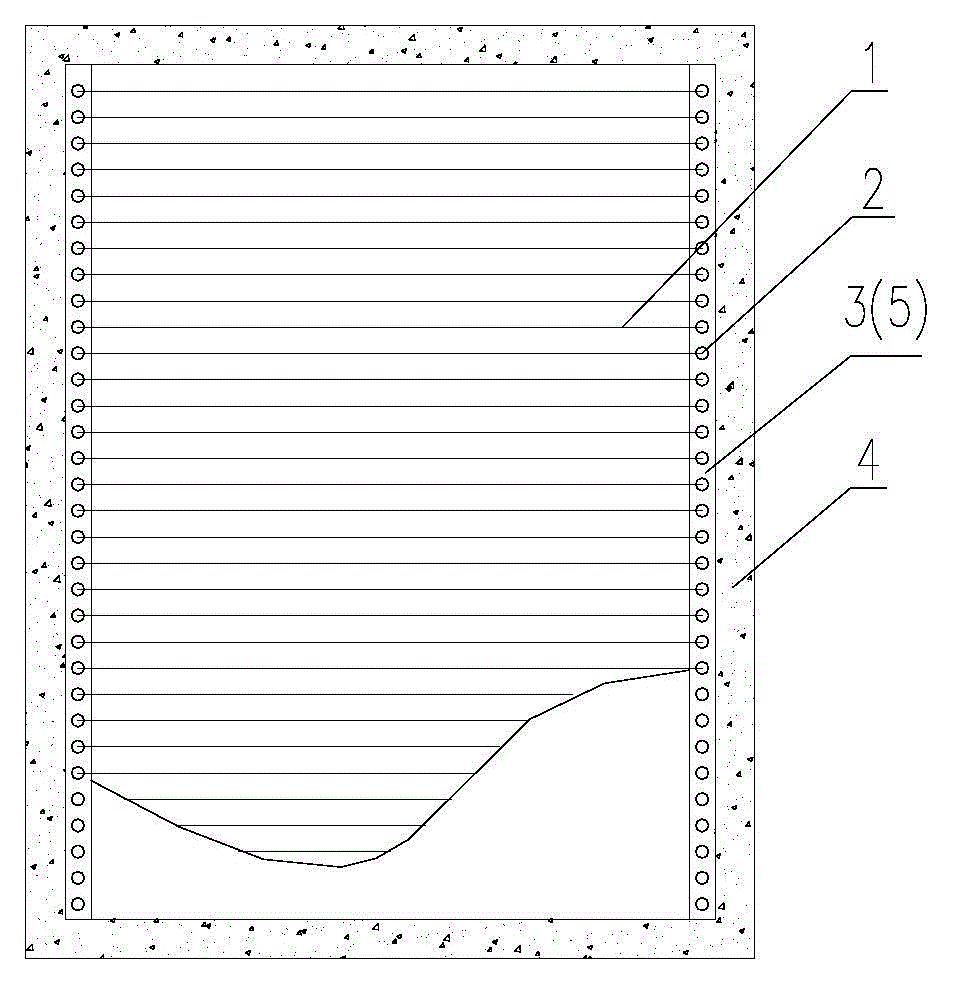

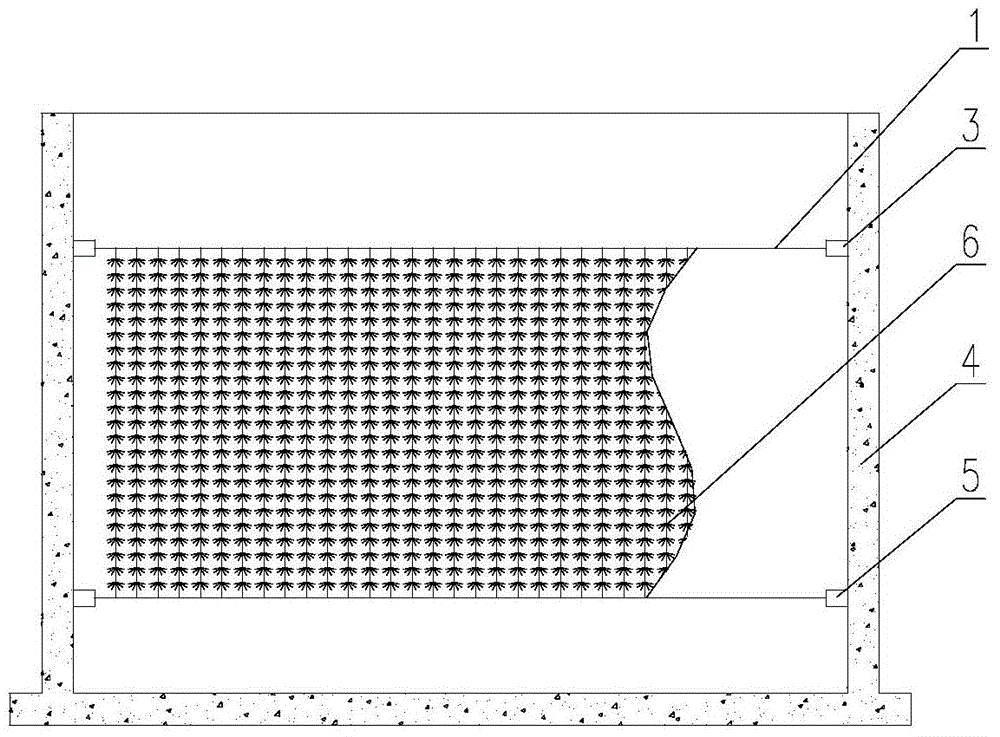

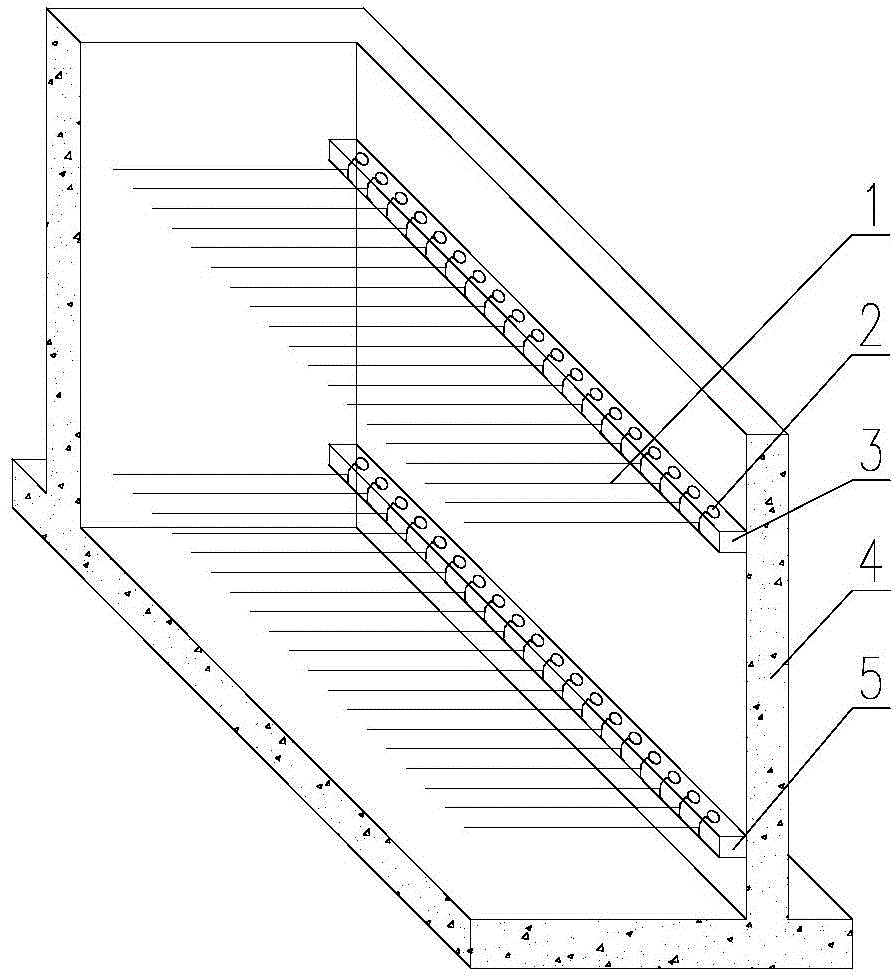

[0019] Such as Figure 1-3 A kind of suspended filler fixing device of the biological contact oxidation method shown, the upper suspension device 3 and the lower suspension device 5 are arranged on the pool walls 4 on opposite sides of the oxidation tank, the lower suspension device 5 is 0.5 meters away from the bottom of the pool, and the upper suspension device 3 The distance from the lower suspension device 5 is 3 meters, and the upper and lower suspension devices are provided with holes 2 for fixing the rope 1, and the distance between the holes is 150 millimeters. There is an upper rope, and a lower rope is tied between the holes of the lower suspension device 5 on opposite sides of the pool wall, and the fixed filler 6 is hung vertically and equally spaced between the upper rope and the lower rope; the upper suspension device 3 and the lower suspension The device 5 is a reinforced concrete structure, which is cast integrally with the pool body at the same time. The rope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com