High-strength combined self-degrading expansion bone peg

A combined, self-degrading technology, applied in the fields of internal bone synthesis, medical science, fastening devices, etc., can solve the problems of non-self-degradation and easy slippage of bone nails, achieving long degradation cycle, avoiding slippage, and good corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

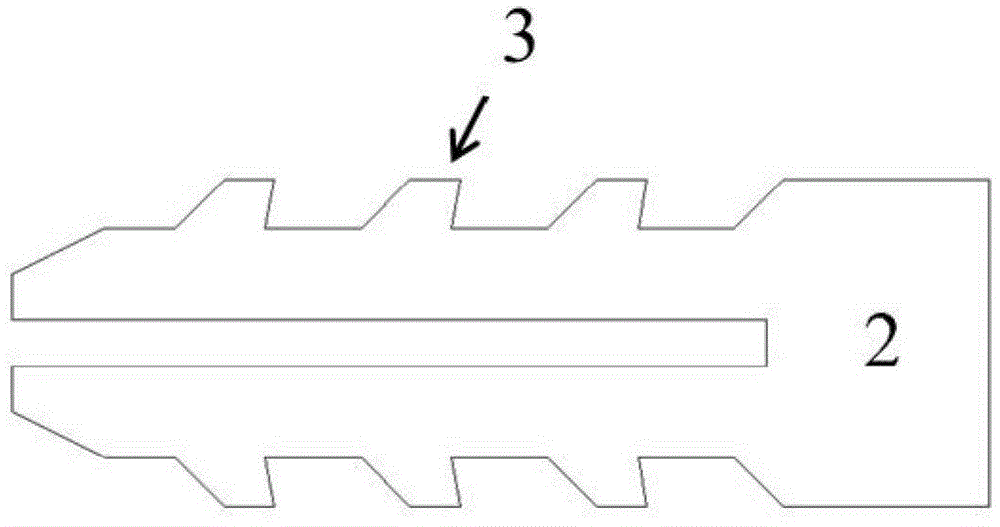

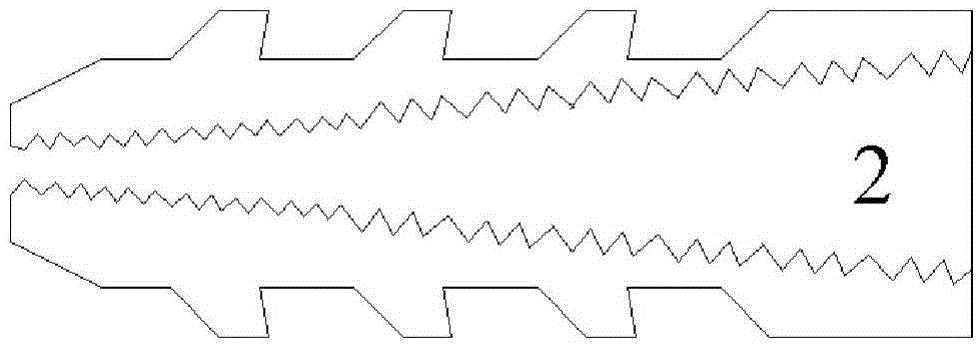

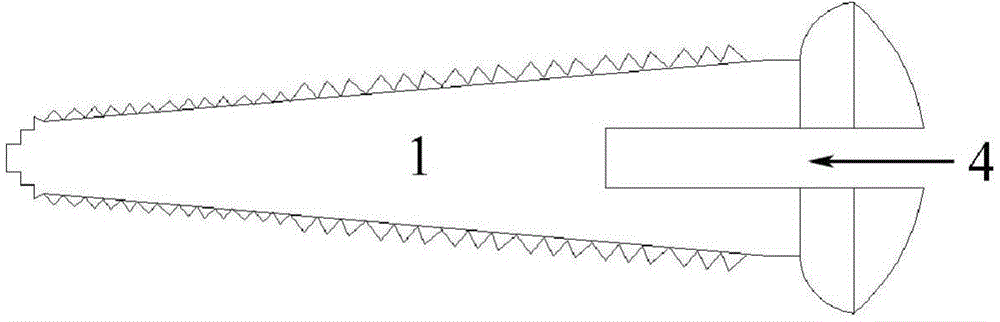

[0023] The schematic diagram of the structure of the high-strength combined self-degrading expansion bone nail described in Example 1 is shown in figure 1 , figure 2 and image 3 .

[0024] exist figure 1 The outer surface of the polylactic acid expansion-type internal thread cavity is a trapezoidal inverted triangle wedge 3, and the angle between it and the surface of the thread cavity is between 70° and 90°. There is a slot at the front end.

[0025] exist image 3 The outer surface of the bone nail body 1 shown has deep threads and shallow threads, and the top of the nail body is a spherical head type cap, and the cap is provided with an inner triangular hole groove.

[0026] When the bone nail body 1 has not been screwed into the expandable internal thread cavity 2, the front end of the thread cavity is in a state of not being stretched by the nail body. The length of the bone nail body 1 is L=10mm-120mm, the diameter of the spherical head is D=6mm-12mm; the depth o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com