Belt type large-power resistor

A technology of high-power resistance and layer resistance, applied in the direction of bendable/foldable resistors, etc., can solve the problems of life damage of surrounding vital components, complex resistance structure, cumbersome production process, etc., to achieve stable resistance, high conductivity, The effect of reducing material and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

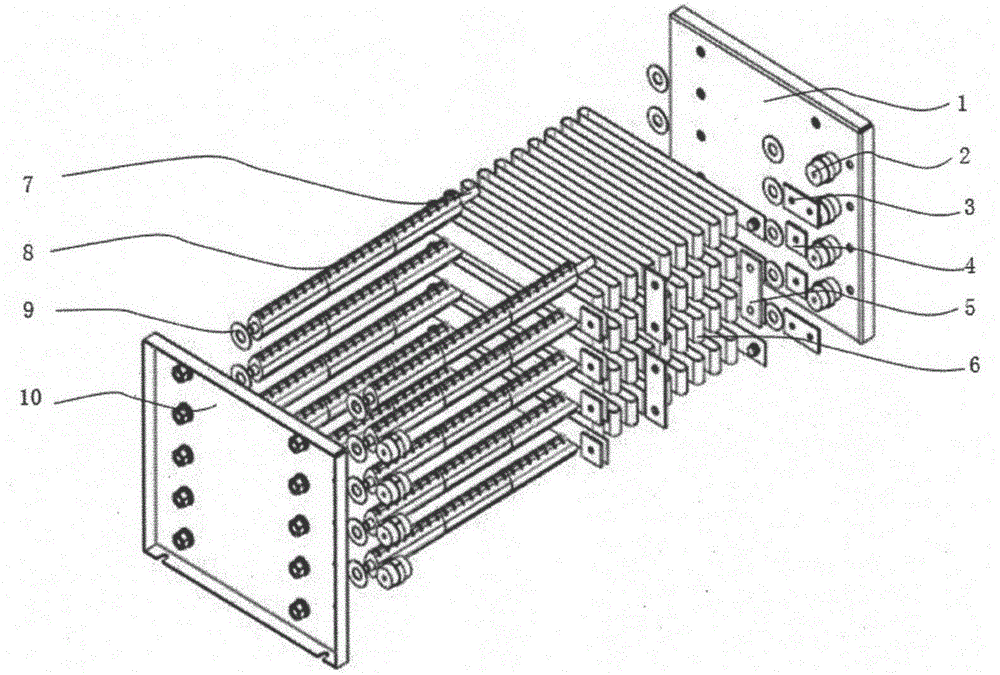

[0013] See figure 1 , The ribbon resistor provided by the present invention includes multiple resistor ribbons 6 connected in series and in parallel, and all the resistor ribbons 6 are combined by using a ceramic piece 8 . Wherein, the material of the resistance band 6 is a stainless steel band or a nickel-chromium band or the like.

[0014] In the strip resistor provided by the present invention, the stainless steel strip is the conductive resistance material, and different resistance values, temperature drift performance, and energy can be achieved by changing the material of the resistance strip 6 or connecting in series or parallel. Generally, the strip material used for the resistance band 6 is SUS304, and other grades of stainless steel, iron-chromium-aluminum alloy and nickel-chromium alloy can also be used. In order to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com