Etching method and equipment of etching stainless steel by ferric chloride

A technology of ferric trichloride etching and ferric chloride, which is applied in the field of stainless steel etching, can solve the problems of unguaranteed etching quality and short service life of etched stainless steel, and achieve the effects of improving product quality, increasing production capacity, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and preferred specific embodiments of the present invention.

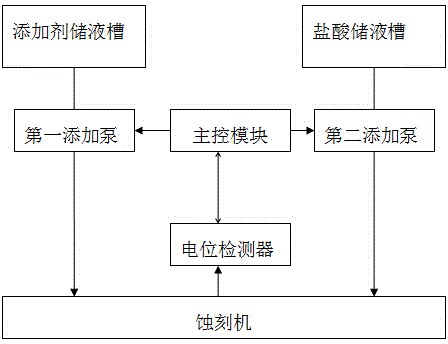

[0016] refer to figure 1 As shown in, the etching equipment of the present invention includes an etching machine, and a potential detector is provided in the etching machine, and the potential detector is used to detect the ORP (Oxidation-Reduction Potential redox potential) value of the ferric chloride etching solution in the etching machine; Two 150-liter capacity additive storage tanks and hydrochloric acid storage tanks are arranged next to the etching machine. The additive storage tanks are used to store additives. The additives are preferably sodium chlorate, and industrial hydrochloric acid with a concentration of ≥30% in the hydrochloric acid storage tank. The additive liquid storage tank and the hydrochloric acid liquid storage tank are respectively connected with the etching machine through the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com