Angle adjustable type magazine tool assembly for bituminous pavement cold milling machine

A technology of cold milling machine and asphalt pavement, which is applied in the field of asphalt pavement milling, and can solve problems such as unreasonable design of tool installation angle and eccentric grinding angle, inability to adjust the installation angle and eccentric grinding angle, and large fluctuations in milling load. It is easy to achieve the angle adjustment range, the adjustment effect is good, and the effect of simplifying the difficulty of processing is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

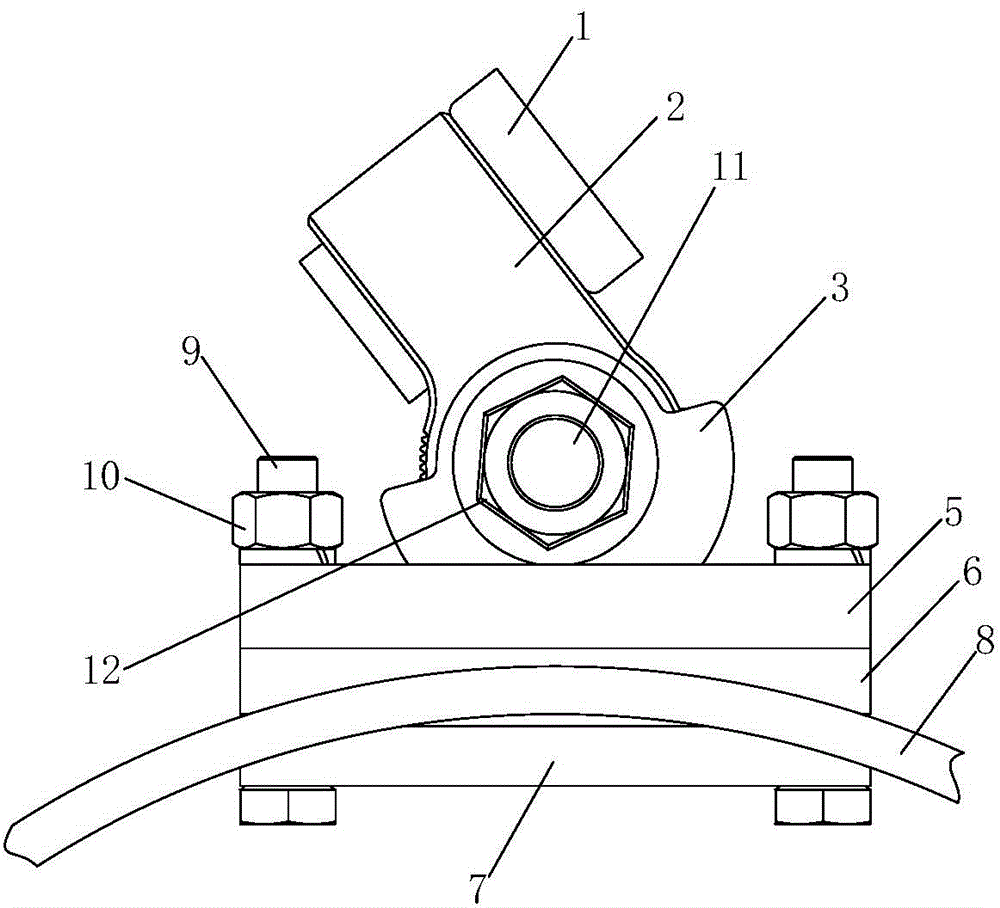

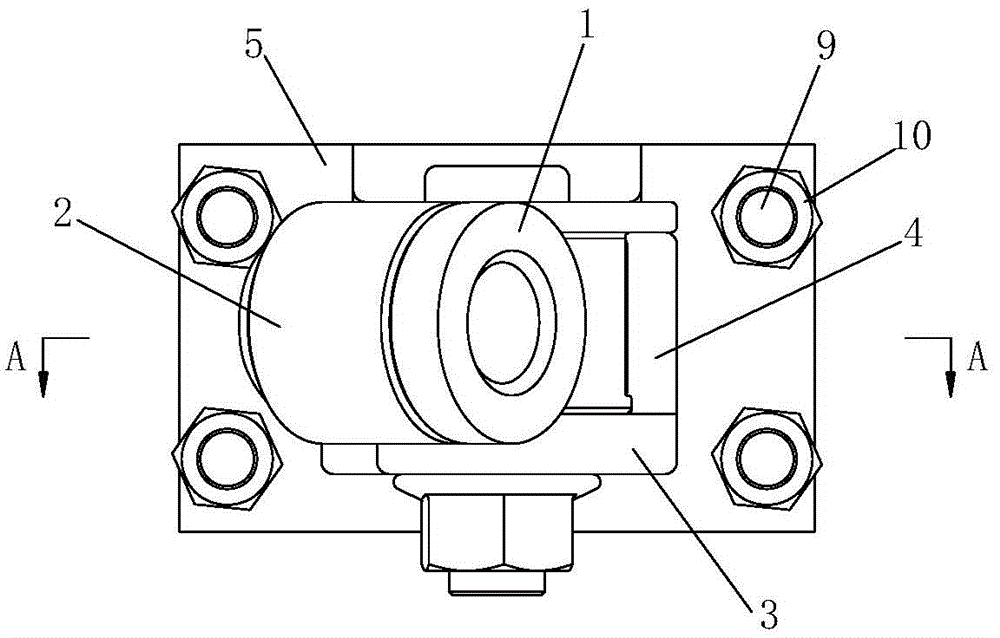

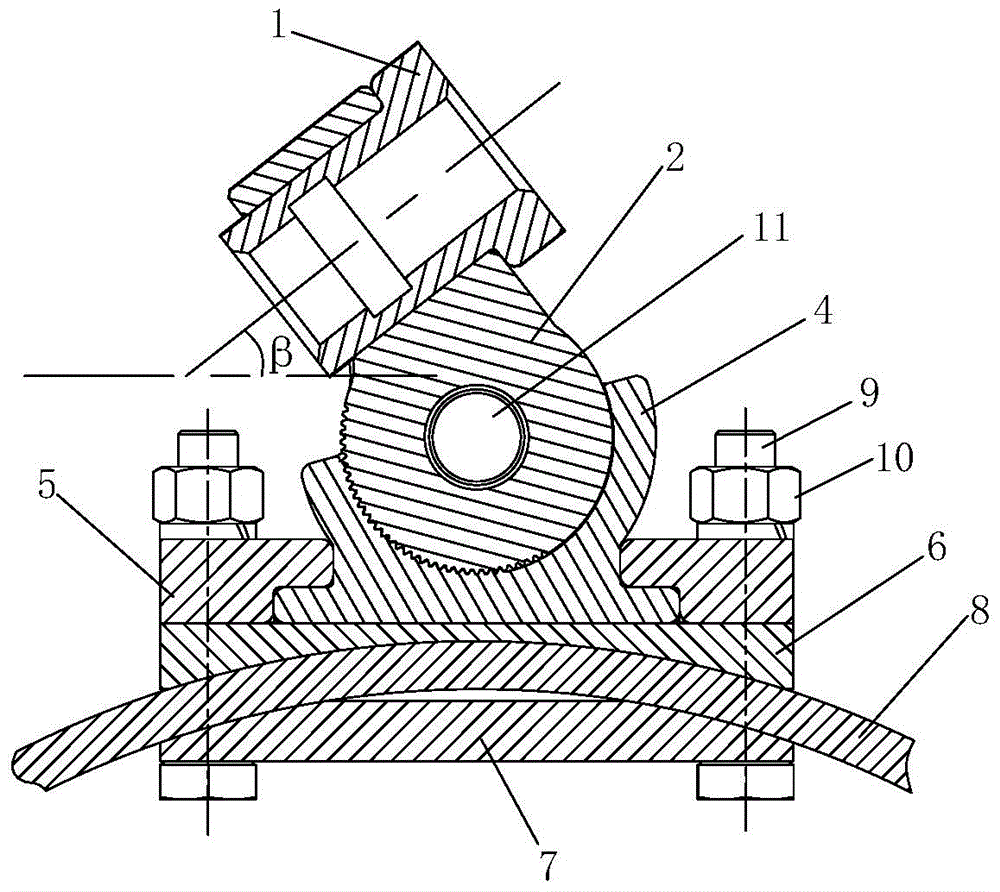

[0050] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 8 with Figure 9 An angle-adjustable tool magazine assembly for an asphalt pavement cold milling machine is shown, including a tool seat 2, a mounting seat 4 and a base, and a milling tool 14 installed on the upper end of the tool seat 2, the base The base is installed on the milling drum 8 of the cold milling machine for asphalt pavement. The base is provided with an oblique T-shaped groove 13 that is engaged with the mounting base 4. The mounting base 4 is provided with an arc groove 4. -1, the knife seat 2 is provided with a knife seat main body 2-1 for extending into the arc groove 4-1, the knife seat main body 2-1 and the groove wall of the arc groove 4-1 Key fit, the mounting seat 4 is provided with a bolt connection part 4-3 located on the side of the tool holder body 2-1, and the bolt connection part 4-3 and the tool holder body 2-1 are connected by bolts 11 connection, the milling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com