Single Turbine Solar Greenhouse Roller Shutter

A technology for solar greenhouses and rolling shutters, which is applied in the field of agricultural machinery, and can solve problems such as damage to the connection between the reducer and the reel, easy damage to the rolling shutters, and increased transportation and installation costs. The effect of installation labor and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

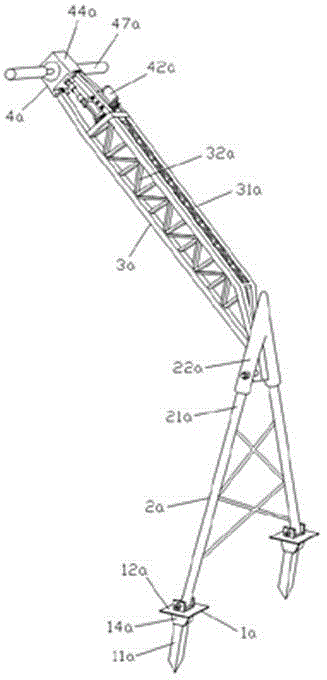

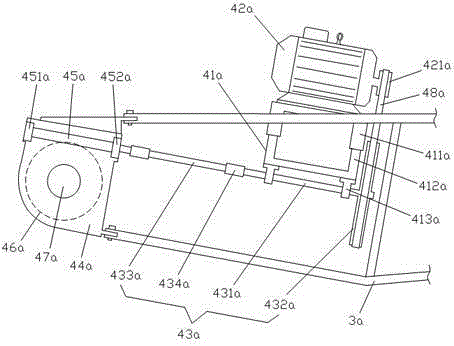

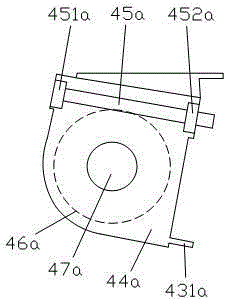

[0048] Such as Figures 1 to 7 As shown, the single-turbine solar greenhouse roller shutter machine according to Embodiment 1 of the present invention includes an anchor frame 1a, a support frame 2a, a torsion frame 3a and a roller shutter mechanism 4a.

[0049] The anchor frame 1a is a pair fixed on the ground, and each of the pair of anchor frames 1a includes a vertical plate 11a, an anti-sinking plate 12a, a U-shaped clip 13a and an anti-moving plate 14a. The vertical plate 11a is formed by connecting two rectangular plates at a certain angle, preferably 90°, and its bottom end is tapered. The anti-sinking plate 12a has a rectangular plate structure as a whole, and is fixed horizontally on the top of the right-angled vertical plate 11a. The U-shaped clip 13a is installed on the top surface of the anti-sinking plate 12a, and it is a rectangular steel plate with two ends symmetrically bent at 90°, including a base plate 131a and a pair of vertically extending from both en...

Embodiment 2

[0063] Such as Figures 8 to 11 As shown, the single-turbine solar greenhouse roller shutter machine of Embodiment 2 of the present invention also includes anchor frame, support frame, anti-torsion frame 3b and roller shutter mechanism 4b; wherein, the single-turbine solar greenhouse roller shutter of Embodiment 2 of the present invention The structure of the anchor frame, support frame, and torsion frame 3b of the machine is exactly the same as that of the corresponding anchor frame 1a, support frame 2a, and torsion frame 3a in Embodiment 1 of the present invention, and will not be repeated here.

[0064] The difference between Embodiment 2 of the present invention and Embodiment 1 is that the structure of the rolling shutter mechanism is different, that is, the rolling shutter mechanism 4b of Embodiment 2 of the present invention is also installed at one end of the anti-torsion frame 3b, which includes a motor 41b, an intermediate shaft assembly, an assembly Box 43b, scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com